Powder forming machine

A technology of powder molding machine and molding machine, which is applied in the direction of material molding presses, presses, manufacturing tools, etc., which can solve the problem of affecting the popularization and application and use value of powder molding machines, the inconsistency of the upper and lower densities of pressed products, and the inability to satisfy users and other problems, to achieve the effect of excellent processing quality, uniform density and uniform force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

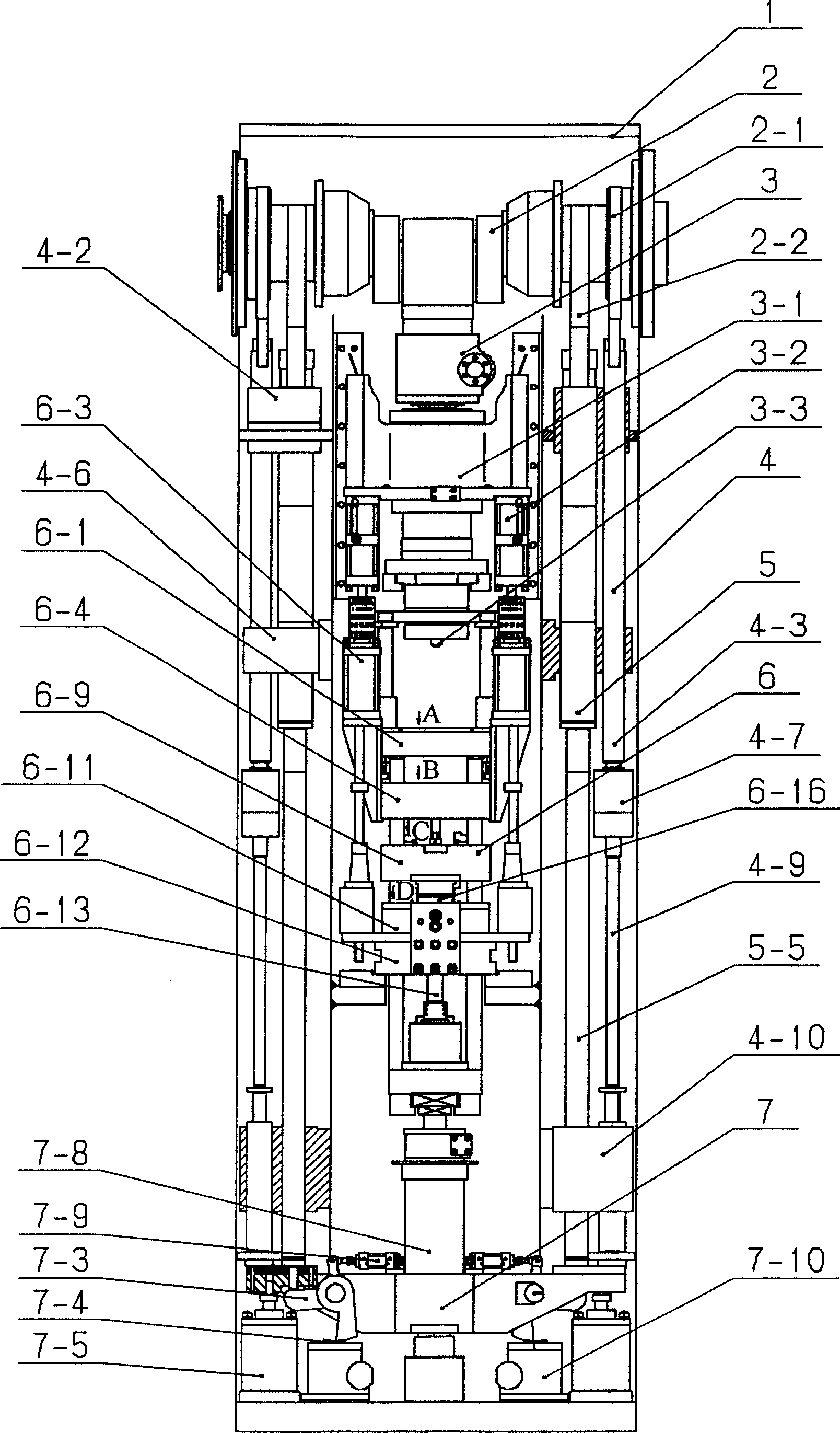

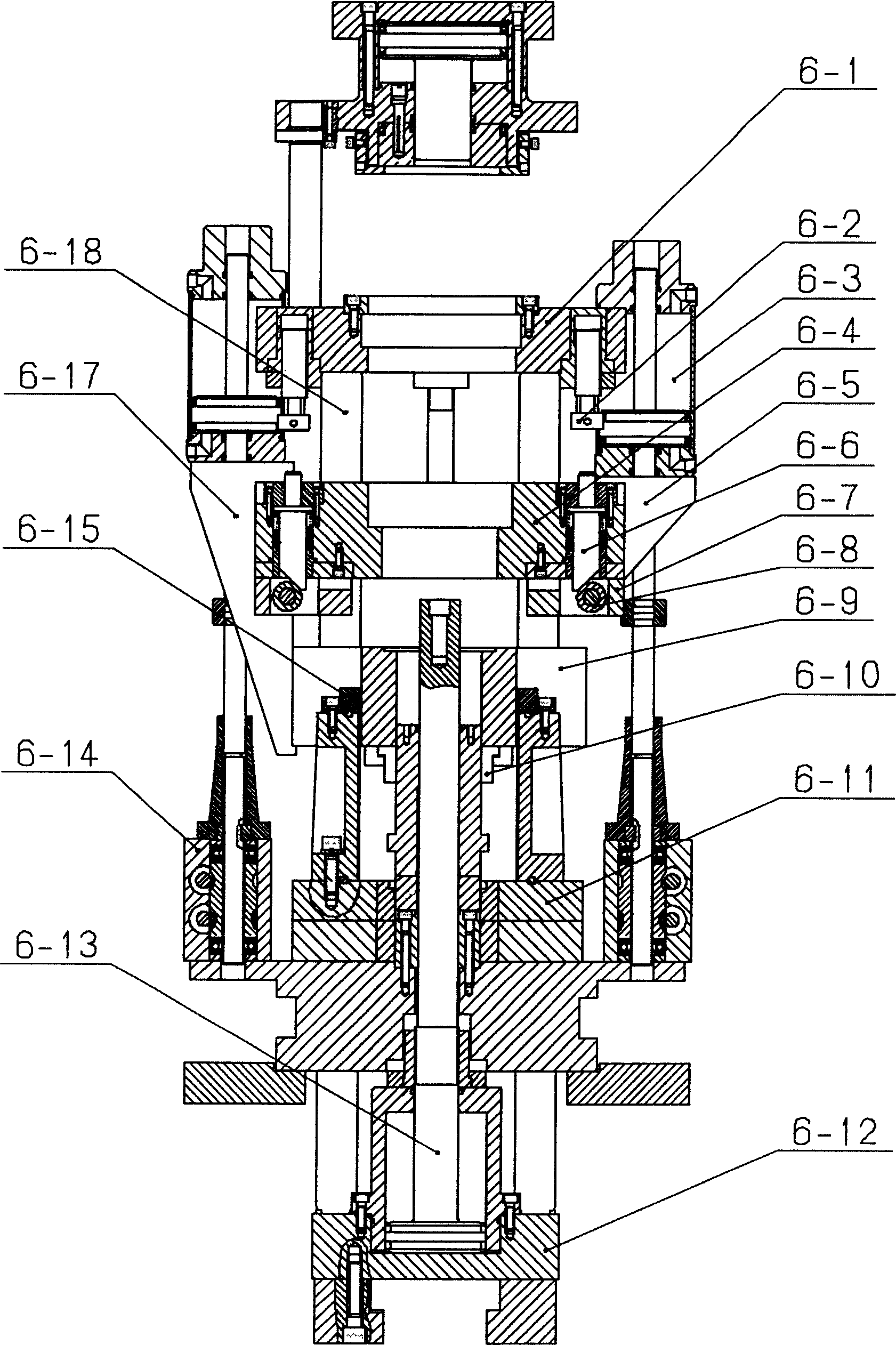

[0019] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

[0020] Crankshaft 2 is installed on the horizontal position above the frame 1, symmetrical, two pairs of ejection cams 2-2 and pressurization cams 2-1 are installed on both sides of crankshaft 2, and pressurization cam 2-1 cooperates with pressure rod 4 to eject the mold Cam 2-2 cooperates with ejection lever 5.

