Ruthenium oxide powder, composition for thick film resistor elements using same, and thick film resistor element

A thick film resistor, ruthenium oxide technology, applied in thick film resistors, ruthenium/rhodium/palladium/osmium/iridium/platinum compounds, resistors, etc., can solve the problems of low crystallinity and achieve high crystallinity, Excellent economical efficiency and the effect of suppressing grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

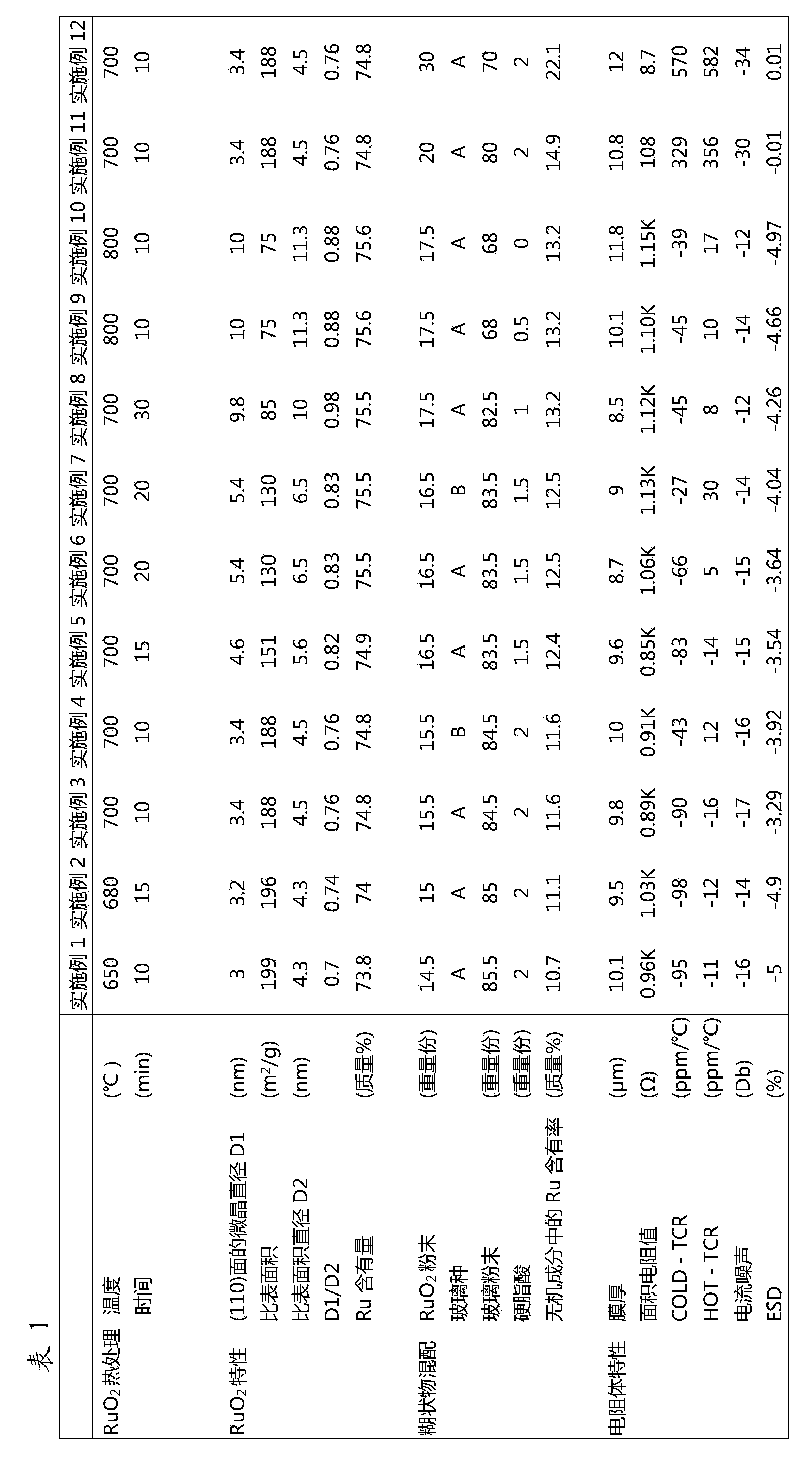

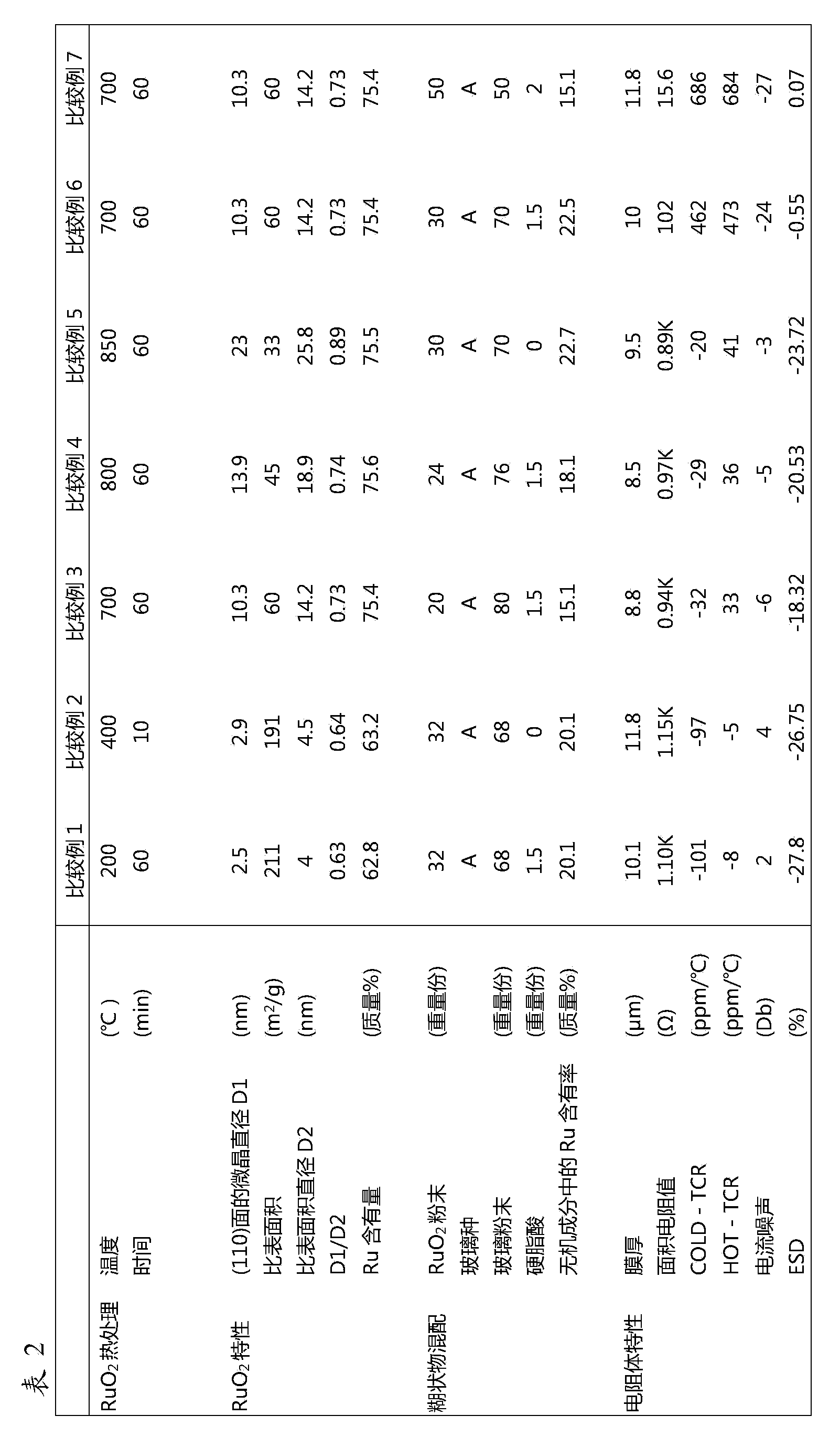

[0100] In Example 1, an aqueous solution in which potassium ruthenate was dissolved was used as a raw material, a precipitate of ruthenium oxide was synthesized in the aqueous solution, the solid-liquid was separated, washed, and dried at 80° C. to obtain a ruthenium oxide powder. The dried ruthenium oxide was an oxide hydrate having a ruthenium content of 61.5% by mass. The dried ruthenium oxide powder was heat-treated at 650° C. for 10 minutes to obtain ruthenium oxide (RuO 2 )powder. On the other hand, in Examples 2 to 12, different from Example 1, the dried ruthenium oxide powder was heat-treated in the range of 680 to 800° C. for 10 to 30 minutes as shown in Table 1.

[0101] The resulting ruthenium oxide (RuO 2 ) powder, together with glass powder with an average particle size of 1.5 μm, is dispersed in a carrier containing ethyl cellulose at 5% to 15% by mass and terpineol at 75% to 95% by mass to form a thick film resistor paste. As for the glass powder, glass powde...

