A Forming Process for Uniform Spinning of Titanium Alloy Sheet by Cluster Steel Ball Half-mold

A sheet forming, titanium alloy technology, applied in the field of uniform spinning titanium alloy sheet forming process of clustered steel ball half molds, can solve the problems of low forming precision and poor quality, and achieve good forming ability, small structure, and convenient mold replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

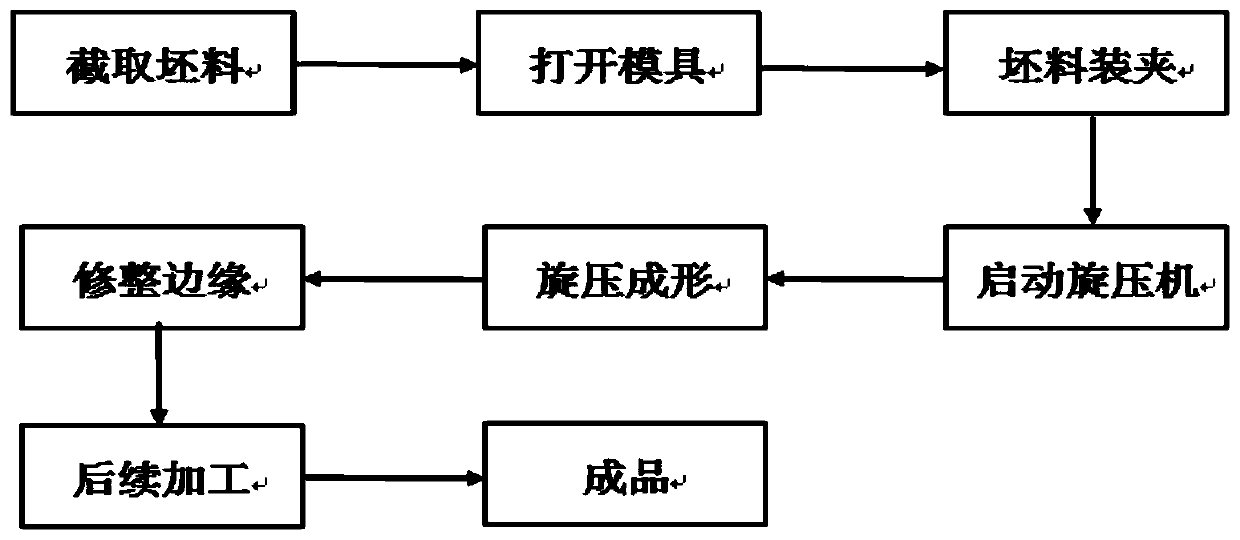

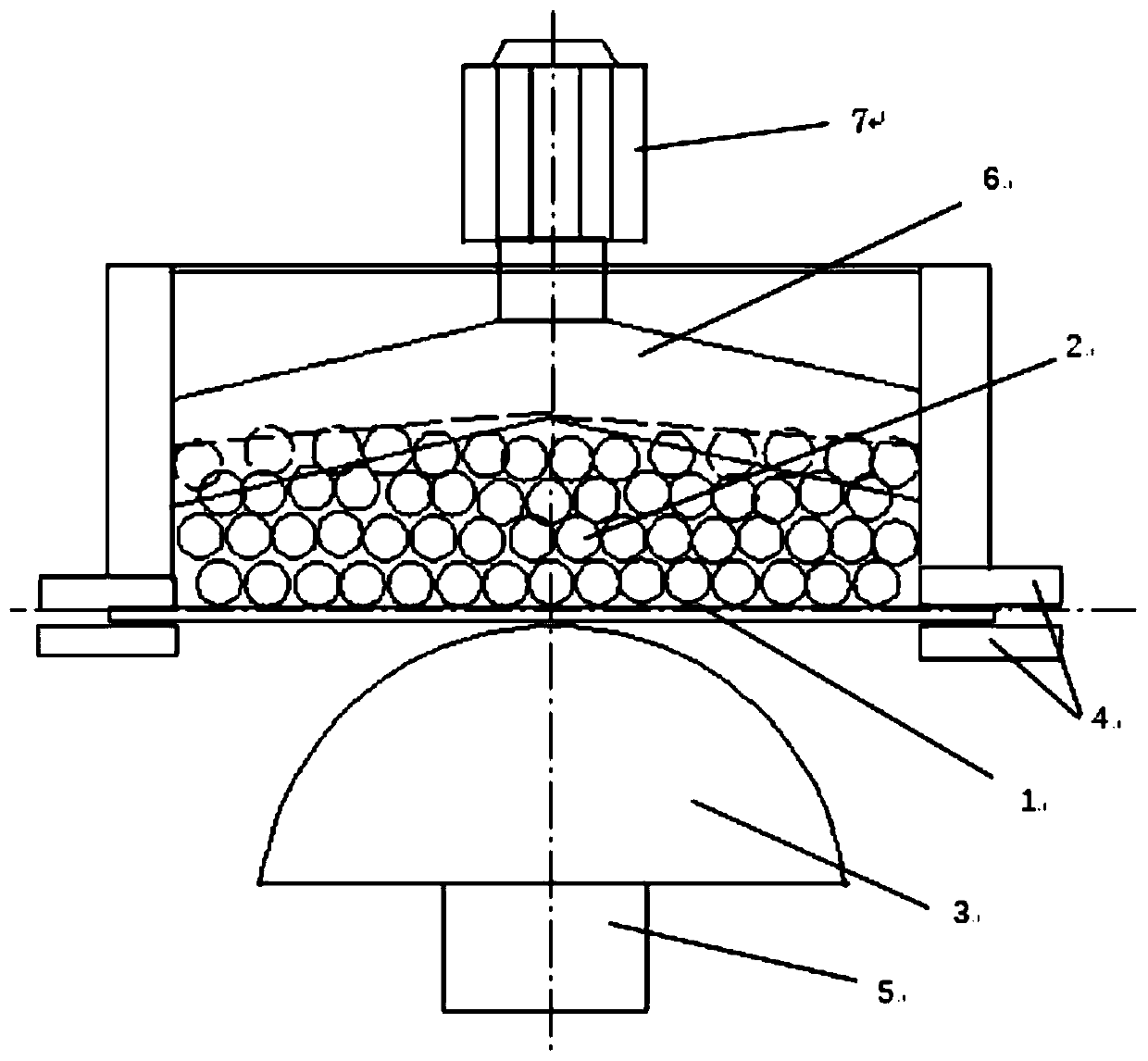

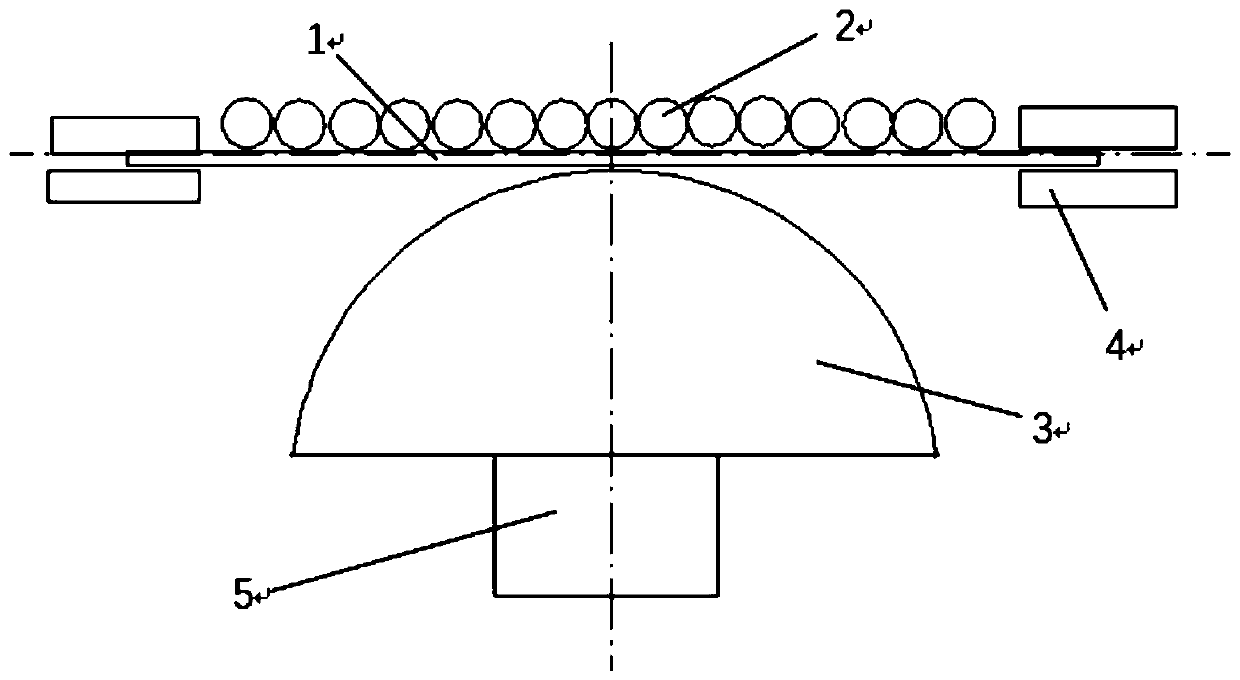

[0040] Through the above theoretical analysis and experimental verification, such as Figures 2 to 6 As shown, the present invention provides a kind of cluster steel ball half mold uniform spinning titanium alloy plate forming process, the corresponding example is provided below in conjunction with specific material requirements, and it comprises the following steps:

[0041] S1. Intercept titanium alloy plate blank 1: the titanium alloy plate blank 1 is a deformed titanium alloy plate TA2 with a thickness of 1mm, and the shape and size of the formed product are calculated to be 100×100mm 2

[0042] S2. Open the mold: use the electromagnet to attract a large number of steel balls 2 needed in the spinning machine, and at the same time move the hydraulic rod 5 down to the lowest position, and the spinning die 3 fixed on the upper end of the hydraulic rod 5 will move down to the Minimum, the total volume of the steel ball should be the volume of the spinning machine cavity minus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com