Method for manufacturing microwave power device by using double level polysilicon device structure

A polysilicon device, microwave power technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as higher power output of unfavorable devices, large extrinsic base area, and device reliability discounts. The effect of improving power output characteristics, avoiding registration deviation, and reducing parasitic capacitance and parasitic resistance components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The method for preparing a microwave power device with a double-layer polysilicon emitter structure of the present invention will be described in detail below in conjunction with the accompanying drawings:

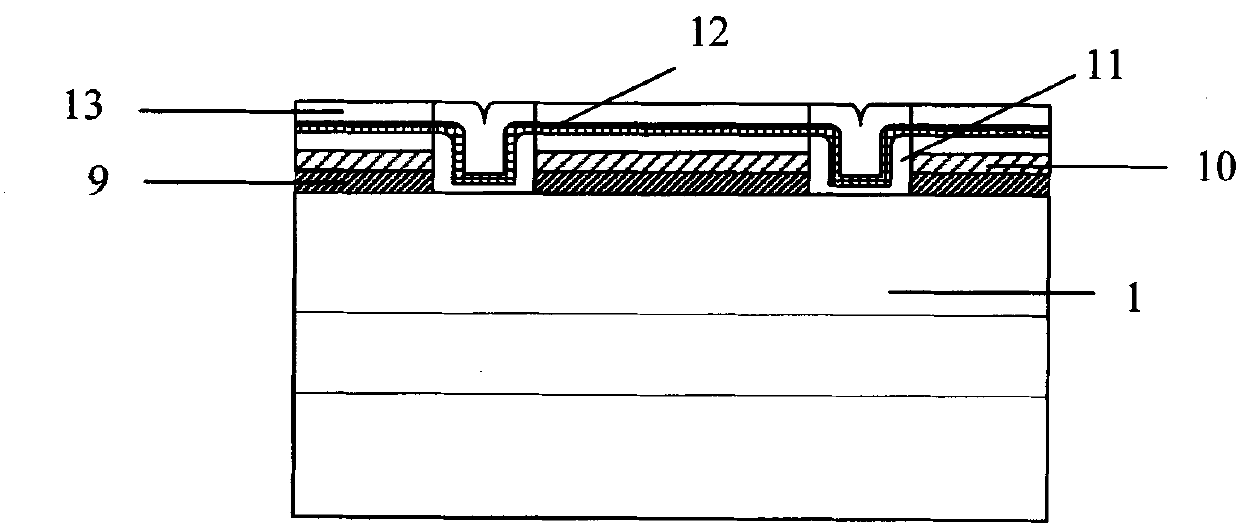

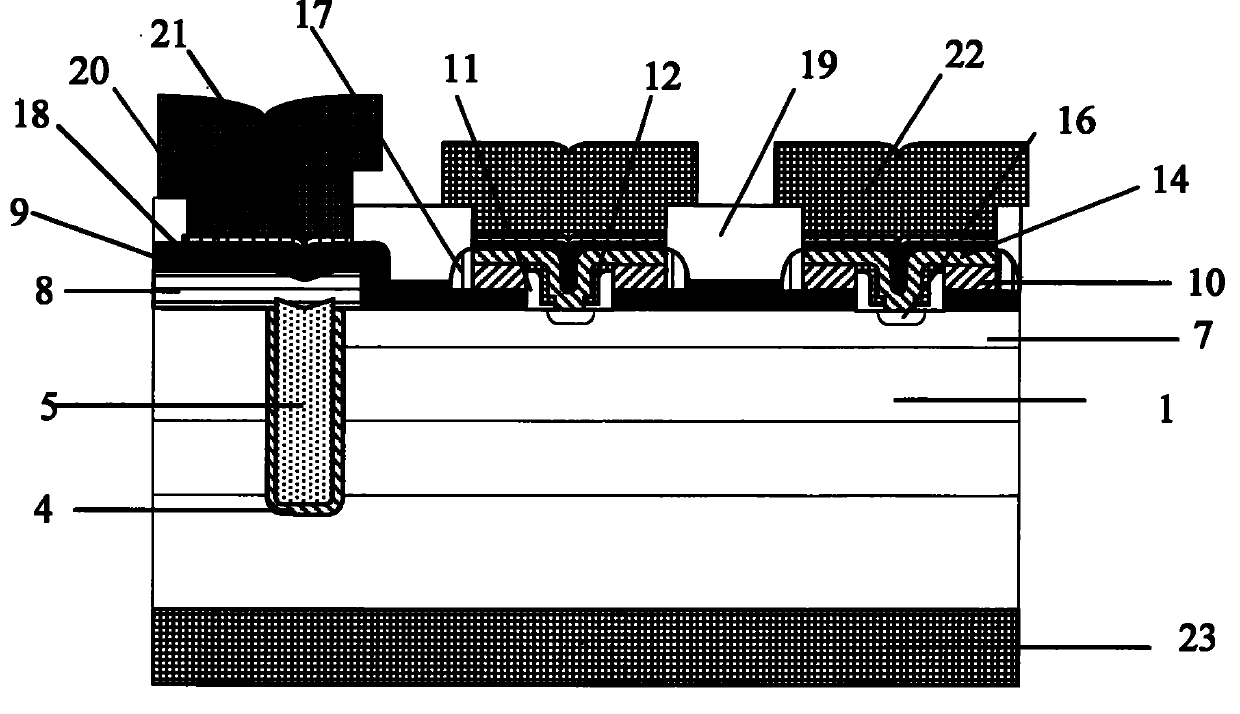

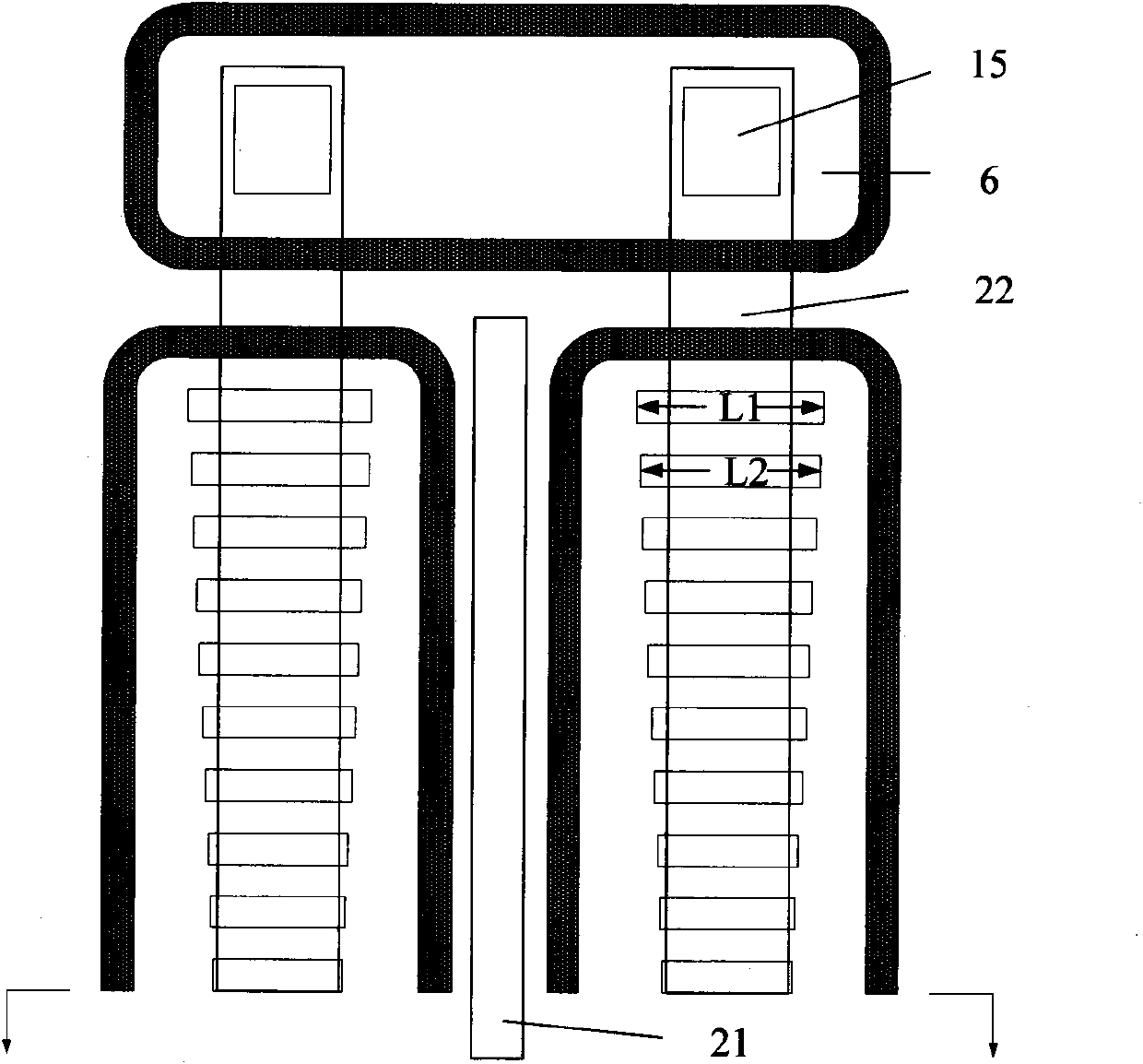

[0040] Such as figure 1 As shown, the present invention utilizes self-alignment technology to prepare a microwave power device with a double-layer polycrystalline silicon device structure. After the process, the insulating oxide layer 4 is thermally grown, undoped polysilicon 5 is deposited and planarized to form a deep trench isolation structure; the area surrounded by the deep trench is implanted with boron ions to obtain the implanted area 6 and the series ballast resistance of the device. Active base region 7, P-type doped polysilicon 9 and dielectric isolation layer 10 are successively placed on the active base region 7 and field oxygen 8, and the dielectric isolation layer 10 is anisotropically etched by plasma etching RIE and ICP and other equipment respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com