Vehicle bumper

A technology for bumpers and vehicles, applied in the field of vehicle bumpers, can solve the problems of low safety, poor buffering and energy-absorbing effect of bumpers, etc., and achieve the effects of fast response speed, superior buffering protection performance, and high energy-absorbing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

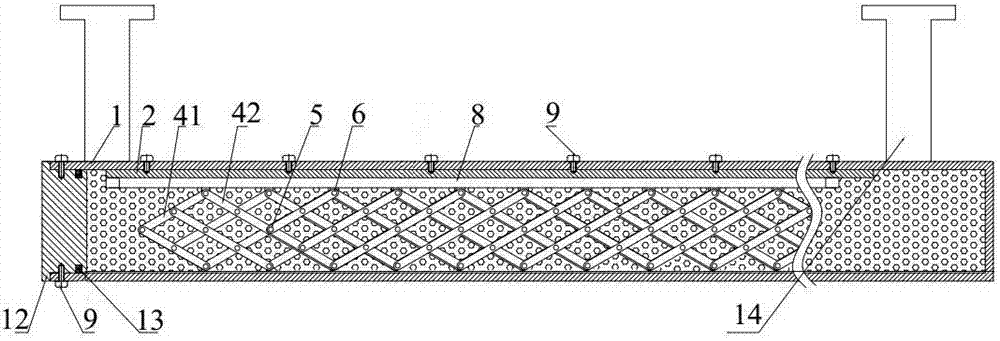

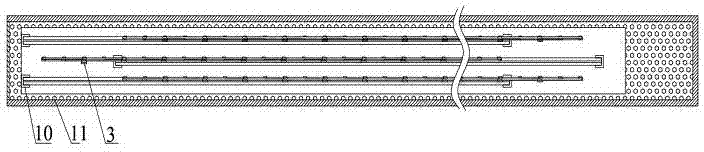

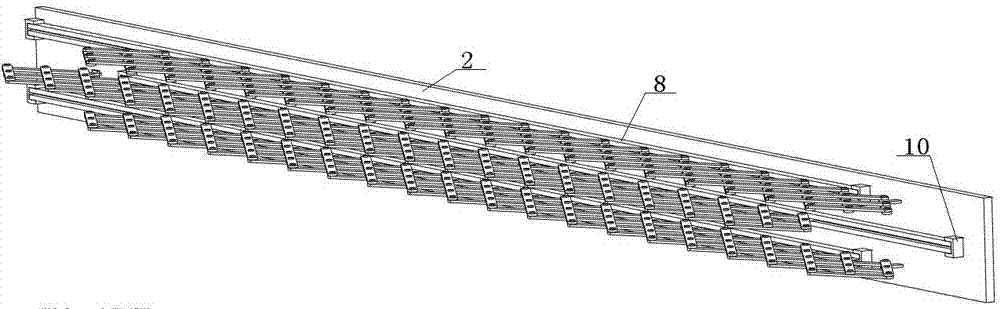

[0026] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a vehicle bumper includes a packaging layer 1, a mounting plate 2, a fixing ring 3, a forward rod 41, a reverse rod 42, a short shaft 5, a long shaft 6, a T-shaped slider 7, a guide rail 8, a fastening Screw 9, cover 10, STF11, end cap 12, sealing ring 13, anti-collision beam support frame 14 and shear synergistic device, said STF11 is formed by stirring and mixing silicon dioxide nanoparticles and PEG200, and said The micropore diameter of the silicon nanomaterial is 180nm; the encapsulation layer 1 is a metal member with an unclosed end and a cavity inside, and the interior of the encapsulation layer 1 is filled with STF11; the end cap 12 is set inside the unenclosed end of the encapsulation layer 1 The anti-collision beam support frame 14 is located on the outer surface of the packaging layer 1; the outer end surface of the mounting plate 2 is connected with the inner surface of the packaging layer 1 ...

Embodiment 2

[0035] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a vehicle bumper includes a packaging layer 1, a mounting plate 2, a fixing ring 3, a forward rod 41, a reverse rod 42, a short shaft 5, a long shaft 6, a T-shaped slider 7, a guide rail 8, a fastening Screw 9, cover 10, STF11, end cap 12, sealing ring 13, anti-collision beam support frame 14 and shear synergistic device, said STF11 is formed by stirring and mixing silicon dioxide nanoparticles and PEG200, and said The micropore diameter of the silicon nanomaterial is 220nm; the encapsulation layer 1 is a metal member with an unclosed end and a cavity inside, and the interior of the encapsulation layer 1 is filled with STF11; the end cap 12 is set inside the unenclosed end of the encapsulation layer 1 The anti-collision beam support frame 14 is located on the outer surface of the packaging layer 1; the outer end surface of the mounting plate 2 is connected with the inner surface of the packaging layer 1 ...

Embodiment 3

[0044] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a vehicle bumper includes a packaging layer 1, a mounting plate 2, a fixing ring 3, a forward rod 41, a reverse rod 42, a short shaft 5, a long shaft 6, a T-shaped slider 7, a guide rail 8, a fastening Screw 9, cover 10, STF11, end cap 12, anti-collision beam support frame 14 and shear synergistic device, described STF11 is formed by stirring and mixing silicon dioxide nanoparticles and PEG200, the silicon dioxide nanomaterial The micropore diameter is 200nm; the encapsulation layer 1 is a metal member with an unclosed end and a cavity inside, and the interior of the encapsulation layer 1 is filled with STF11; the end cap 12 is set inside the unenclosed end of the encapsulation layer 1; the anti-collision beam The support frame 14 is arranged on the outer surface of the packaging layer 1; the outer end surface of the mounting plate 2 is connected with the inner surface of the packaging layer 1 through fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com