Sandwich energy-absorbing device

An energy-absorbing device and core-sandwich technology, applied in the field of energy-absorbing, can solve the problems of unsatisfactory energy-absorbing effect, inability to satisfy structural strength, stiffness, vibration resistance, impact resistance energy absorption performance, poor structural vibration resistance, etc. Achieve the effect of improving energy absorption capacity, improving anti-vibration capacity, and high specific strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

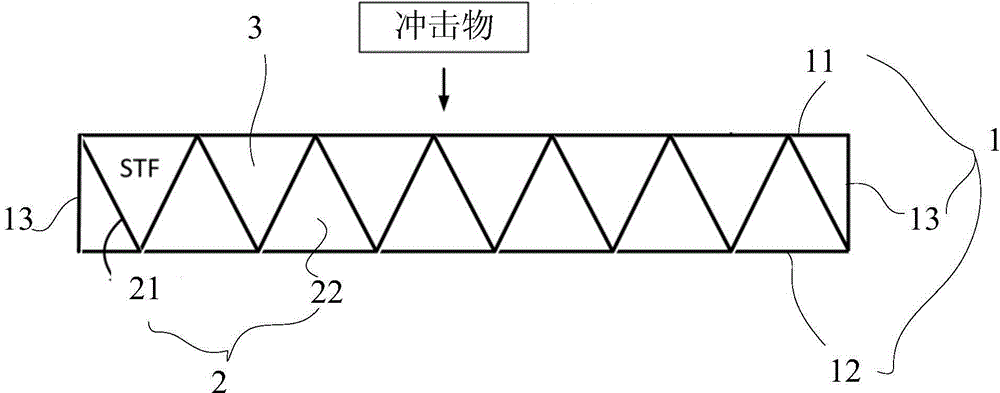

[0027] Such as figure 1 As shown, the embodiment of the present invention provides a sandwich energy-absorbing device, which includes a packaging panel 1 and a core layer 2 sealed in a closed space inside the packaging panel 1. The core layer 2 is composed of a core material 21 and filled in the core. material 21 and / or filled between the core material 21 and the closed space inside the packaging panel 1 formed by shear thickening fluid material 22; wherein the packaging panel 1 includes an upper panel 11, a lower panel 12, a side panel 13, a core panel The layer 2 is filled in the closed space formed by the upper panel 11, the lower panel 12, and the side panels 13. The core layer 2 includes a core material 21 and is filled between the core materials 21 and / or between the core material 21 and the Shear thickening fluid material 22 between the enclosed spaces.

[0028] The core material 21 in the present invention mainly forms a support skeleton for the core plate layer 2, an...

