Thick-film resistance paste with electrostatic discharge resistance and low encapsulation change rate

A technology of thick film resistors and pastes, applied in thick film resistors, resistors, conductive materials dispersed in non-conductive inorganic materials, etc., can solve resistance drift, resistance drift, product encapsulation change rate Unqualified and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

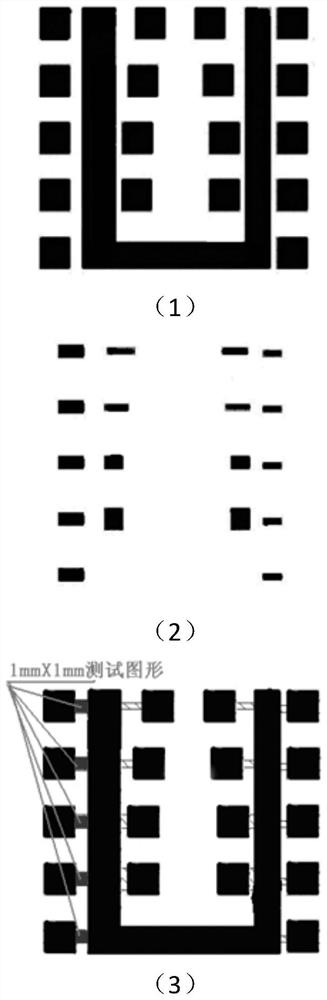

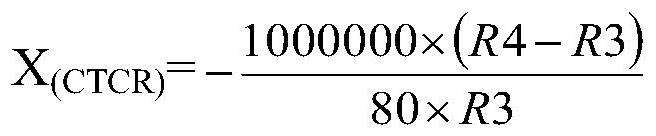

Image

Examples

Embodiment 1

[0120] In this embodiment, six kinds of glass powders are prepared: glass powder A1, glass powder A2, glass powder A3, glass powder B1, glass powder B2, and glass powder B3. As shown in Table 1, the formula of each glass powder is specifically:

[0121] Glass powder A1: 35 parts by weight of PbO, 30 parts by weight of SiO 2 , 20 parts by weight of CaO, 5 parts by weight of Al 2 o 3 , 7 parts by weight of B 2 o 3 , 0.5 parts by weight of Na 2 O, the ZnO of 2.5 parts by weight;

[0122] Glass powder A2: 35 parts by weight of PbO, 28.44 parts by weight of SiO 2 , 20 parts by weight of CaO, 5 parts by weight of Al 2 o 3 , 7 parts by weight of B 2 o 3 , 0.5 parts by weight of Na 2 The graphdiyne powder of the ZnO of O, 2.5 weight parts, 1.56 weight parts;

[0123] Glass powder A3: 35 parts by weight of PbO, 29.375 parts by weight of SiO 2 , 20 parts by weight of CaO, 5 parts by weight of Al 2 o 3 , 7 parts by weight of B 2 O3, 0.5 parts by weight of Na 2 The graphd...

Embodiment 2

[0132] In this embodiment, slurry 1 was prepared, and the film thickness, resistance value, positive temperature coefficient, negative temperature coefficient, electrostatic discharge and encapsulation change rate of the thick film resistor prepared from slurry 1 were measured.

[0133] The preparation process of slurry 1 is as follows:

[0134] Step 1: Weigh RuO 2 3g, Pb 2 Ru 2 o 613.3g, glass powder A1 32g, glass powder B1 16g, ZrSiO 4 5g, MnO 2 0.5g, graphdiyne powder 0.5g, organic carrier 29.7g;

[0135] Step 2: Use a glass rod to stir the solid powder and organic carrier in step 1 evenly, and leave it for more than 1 hour to complete the infiltration;

[0136] Step 3: roll on the upper three-roll machine to make the fineness ≦5 μm, and obtain the slurry 1.

[0137] Slurry 1 was screen printed, leveled, dried at 150°C for 10 minutes, and sintered in a tunnel furnace according to the thick film resistance sintering curve with a peak temperature of 850°C, a duratio...

Embodiment 3

[0139] In this embodiment, slurry 2 was prepared, and the film thickness, resistance value, positive temperature coefficient, negative temperature coefficient, electrostatic discharge and encapsulation change rate of the thick film resistor prepared from slurry 2 were measured.

[0140] The preparation process of slurry 2 is as follows:

[0141] Step 1: Weigh RuO 2 3g, Pb 2 Ru 2 o 6 13.3g, glass powder A1 32g, glass powder B1 16g, ZrSiO 4 5g, MnO 2 0.5g, graphdiyne powder 0.2g, organic carrier 30g;

[0142] Step 2: Use a glass rod to stir the solid powder and organic carrier in step 1 evenly, and leave it for more than 1 hour to complete the infiltration;

[0143] Step 3: rolling on the upper three-roll machine to make the fineness ≤ 5 μm, and obtain the slurry 2.

[0144] Slurry 2 was screen printed, leveled, dried at 150°C for 10 minutes, and sintered in a tunnel furnace according to the thick film resistance sintering curve with a peak temperature of 850°C, a dur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com