Preparing method for high-strength and high-toughness gradient martensite and austenite dual-phase steel

A high-strength, high-toughness, austenitic steel technology, applied in the field of steel and non-ferrous metal processing, can solve the problems of loss of plasticity and reduction of steel plasticity, and achieve the effect of improving toughness, tensile strength, and not changing shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

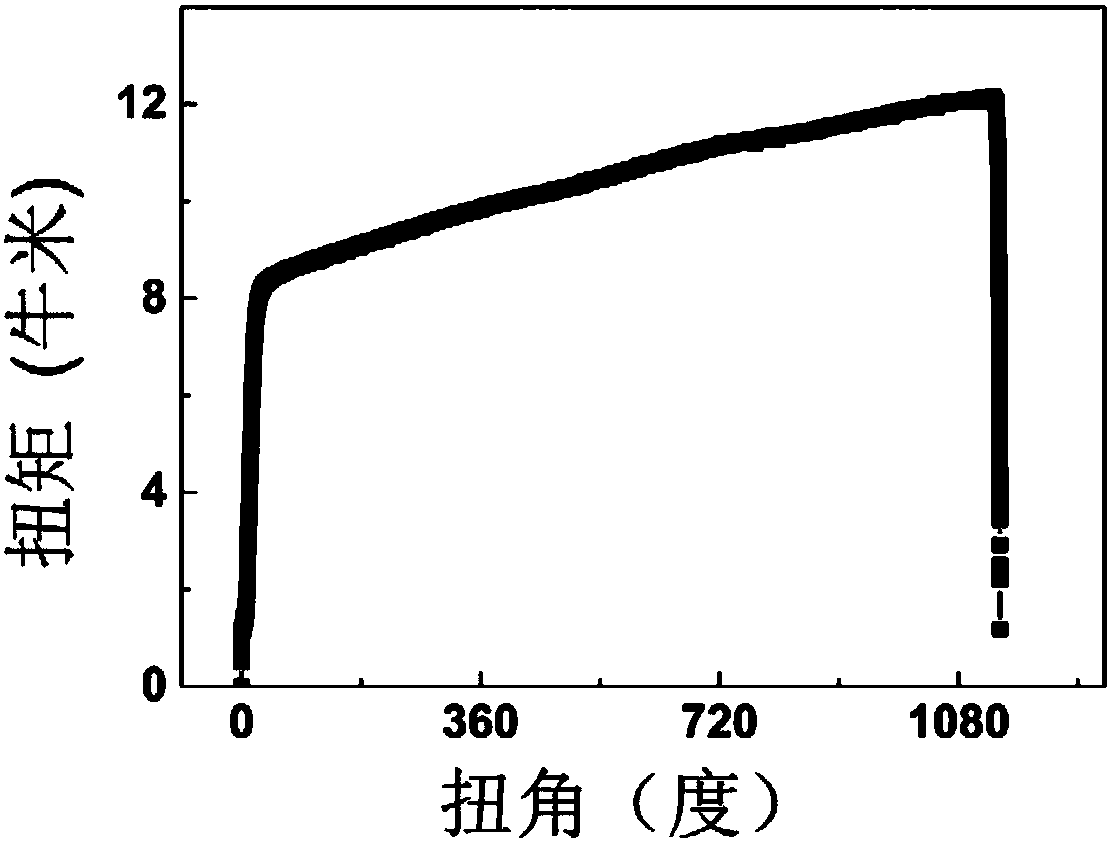

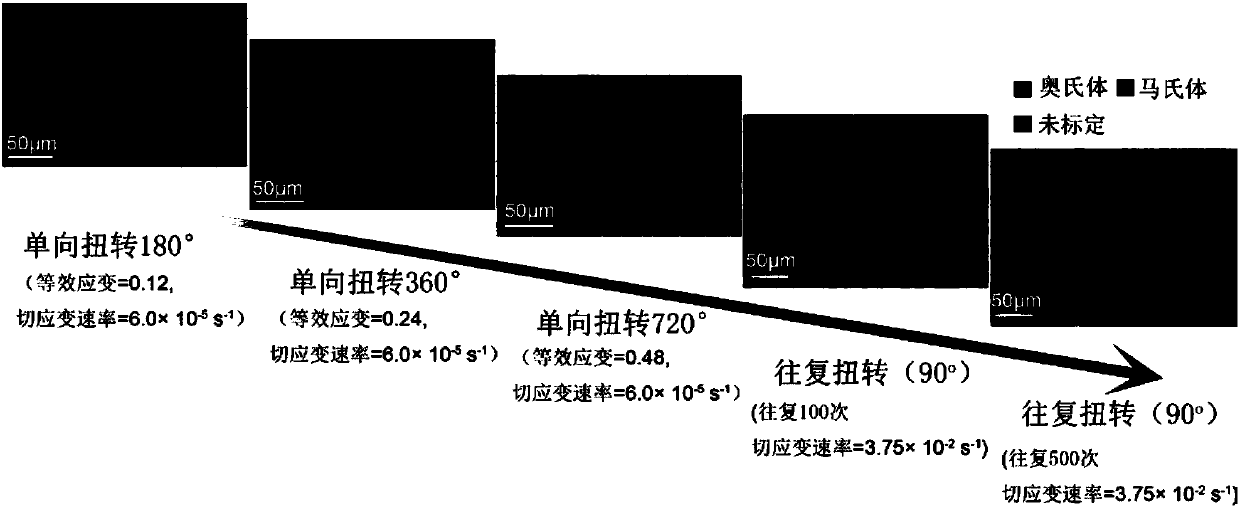

[0027] Such as figure 1 , image 3 , Figure 4 , Figure 6 As shown, the treatment of austenitic steel by unidirectional torsional plastic deformation can improve the tensile strength of existing austenitic steel. First, the commercial 304 austenitic stainless steel bar with a diameter of 10mm is subjected to solution treatment (water cooling) at 1050°C for half an hour, and then processed into a dog-bone shape with a circular cross section (thick at both ends, thin in the middle parallel section, and parallel section The diameter is 4mm) columnar sample, put the columnar sample on the torsion testing machine, and carry out torsion deformation, the temperature of torsion deformation is room temperature, the torsion method is one-way torsion, the torsion speed is 10° / min (slow speed), and the maximum shear rate of the edge is The strain rate is 6.0×10 -5 the s -1 , the torsion angles are 180°, 360° and 720° respectively. image 3 As shown, as the twist angle increases fro...

Embodiment 2

[0033] Such as Figure 5 As shown, the treatment of austenitic steel by unidirectional torsional plastic deformation can improve the tensile strength of existing austenitic steel. First, the commercial 304 austenitic stainless steel bar with a diameter of 10mm is subjected to solution treatment (water cooling) at 1050°C for half an hour, and then processed into a dog-bone shape with a circular cross section (thick at both ends, thin in the middle parallel section, and parallel section For a columnar sample with a diameter of 4mm, place the columnar sample on a torsion testing machine for torsion deformation. The temperature of the torsion deformation is room temperature, the torsion method is unidirectional torsion, the torsion speed is 720° / min (fast), and the maximum shear strain of the edge is The rate is 1.4×10 -2 the s -1 , and the twist angles are 90° and 180°, respectively.

[0034] Figure 5 a. Figure 5 As shown in c, after a unidirectional rapid twist of 90°, th...

