Improved powder injection molding shot, product manufactured therefrom, and product manufacturing method

An injection molding and powder technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of reducing the quality of injection molding products, increasing the viscosity of injection materials, and decreasing fluidity, so as to maintain strength and quality, reduce difficulty, The effect of increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

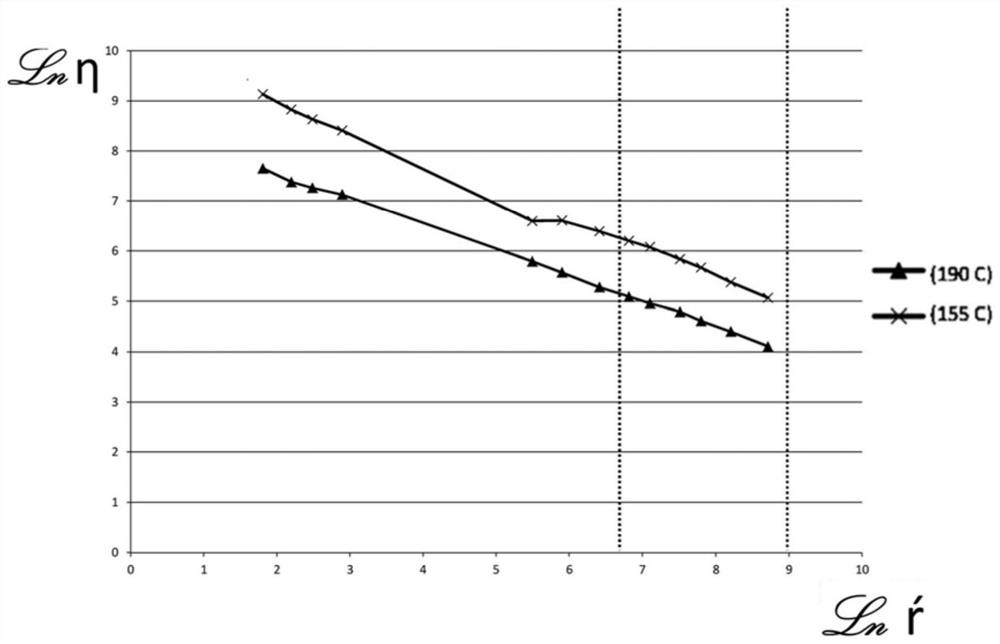

[0040] Maleic anhydride modified low-density polyethylene, maleic anhydride modified low-density polyethylene, 18302N, the density is 0.912g / cm 3 ), the density is 0.955g / cm 3 high-density polyethylene, polyoxymethylene, stearic acid, paraffin wax and microcrystalline wax at a weight ratio of 2:1, and polyurethane (purchased from Asahi Denka Industry Co., Ltd., model UH-462), with a ratio of about 1: 20:7:2:30:11 weight ratio, uniformly mixed at about 180°C for about 120 minutes to form a binder, and then mixed the above binder with a volume ratio of binder: metal powder of 40:60 Metal powder (Mitsubishi 17-4PH), can obtain the shot material of example 1 of the present invention. The relationship between the viscosity and the shear strain rate of the injection material of Example 1 at 155°C and 190°C is as follows image 3 shown.

example 2

[0042] Maleic anhydride modified low-density polyethylene, maleic anhydride modified low-density polyethylene, 18302N, the density is 0.912g / cm 3 ), the density is 0.955g / cm 3 High-density polyethylene, polyoxymethylene, stearic acid, paraffin wax, and carnauba wax, in a weight ratio of about 1:20:7:2:20:11, were uniformly mixed at about 180°C for about 120 minutes to form a bond agent, and then mix the above-mentioned binder and metal powder (Mitsubishi 17-4PH) at a volume ratio of binder: metal powder of 40:60 to obtain the shot of Example 2 of the present invention. The relationship between the viscosity and the shear strain rate of the shot material of Example 2 at 155°C and 190°C is as follows Figure 4 shown.

example 3

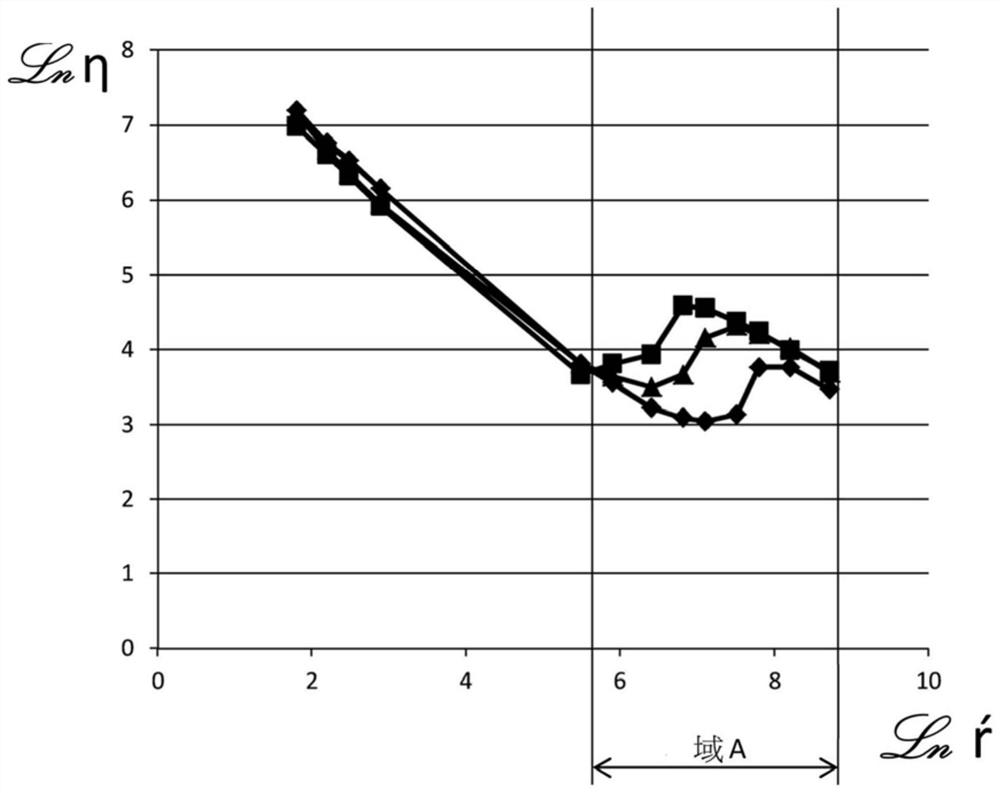

[0044] Maleic anhydride modified low-density polyethylene, maleic anhydride modified low-density polyethylene, 18302N, the density is 0.912g / cm 3 ), the density is 0.955g / cm 3 High-density polyethylene, polyoxymethylene, stearic acid, paraffin wax and microcrystalline wax with a weight ratio of 2:1, and diallyl phthalate prepolymer (purchased from Japan Dasao Co., Ltd., model DAISO DAP-A), with a weight ratio of about 1:10:3:1:15:6, uniformly mixed at about 180°C for about 120 minutes to form a binder, and then use a binder:metal powder ratio of 40:60 The volume ratio of the above binder and metal powder (Mitsubishi 17-4PH) is mixed to obtain the shot material of Example 3 of the present invention. The relationship between the viscosity and the shear strain rate of the shot material of Example 3 at 155°C and 190°C is as follows Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com