Embodiment 13 to 18

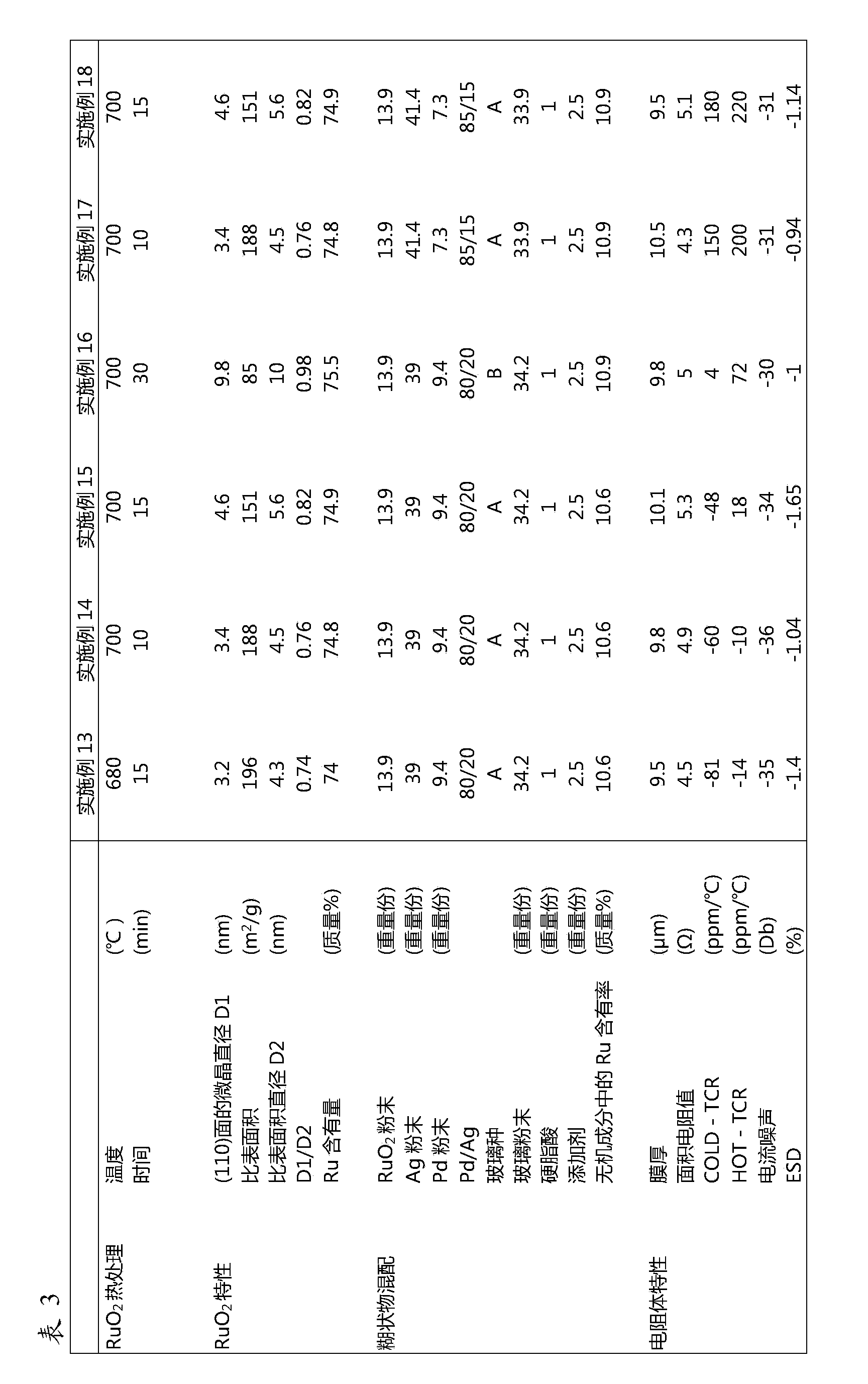

[0110] In addition to the raw materials used in Examples 1 to 12, silver (Ag) powder with an average particle diameter of 1.0 μm, palladium (Pd) powder with an average particle diameter of 0.3 μm and additives, in Examples 13 to 18, the The area resistance value of the formed thick film resistor was adjusted so as to be approximately 5Ω.

[0111] Regarding the preparation of thick film resistor paste, compared to ruthenium oxide (RuO 2 ) powder, Ag powder, and conductive powder of Pd powder, glass powder, and additive powder in total of 100 parts by weight, the carrier was compounded in an amount of 43 parts by weight. At this time, stearic acid was dispersed in the carrier with a three-roll mill to prepare a thick-film resistor paste. These thick-film resistor pastes were printed, dried, and fired in the same manner as in Examples 1 to 12, and evaluated. The evaluation results are shown in Table 3.

[0112] In Examples 13 to 18, evaluation was performed in the same manner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com