Heat pipe uniform temperature heat dissipation device for disc vehicle brake

A vehicle braking and cooling device technology, applied in the direction of brakes, cooling brakes, vehicle components, etc., can solve the problems of instantaneous temperature and average temperature brake braking efficiency decline, etc., and achieves simple and easy technical means, low instantaneous temperature and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

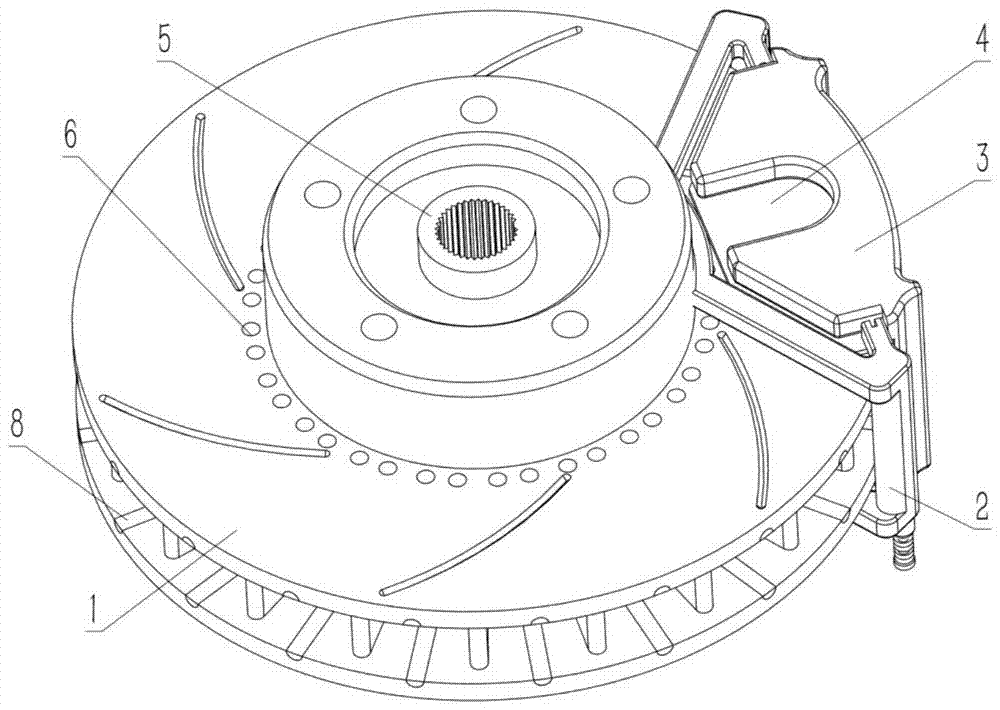

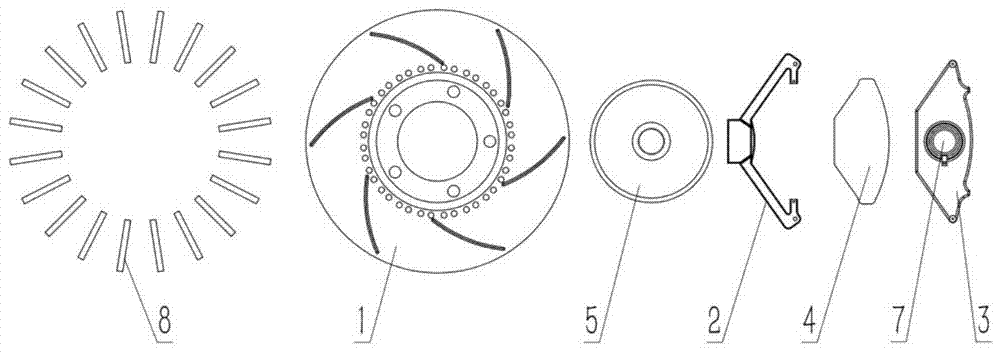

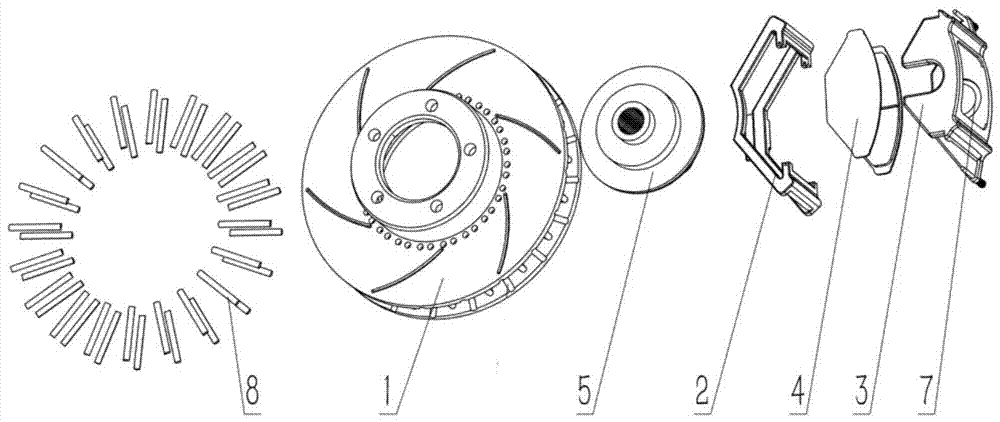

[0034] Such as Figure 1 to Figure 10 shown. The heat pipe uniform temperature cooling device for disc vehicle brakes of the present invention comprises a brake disc composed of two oppositely arranged brake discs 1; heat pipe arrays arranged in a ring shape are respectively arranged on the opposing surfaces of the two brake discs 1, The heat pipe array is fixed on the brake disc 1 in a surface contact manner through the heat pipe grooves 11 provided on the brake disc. The inner periphery of the brake disc 1 is provided with a plurality of cooling holes 6 arranged in a ring shape.

[0035] Such as figure 2 , 6 shown. The heat pipe array is composed of a plurality of straight heat pipes 8 or a plurality of U-shaped heat pipes 9 .

[0036] Such as Figure 7 , 8 shown. Radiating fins 10 are arranged on the body of the U-shaped heat pipe 9 .

[0037] Such as Figure 9 , 10 shown. A porous heat dissipation structure 12 may also be provided between two opposing pipe bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com