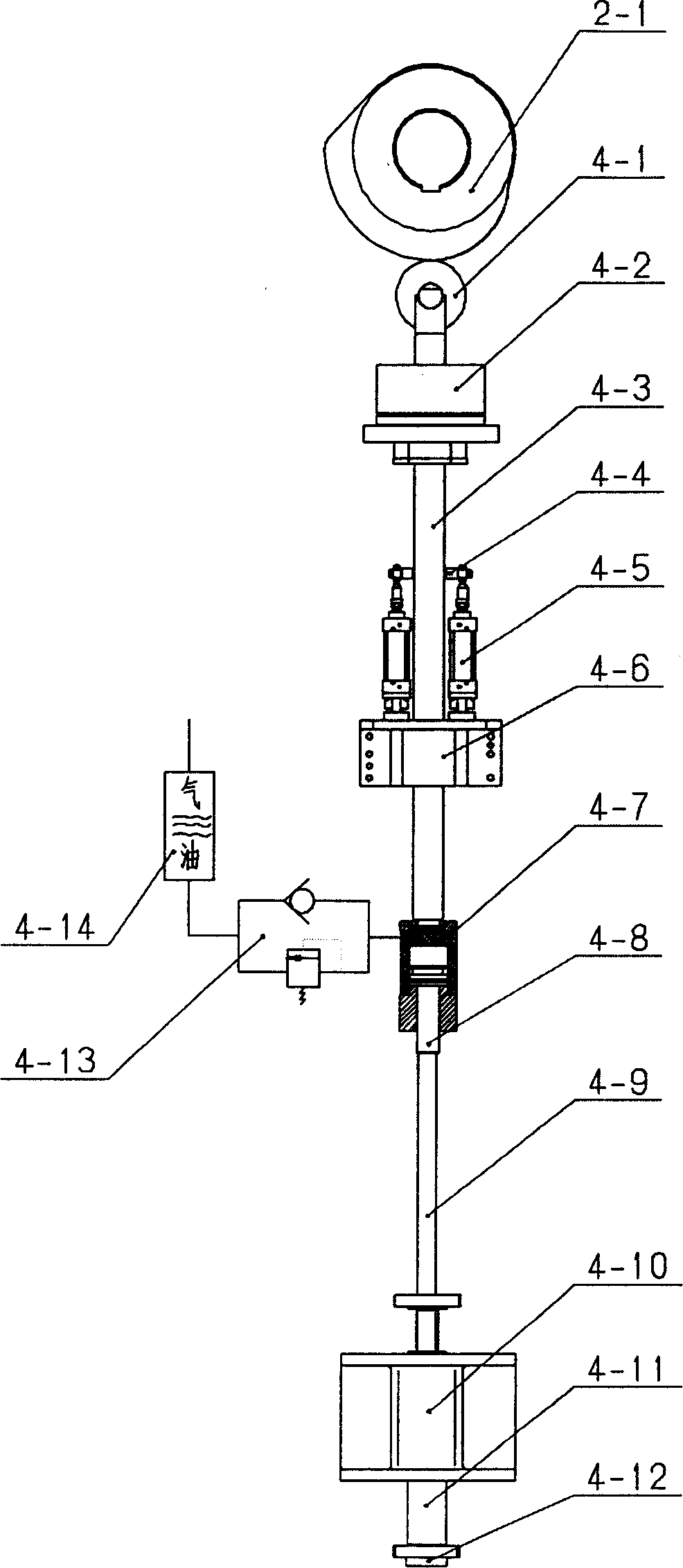

[0021] The pressure rod 4 is movably connected into one by the upper pressure rod 4-3 and the lower pressure rod 4-9 through the oil cylinder body 4-7 and the piston rod 4-8, and the oil cylinder body 4-7 is connected with the pressure regulating valve 4-13, gas-liquid Conversion cylinder 4-14 connection. Connect a roller 4-1 with pivot pin at the top of pressure bar 4, and the upper end and the middle part of upper pressure bar 4-3 slide and are equipped with upper axle seat 4-2, lower axle seat 4-6. Respectively install a cylinder 4-5 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com