Full-automatic mechanical hammering type meat stuffing preparation machine

A mechanical hammer and fully automatic technology, which is applied in the fields of meat processing, slaughtering, food science, etc., can solve the problems of poor taste, unsafe hygiene, inconvenient production of fibrous meat stuffing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

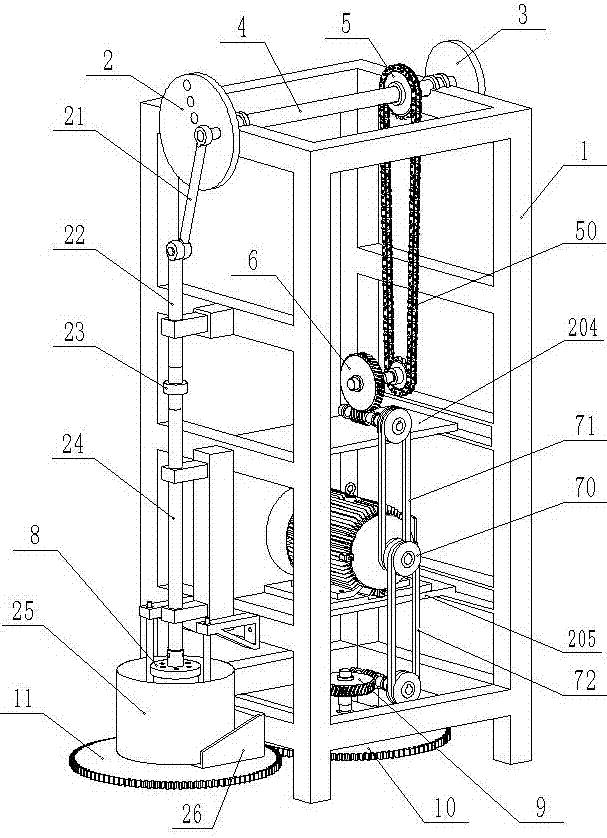

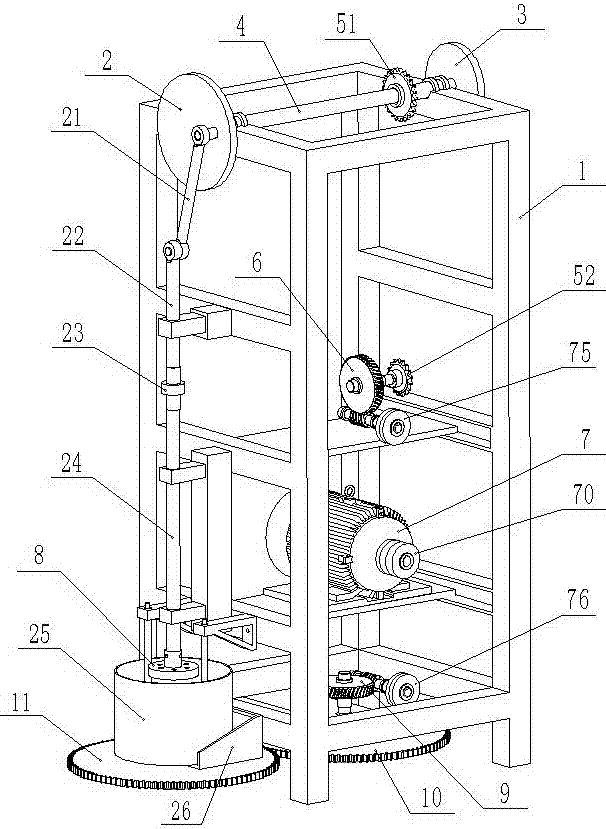

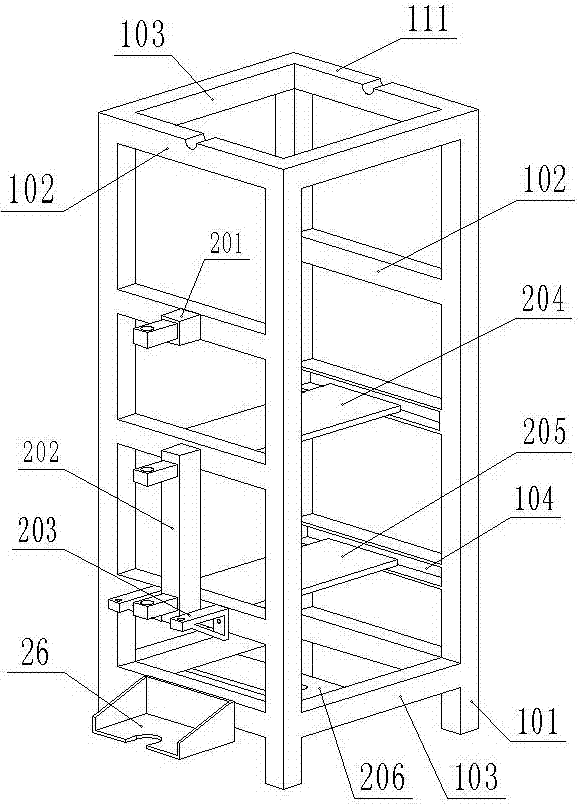

[0046] attached figure 1 As an embodiment of the present invention, combined with figure 1 to attach Figure 24 This embodiment is specifically described, including a frame body 1, a rotating shaft 4, a crank turntable 2, a flywheel 3, a chain transmission mechanism 5, an intermediate worm gear mechanism 6, an electric motor 7, a beating device 8, a base worm gear mechanism 9, a driving gear 10, and a driven Gear 11, rotating cylinder 25, overload nut 23, main drive and stirring device, beating device 8 is arranged on the left side of frame body 1, and described frame body 1 is set to rectangular rod frame body, is provided with at the top of frame body 1 The rotating shaft 4 is provided with a crank turntable 2 fixedly installed at the leftmost end of the rotating shaft 4, the crank turntable 2 is coaxial with the rotating shaft 4, and a flywheel 3 is fixedly installed at the rightmost end of the rotating shaft 4, and the flywheel 3 is used for balancing and adjusting the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com