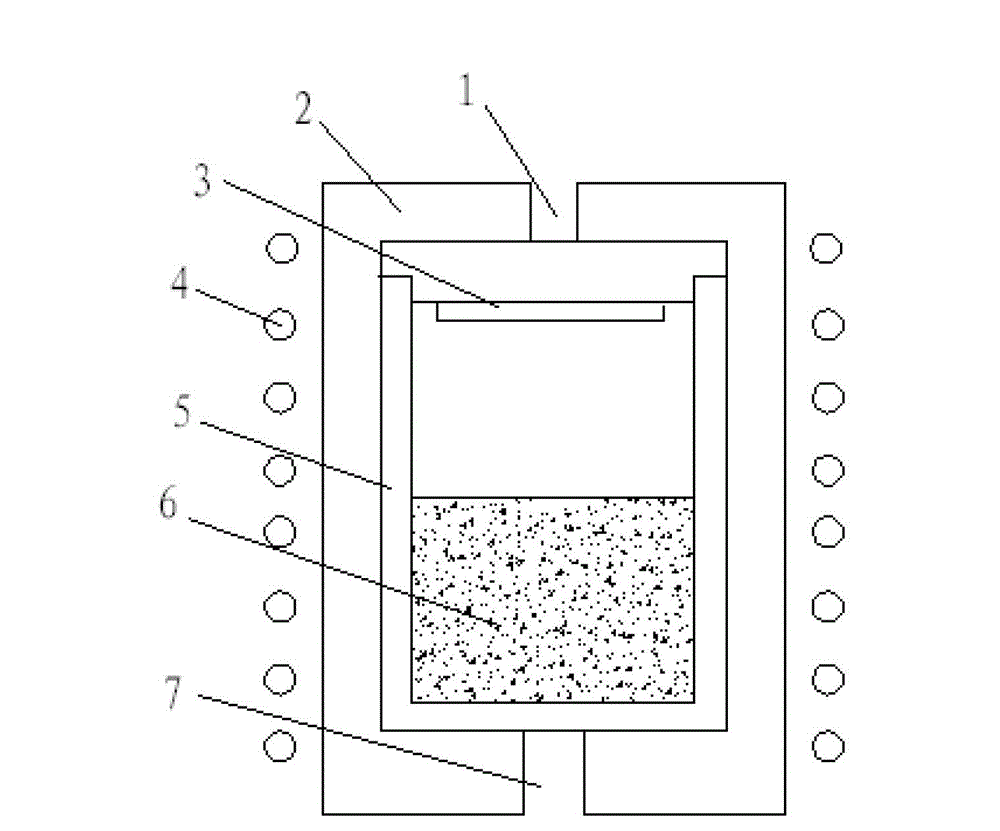

Silicon carbide crystal growth crucible for increasing utilization rate of power sources

A crystal growth, silicon carbide technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of low utilization rate of silicon carbide powder source, low average crystal growth rate, etc., to reduce the phenomenon of secondary crystallization , the effect of improving the utilization rate and the average growth rate of the crystal, and increasing the temperature of the powder source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

