A method for regulating the crystallization of α-olefin homopolymer by processing conditions

A technology of olefin homopolymer and processing conditions, applied in the field of polymer crystallization, can solve the problems of low crystallization temperature and unfavorable processing and molding, and achieve the effect of shortening crystallization time and improving processing and molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 The method for preparing α-olefin homopolymers of different crystal forms by regulating and controlling processing conditions, comprising the following steps:

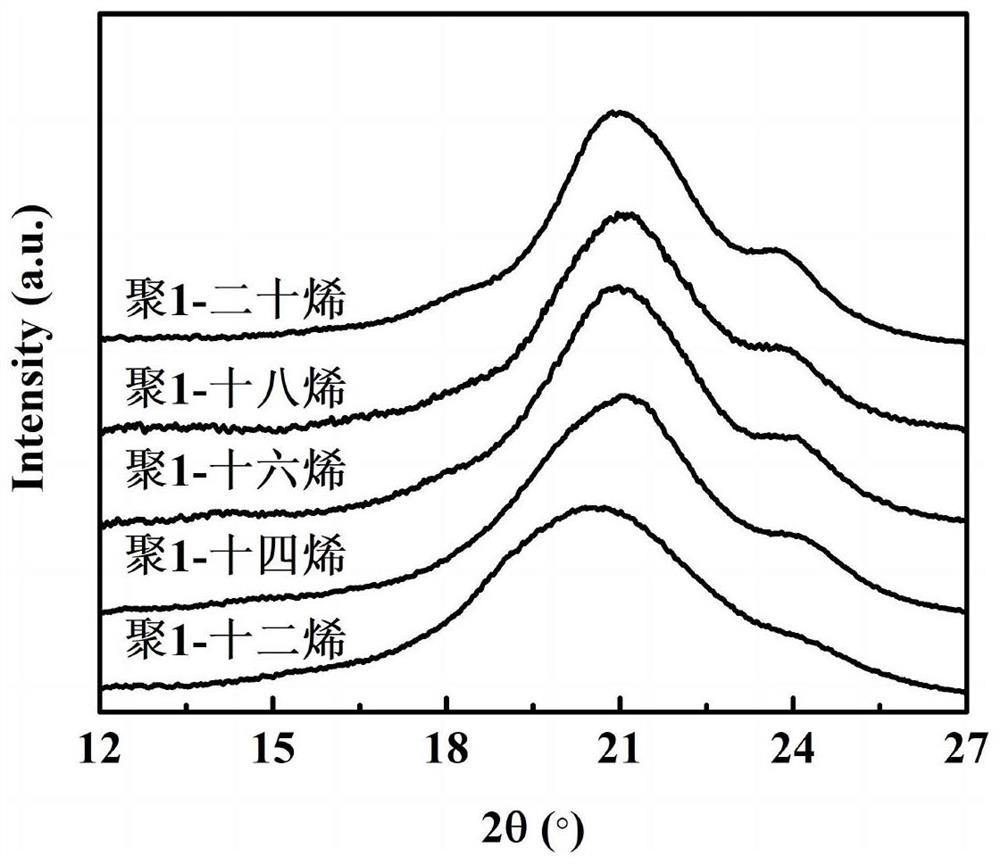

[0036] Long chain alpha-olefin homopolymers were thermally treated using a Linkam hot stage. The temperature was raised to 160°C at 10°C / min and kept for 10min, and then cooled to -30°C at 10°C / min, and the Type II crystal was obtained by crystallization. The samples obtained by cooling and crystallization were characterized by WAXD, such as figure 1 shown. The sample has obvious diffraction signals at 2θ=21° and 23.7°, indicating that Type II crystal form is formed by cooling at 10°C / min.