Embodiment 2

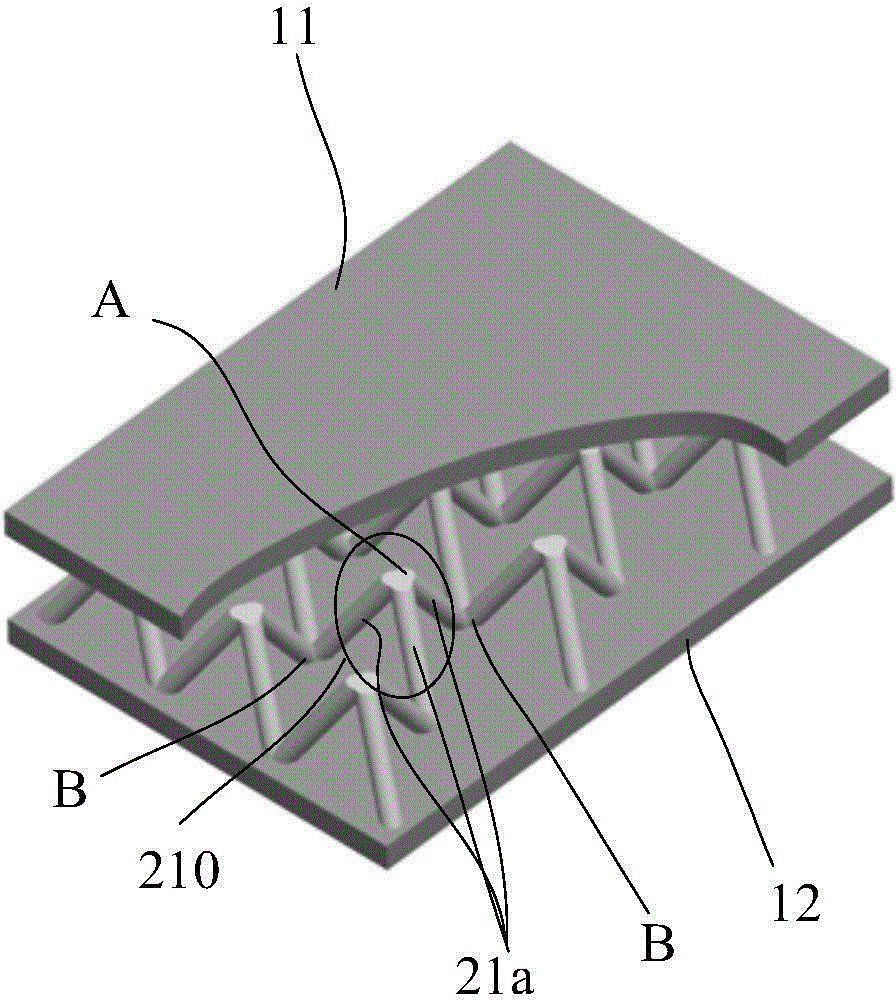

[0033] see figure 2 , the core material 21 is connected to each other by a plurality of first node units 210 to form a network; each first node unit 210 includes more than three (three in this embodiment, see figure 2 ) is a core material rod 21a arranged in a spatial shape, one end of the core material rod 21a is connected to the same node (the first node A), and the other end of the core material rod is connected to the node (the first node A) respectively. On a different node (the second node B) that is adjacent and opposite in direction; the node above (see figure 2 The first node A) in is connected to the upper panel 11, and the lower node (see figure 2 The second node B) in is connected to the lower panel 12 .

Embodiment 3

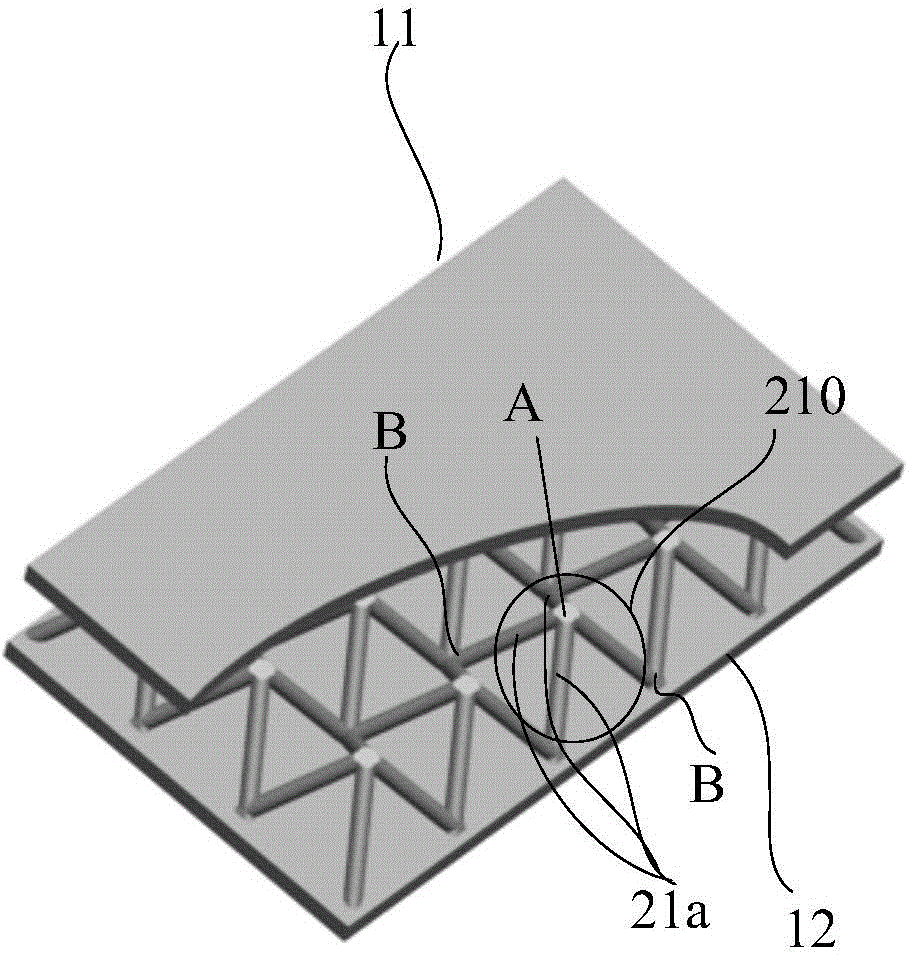

[0035] see image 3 The only difference between this embodiment and the second embodiment is that each first node unit 210 includes four core material rods 21a arranged in a spatial shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com