Non-woven fabric and filter

A technology of non-woven fabrics and fibers, applied in the field of non-woven fabrics and filters, which can solve the problems of low collection efficiency and achieve the effect of excellent collection efficiency and small fiber diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

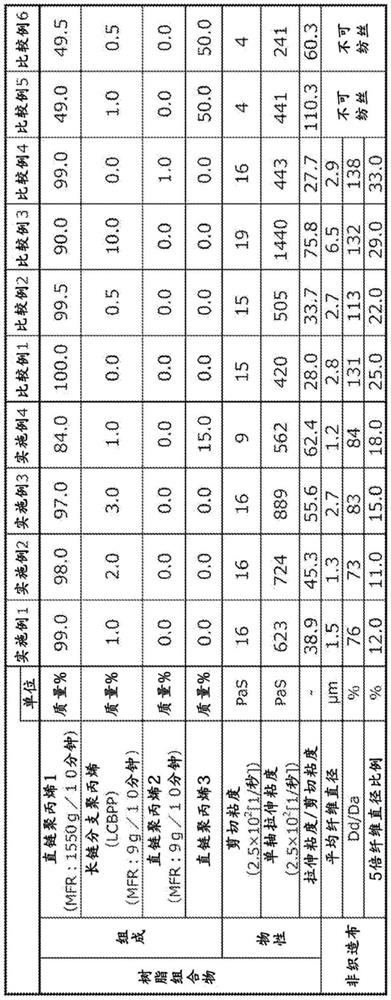

[0216] 99.0 parts by mass of Achieve 6936G2 (product name) (manufactured by ExxonMobil, weight-average molecular weight: 55,000 propylene-based polymer, MFR; 1550 g / 10 minutes) as linear polypropylene 1 (high molecular weight linear polypropylene) was mixed with Melt 1.0 parts by mass of WAYMAX MFX3 (product name) (manufactured by Nippon Polypro Co., Ltd., MFR; 9, long-chain branched polypropylene having a branched chain structure with 10 or more carbon atoms) as long-chain branched polypropylene (LCBPP). and mixed to obtain a resin composition.

[0217] Table 1 shows the shear viscosity, the uniaxial extensional viscosity, and the ratio of the uniaxial extensional viscosity to the shear viscosity (uniaxial extensional viscosity / shear viscosity) of the obtained resin composition. In addition, the uniaxial extensional viscosity and shear viscosity were measured by the method mentioned above.

[0218] The resin composition obtained above was supplied to a die head, and from a d...

Embodiment 2~ Embodiment 4 and comparative example 1~ comparative example 3

[0221] (Example 2-Example 4 and Comparative Example 1-Comparative Example 3, Comparative Example 5 and Comparative Example 6)

[0222]In Example 1, except having changed the ratio of the composition of the resin composition shown in Table 1, it carried out similarly to Example 1, and obtained the melt blown nonwoven fabric. Table 1 shows the physical property values of the obtained resin composition and melt-blown nonwoven fabric, respectively.

[0223] In addition, the uniaxial extensional viscosity, the shear viscosity, and the average fiber diameter were measured and calculated by the above-mentioned methods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com