A method and device for forming by internal pressure expansion and reverse deep drawing

A technology of reverse deep drawing and bulging, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc. It can solve problems such as high risk, difficult to guarantee weld quality, complicated calculation and blanking, etc., and achieve low pressure requirements , energy saving, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

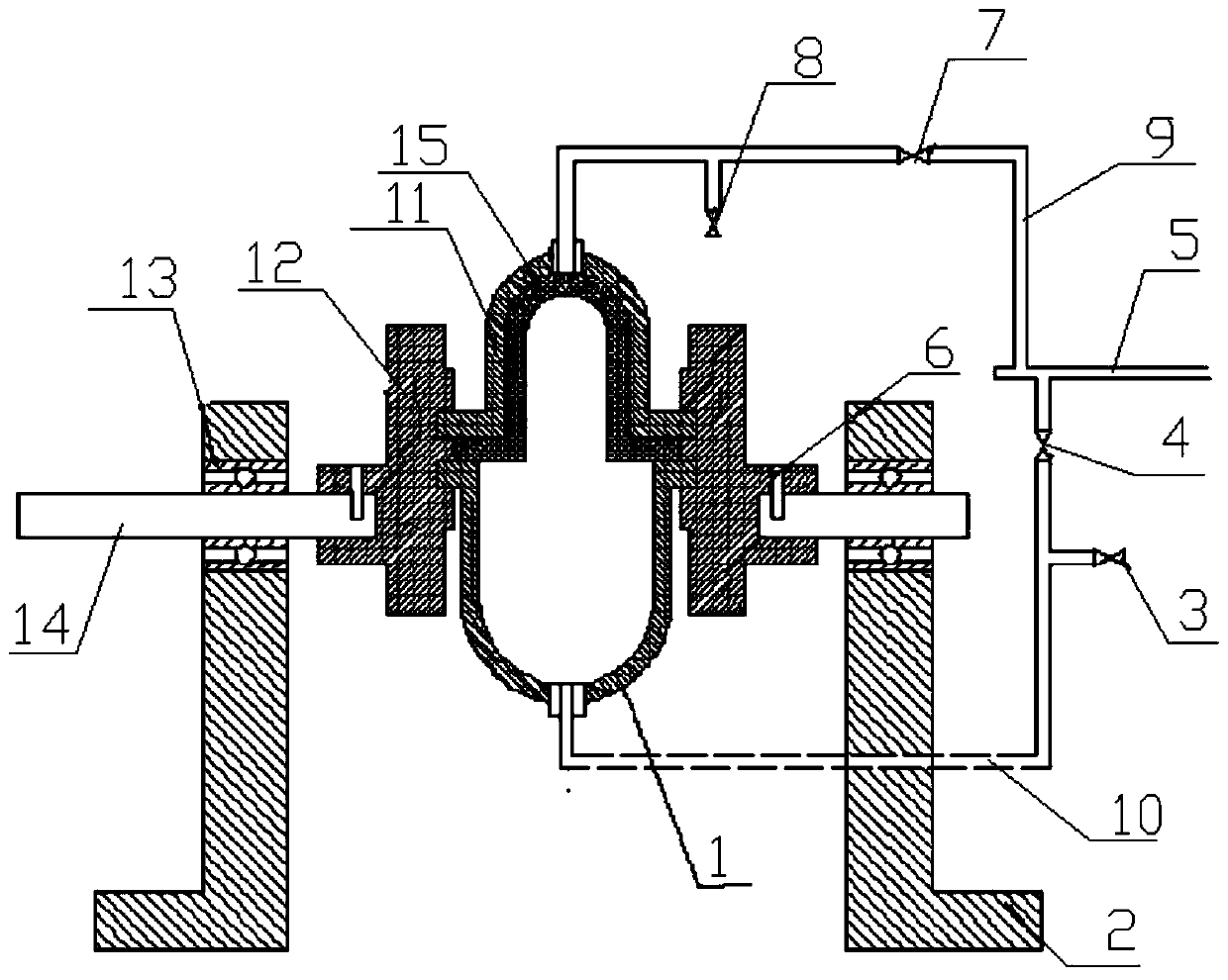

[0021] The present invention is an internal compression expansion type and reverse deep drawing forming device, such as figure 1 As shown, the base 2 comprising a built-in cavity has a shaft 14 passing through the same position on the opposite side of the base 2, and one end of each shaft 14 outside the base 2 is connected to the drive mechanism, and the other end of each shaft 14 is The frame 12 is connected by the pin 6, so that the shaft 14 can drive the frame 12 to rotate together, and an upper mold 11 is connected between the two frames 12, and a lower mold 1 is connected between the two frames 12, and the upper mold 11. A hole is respectively opened on the top of the lower mold 1, and the upper mold 11 and the lower mold 1 are respectively connected to the same fluid medium pressure transmission system through the holes, and the fluid m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com