Establishment method of foam system microscopic model

A foam system and microscopic model technology, applied in the fields of instrumentation, computational theoretical chemistry, informatics, etc., can solve problems such as the inability to characterize the evolution process of a circular foam system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

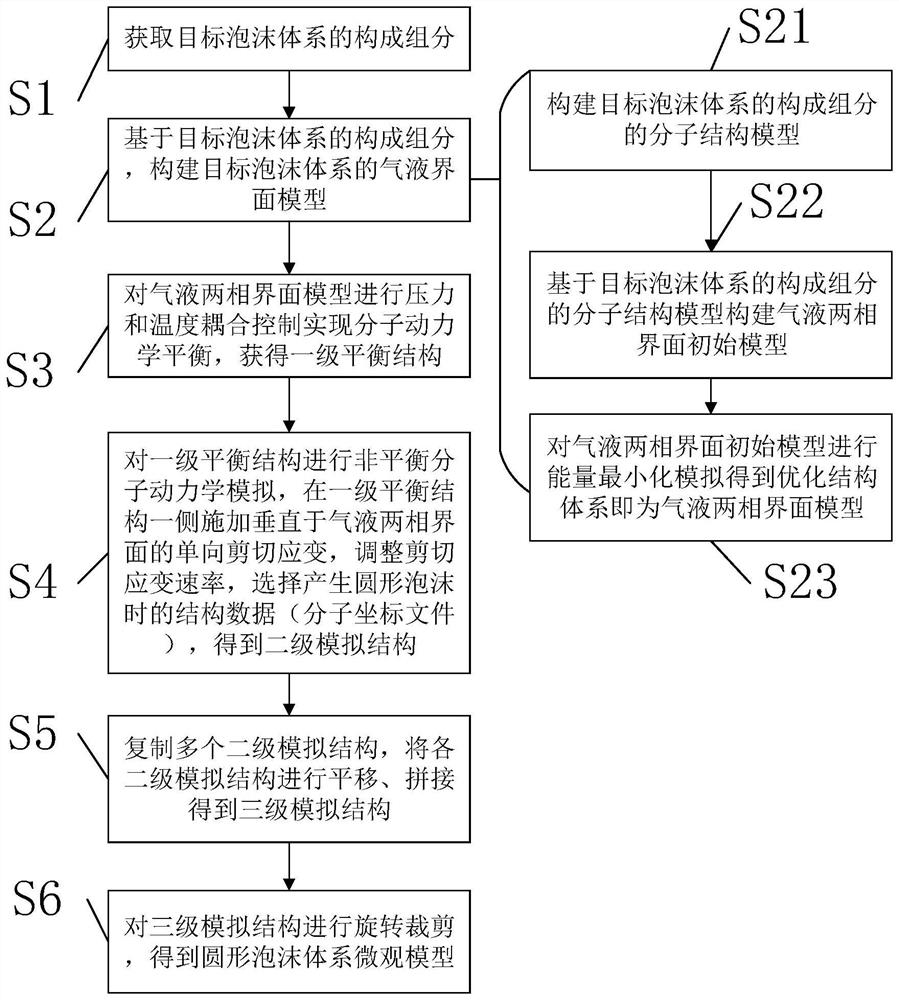

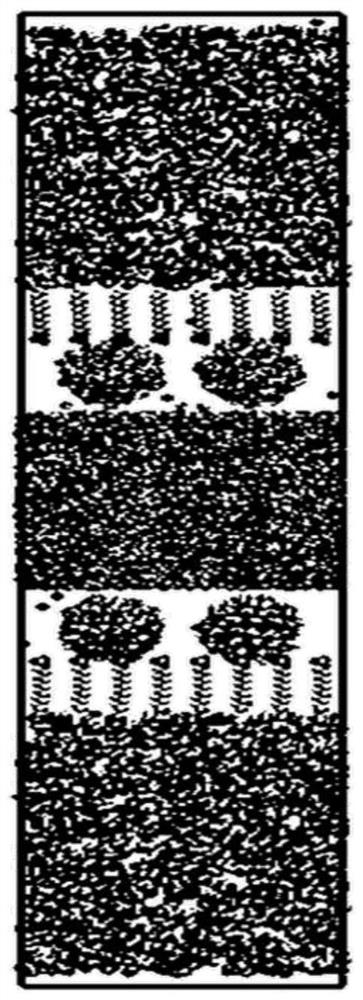

[0084] The present embodiment provides a method for establishing a microscopic model of a foam system, the method comprising:

[0085] 1. Obtain the constituent components of the target foam system; specifically:

[0086] The constituent components of the target foam system include carbon dioxide gas, water, sodium dodecyl sulfate (SDS) foaming agent, and silica nanoparticle foam stabilizer.

[0087] 2. Use Materials Studio software to build CO 2 Molecular structure model, water molecular structure model, sodium lauryl sulfate molecular structure model, silica nanoparticle molecular structure model; specifically:

[0088] Build CO with Materials Studio software 2 Molecular structure, water molecular structure, sodium lauryl sulfate molecular structure, silica nanoparticle molecular structure, convert the obtained molecular structure coordinates into the input coordinate files required by molecular simulation software, and complete CO 2 Molecular structure model, water molec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com