Embodiment 3

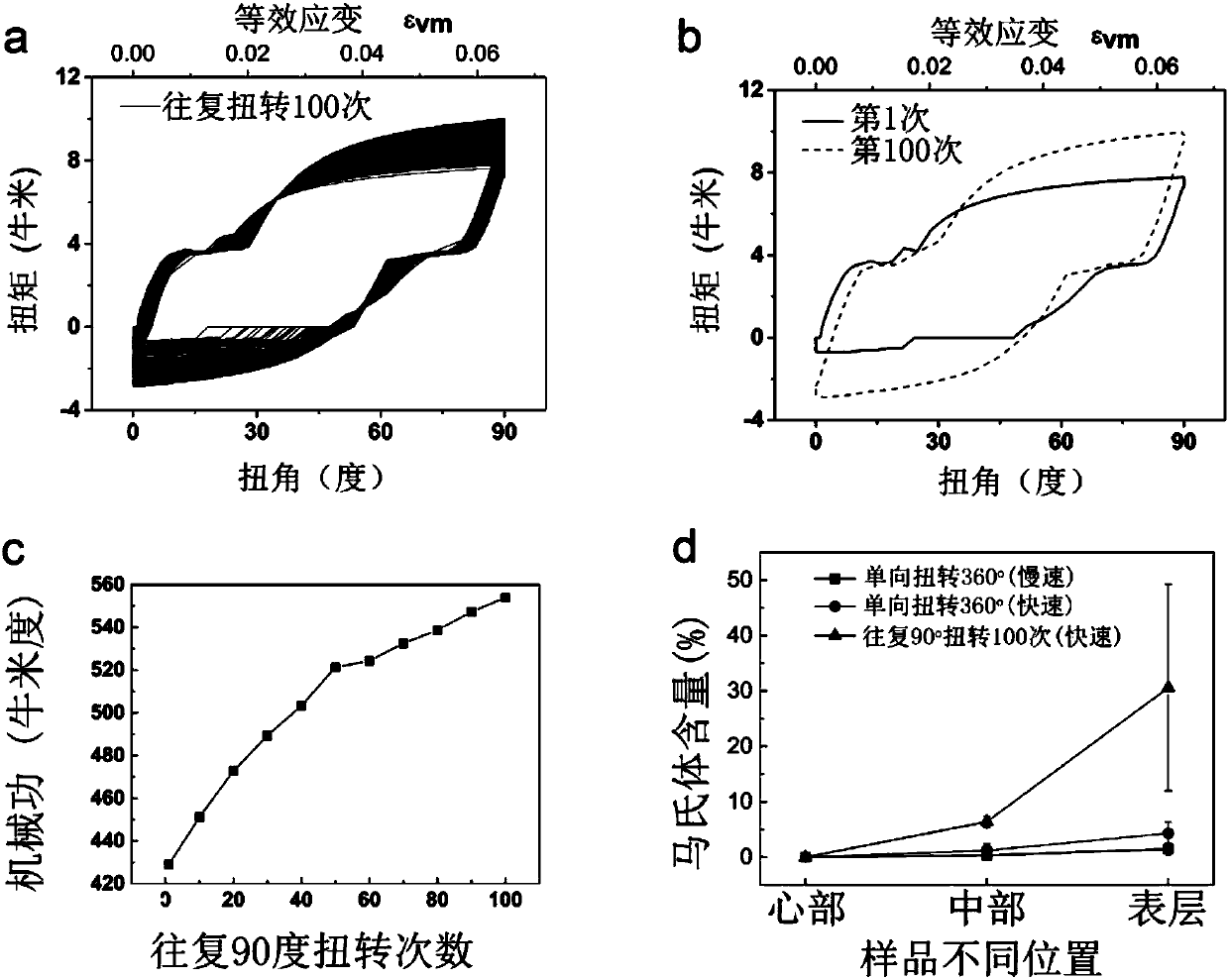

[0039] Such as figure 2 , image 3 , Figure 6 As shown, the austenitic steel is processed by plastic deformation of reciprocating 90° torsion to improve the tensile strength of the existing austenitic steel. First, the commercial 304 austenitic stainless steel bar with a diameter of 10mm is subjected to solution treatment (water cooling) at 1050°C for half an hour, and then processed into a dog-bone shape with a circular cross section (thick at both ends, thin in the middle parallel section, and parallel section The diameter is 4mm) columnar sample, the columnar sample is placed on the torsion testing machine, carries out torsion deformation, the temperature of torsion deformation is room temperature, the torsion mode is reciprocating 90° torsion, the torsion speed is 1800° / min, and the maximum shear strain rate of the edge is 3.75×10 -2 the s -1 , the times of torsional deformation are 1 time, 100 times and 500 times respectively.

[0040] When twisting back and forth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com