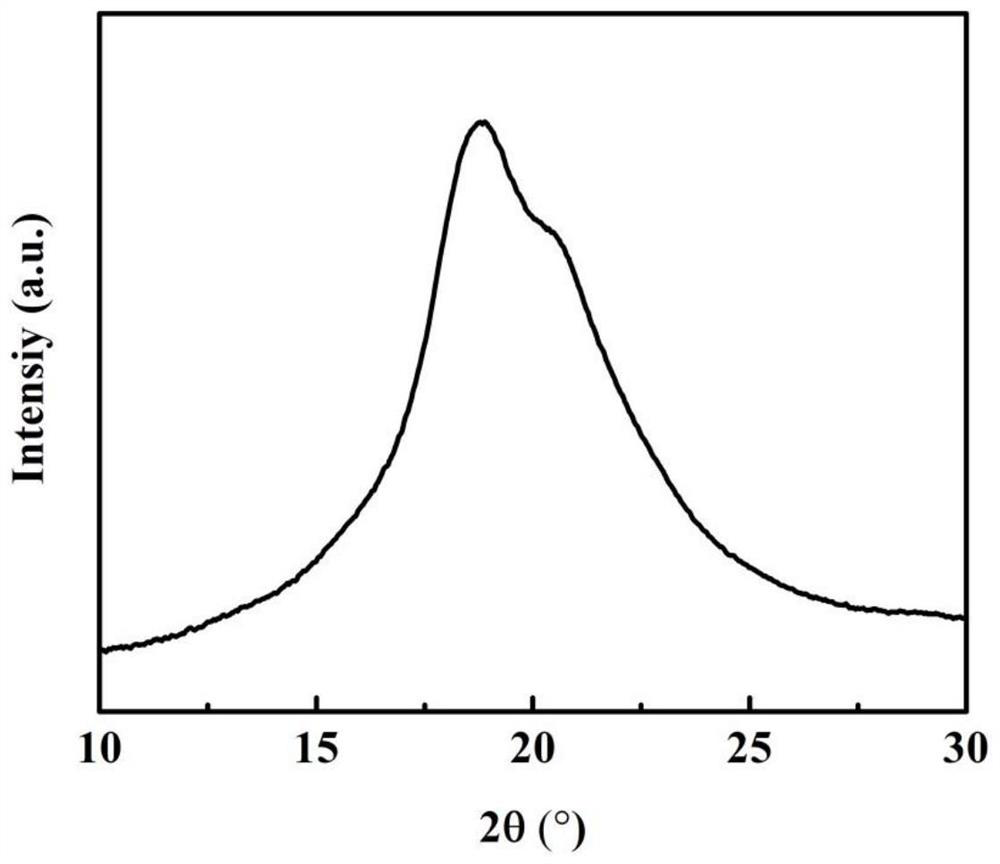

[0037] The poly-1-tetradecene sample was heat-treated with a Linkam hot stage, heated to 160 °C at 10 °C / min and held for 10 min, then quenched with liquid nitrogen for 30 s and returned to room temperature. The samples obtained by cooling and crystallization were characterized by WAXD, such as figure 2 sho...

Embodiment 2

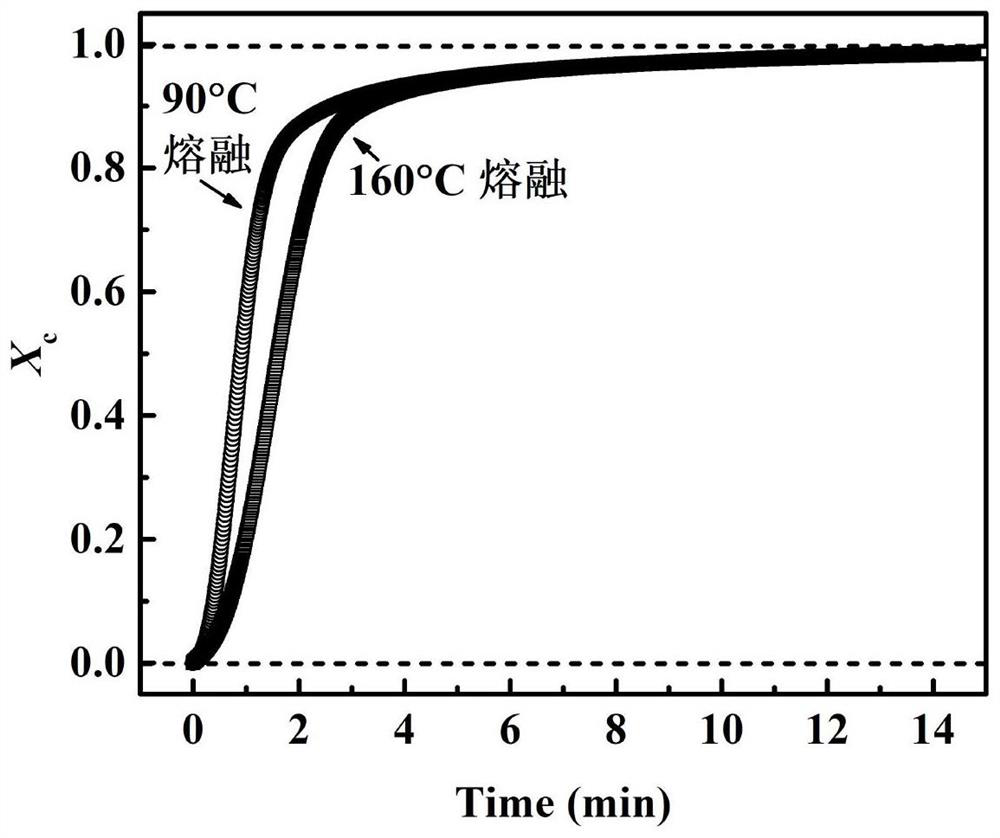

[0039] Testing was performed using a DSC Q2000 (TAInstrument). Weigh 5 mg of poly-1-hexadecene sample, put it into a crucible, heat it up to 160 °C at 10 °C / min and keep it for 10 minutes, then cool it down to -30 °C at 10 °C / min and keep it for 2 minutes to obtain a Type II crystal sample; Then, the temperature was raised to 90°C and 160°C at 5°C / min, maintained for 10 minutes, and then cooled to 44°C at 10°C / min, and isothermally crystallized to complete crystallization. Relative crystallinity X during isothermal crystallization at 44°C for samples after melting at 90°C and 160°C c Change with time image 3 shown.

[0040] Relative crystallinity X c Calculated by the following formula:

[0041]

Embodiment 3

[0044] Testing was performed using a DSC Q2000 (TA Instrument). Weigh 5 mg of poly-1-octadecene sample, put it into a crucible, heat it up to 160 °C at 10 °C / min and keep it for 10 minutes, then cool it down to -30 °C at 10 °C / min and keep it for 2 minutes to obtain a Type II crystal sample. , and then heated to 110°C and 160°C at 5°C / min respectively and kept for 180min, then cooled to 52°C at 10°C / min and isothermally crystallized to complete crystallization. Relative crystallinity X of samples melted at 110°C and 160°C during isothermal crystallization at 52°C c Change with time Figure 4 shown. from Figure 4 It can be seen that under the same isothermal crystallization temperature conditions, the time for complete crystallization when the melting temperature is 110 °C is shorter than that when the melting temperature is 160 °C, which shows that the method of reducing the melting temperature can effectively shorten the crystallization time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com