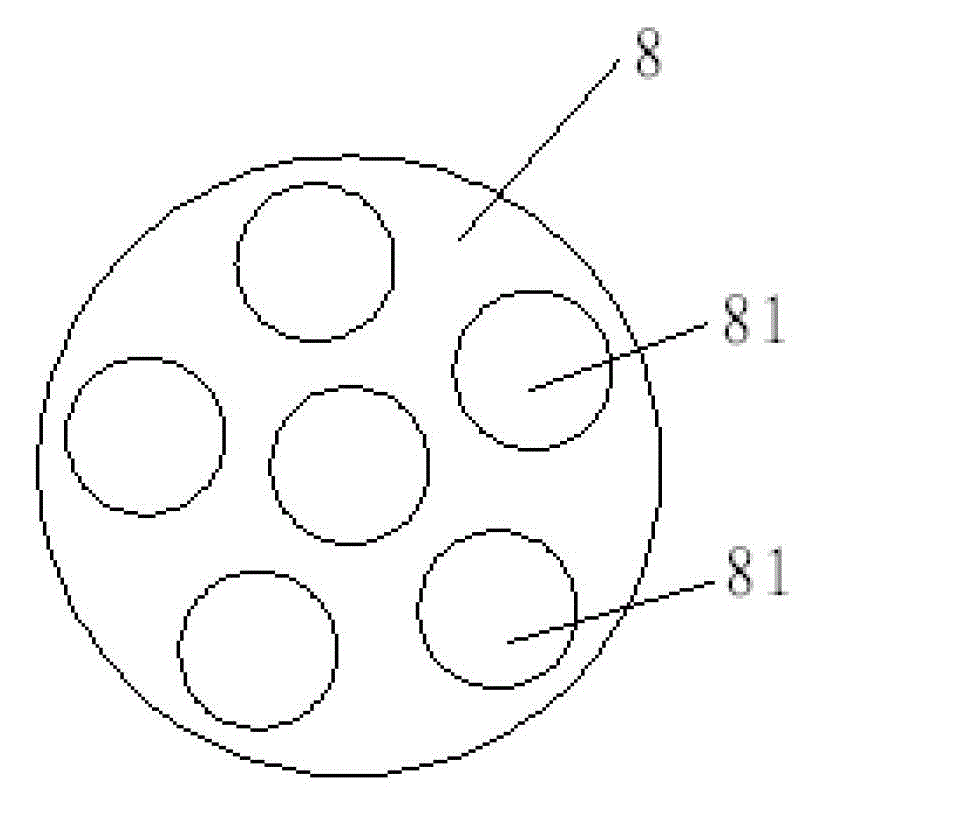

[0017] Such as figure 2 As shown, the present invention includes a crucible body 8 whose external shape is cylindrical and made of graphite. The cross-sections of the regions 81 are all circular and are evenly arranged in a honeycomb shape in the horizontal direction, specifically: one of the circular subpackaging regions 81 is located at the center of the crucible body 8, and the other five are distributed circumferentially outside it. The crucible body 8 has an integrated structure, that is, the intervals between the five sub-packaging regions 81 are of the same material and integrated structure, which is conducive to reducing the radial temperature gradient of the silicon carbide source.

Embodiment 2

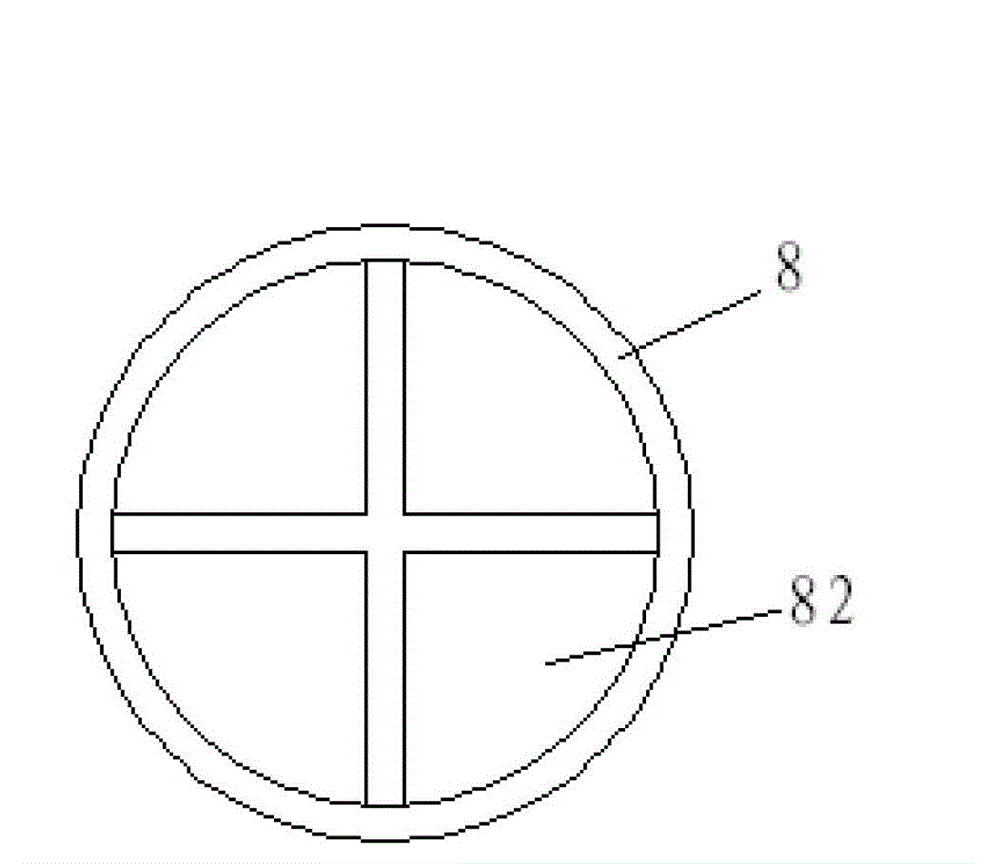

[0019] Such as image 3 As shown, the present invention includes a crucible body 8 whose external shape is cylindrical and made of graphite. The inner cavity of the crucible body includes four fan-shaped sub-package areas 82 for containing silicon carbide powder sources. The four fan-shaped sub-package areas 82 The cross-sections are fan-shaped and distributed along the center and circumference of the crucible body in the horizontal direction. The crucible body 8 has an integrated structure, that is, the intervals between the four fan-shaped sub-packaging regions 82 are of the same material and integrated structure, which is beneficial to reduce the radial temperature gradient of the silicon carbide source.

[0020] In the present invention, a crucible with an unreasonable inner cavity partition form is selected according to needs, and the shape and number of subpackage areas in the crucible inner cavity are determined according to the requirements of the working conditions, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com