Method for determining grain size in equal channel angular pressing technology

A technology of equal angular extrusion and grain size, which is applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of improving the predictive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

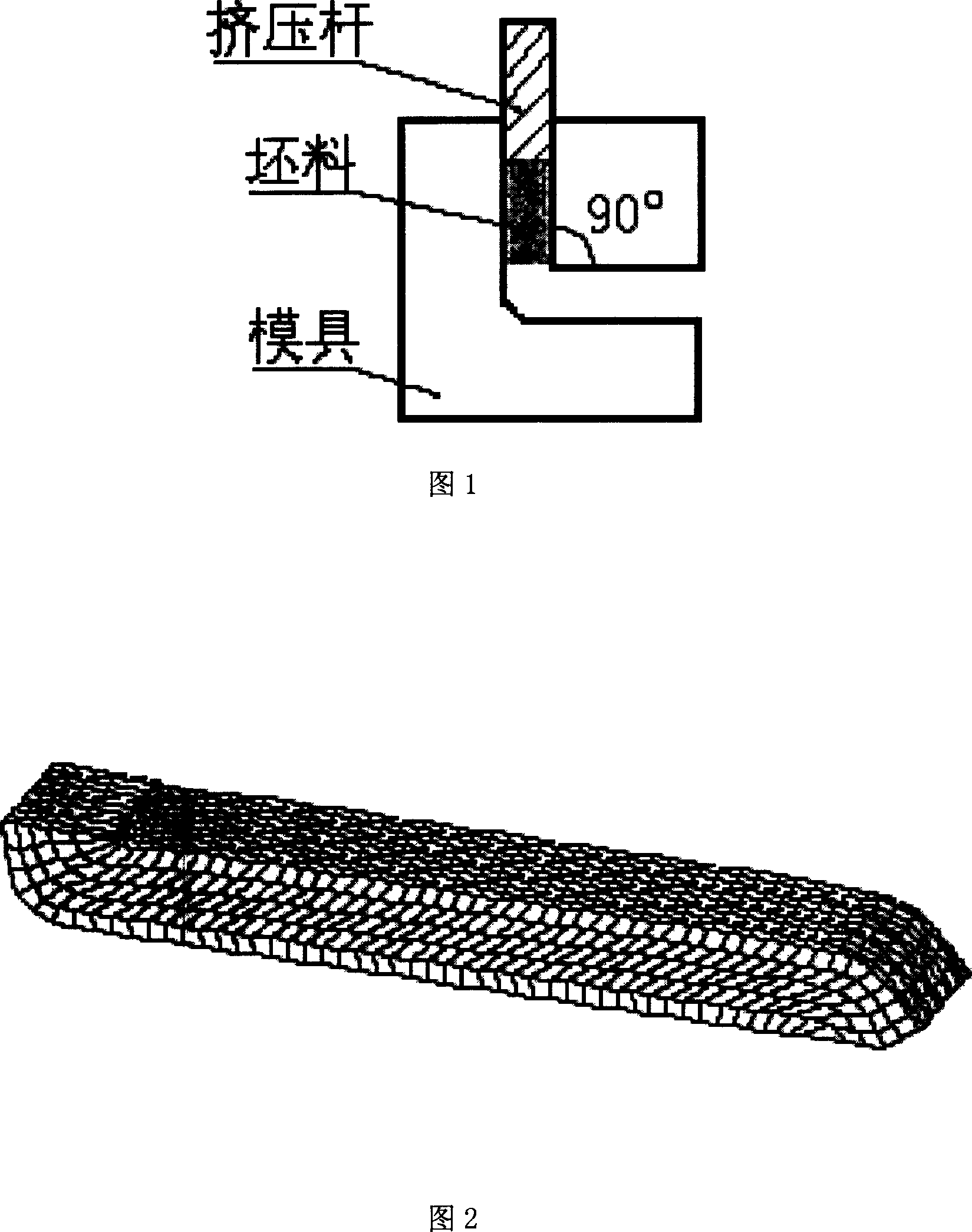

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

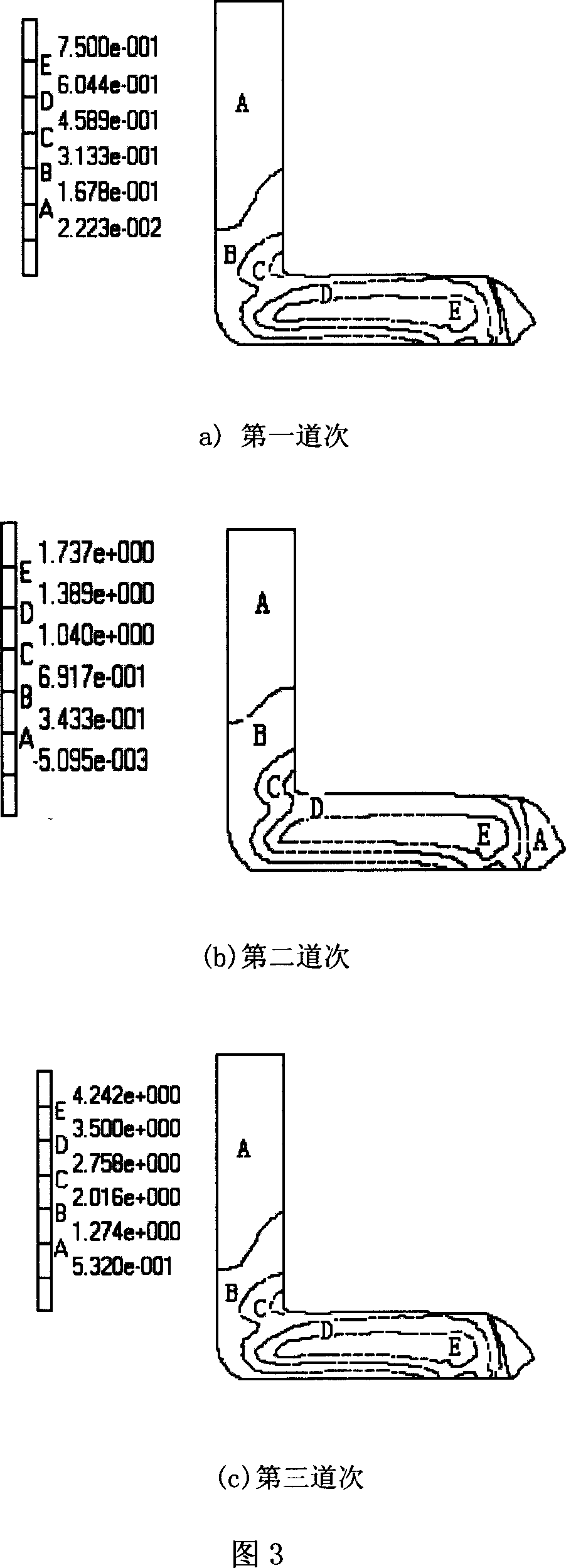

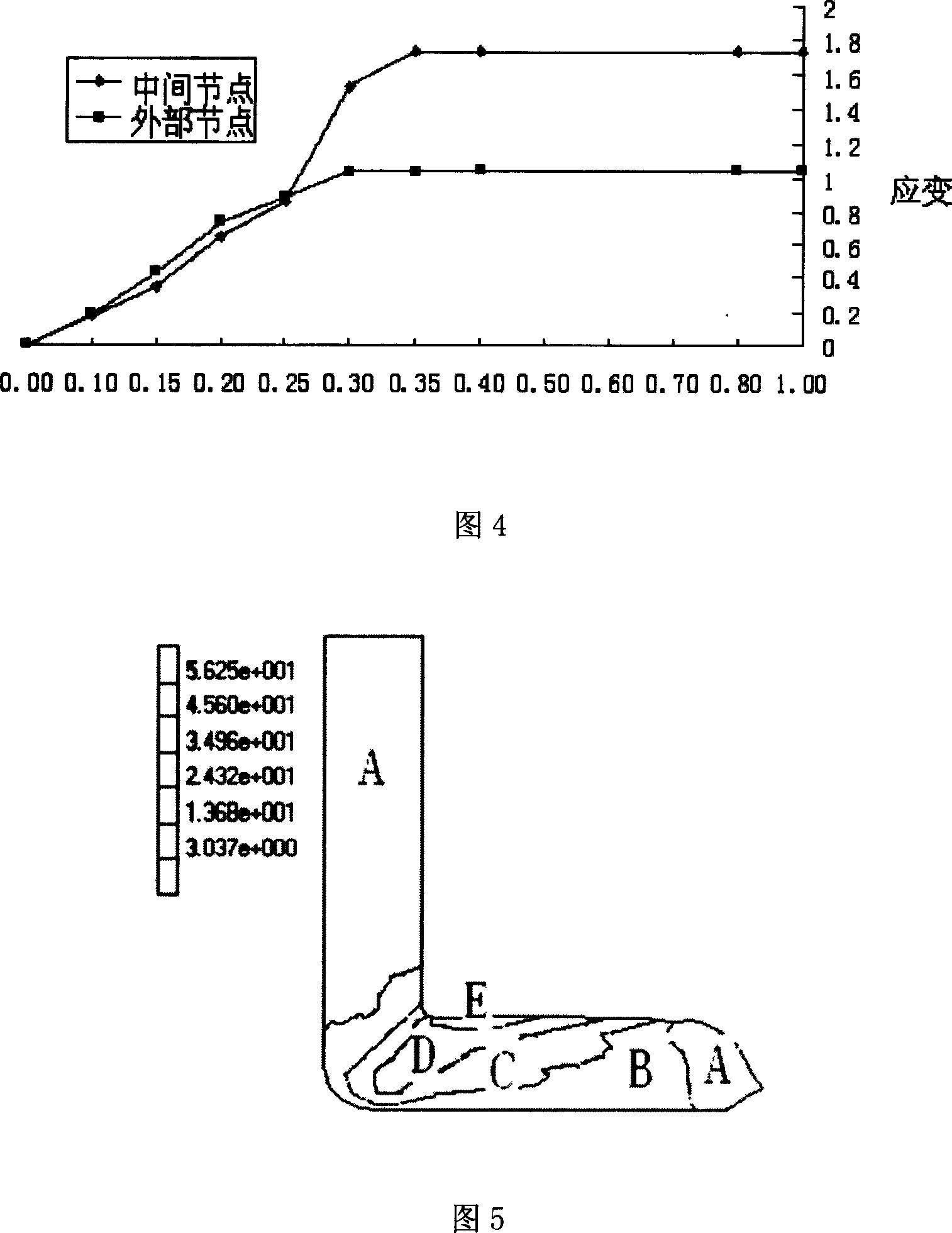

[0022] In the implementation of the present invention, the metal material subjected to extrusion deformation is first discretized by finite element, divided into several finite element units, each unit is given relevant material characteristic parameters, and the calculation process is divided into several time steps. In each time step, the central difference algorithm in the conventional dynamic explicit finite element method is used to calculate the displacement of each unit node in the extrusion deformation, and the strain at each position is calculated through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com