Method used for calculating cutting process strain rate based on grid flow difference

A cutting process and strain rate technology, used in the analysis of materials, testing machinability, instruments, etc., can solve problems such as limiting the understanding of the cutting process and high cutting speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

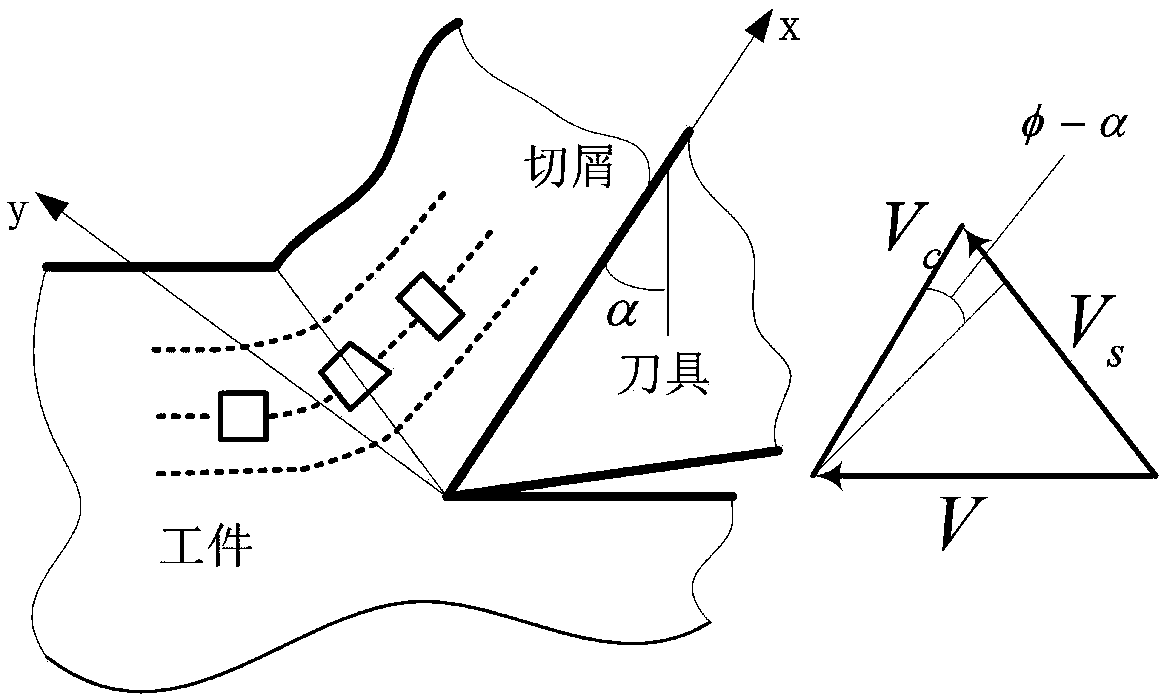

[0055] Such as figure 1 As shown, the grid of nanoscale size is processed by femtosecond laser, the angle of tool rake angle α and the angle of shear angle φ are measured, and the cutting speed V is measured;

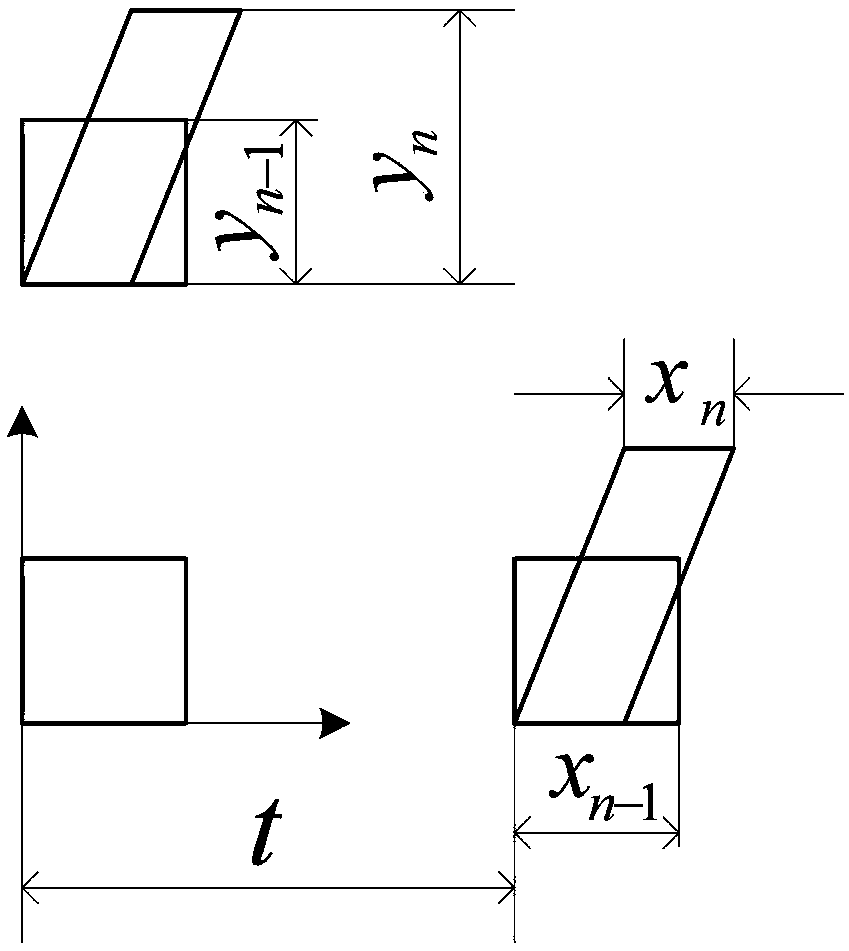

[0056] Such as figure 2 As shown, the grid in a certain area starts from the initial slip line, and after a period of time t slips, it crosses the shear plane and deforms at the same time. After measuring the lengths of xn-1 and xn, that is, measuring the lengths of two adjacent grids The length of the grid in the x direction, then the deformation of the grid in the x direction is:

[0057]

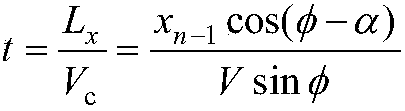

[0058] The elapsed time t is:

[0059]

[0060] Combining the two formulas (1) and (2), the strain rate distribution along the rake face direction is obtained as

[0061]

[0062] Similarly, the shear strain rate along the shear plane direction can be obtained

[0063]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com