Internal temperature control liquid piston device for isothermal compressed air energy storage

A compressed air energy storage, high-pressure gas technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve problems such as large energy loss, solve damage and harm, help temperature control, and improve energy utilization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The embodiments will be described in detail below in conjunction with the accompanying drawings.

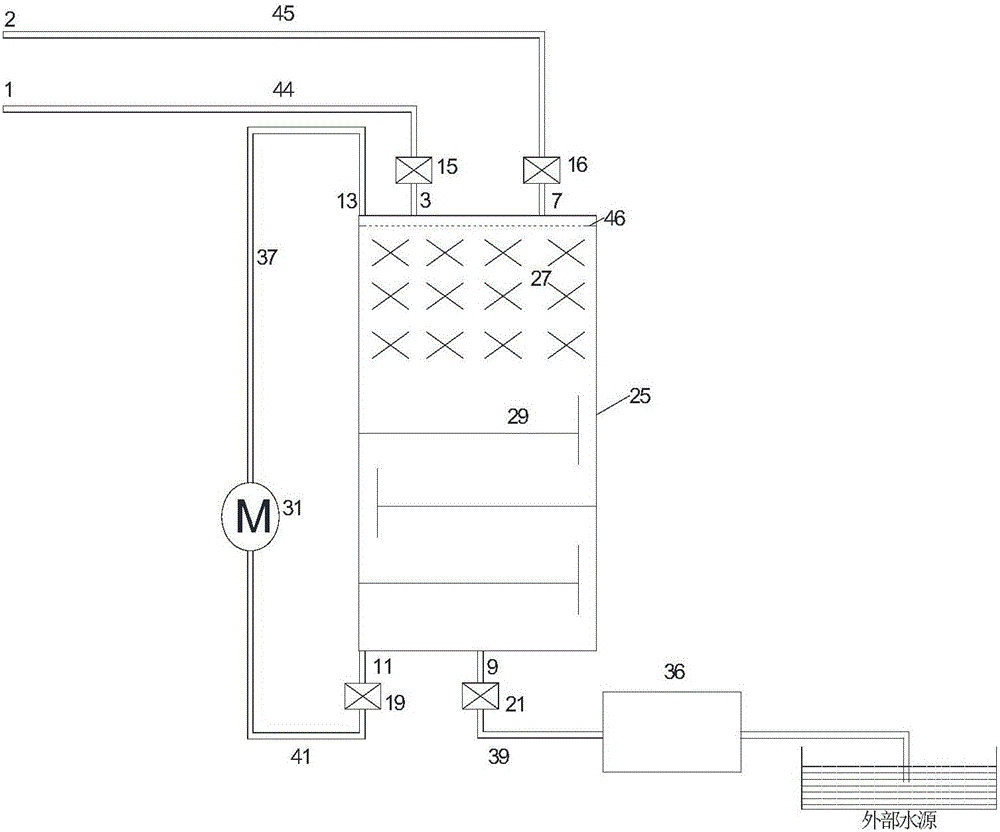

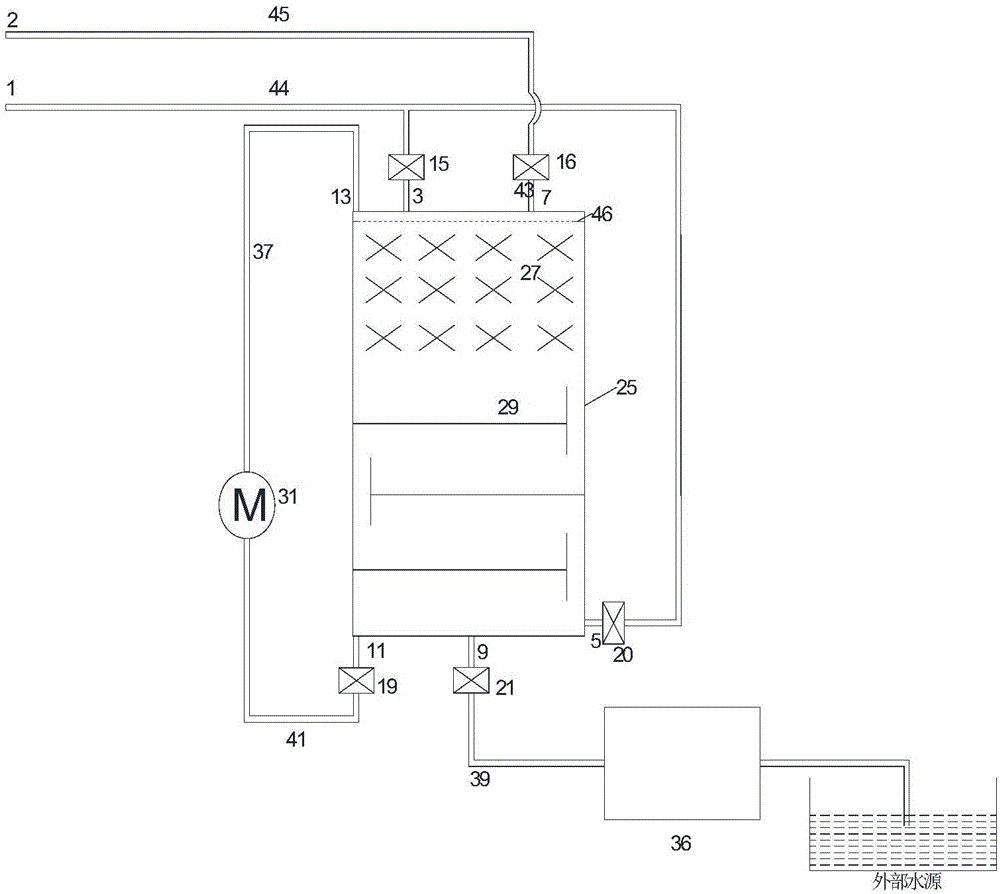

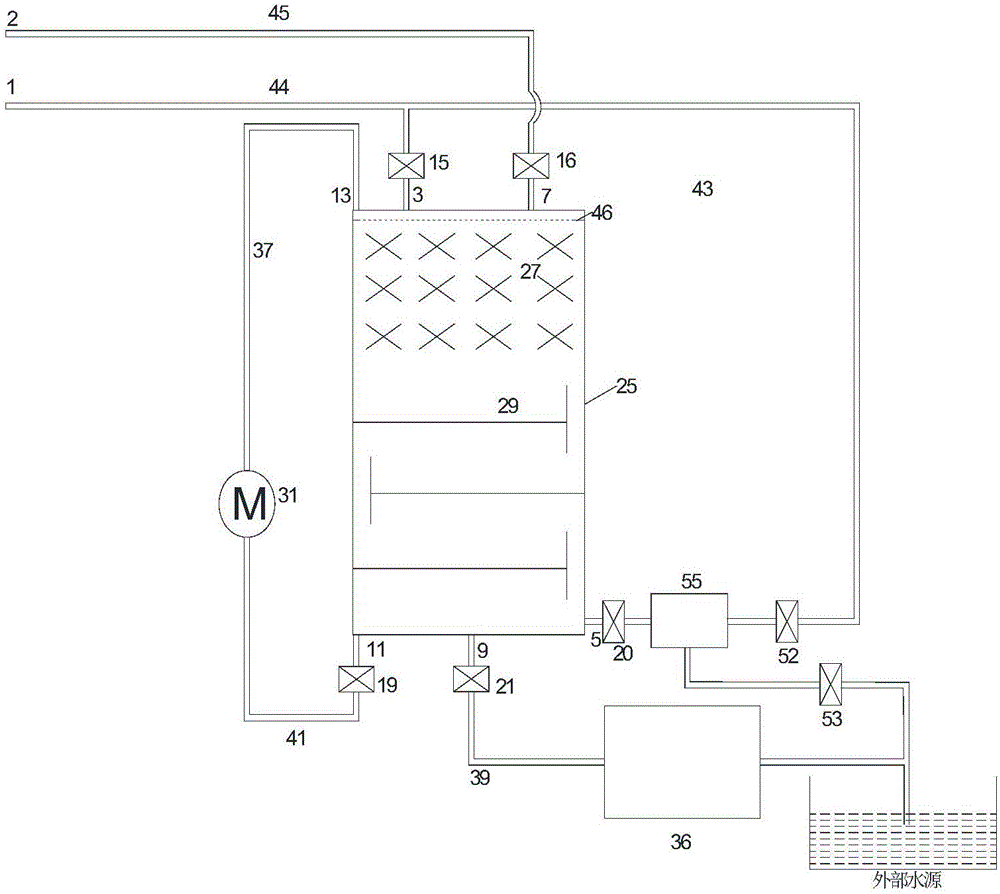

[0045] figure 1 and figure 2 It is two connection methods of high-pressure pipelines for internal temperature-controlled liquid piston devices used for isothermal compressed air energy storage. The pressure vessel 25 is connected to the high-pressure gas pipeline 1, the low-pressure gas pipeline 2, and the hydraulic potential energy conversion device 36, and the two ends of the temperature control liquid injection device 31 are respectively connected to the top and bottom of the pressure vessel, and the hydraulic potential energy conversion device 36 is connected to an external water source; the pressure vessel A liquid distributor 46, a filler 27, and a tray 29 are provided from top to bottom.

[0046] figure 1 The connection mode of the high-pressure gas pipeline shown is: the high-pressure gas pipeline is only connected to the top of the pressure vessel, and serves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com