A large-size sic single crystal growth device and its working method

The technology of a growth device and working method, which is applied in the field of large-size SiC single crystal growth devices, can solve the problems of convex crystal growth interface, unfavorable crystal quality, large temperature difference, etc., achieve fast heating rate, improve crystal growth morphology, reduce Effect of Small Radial Temperature Gradients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

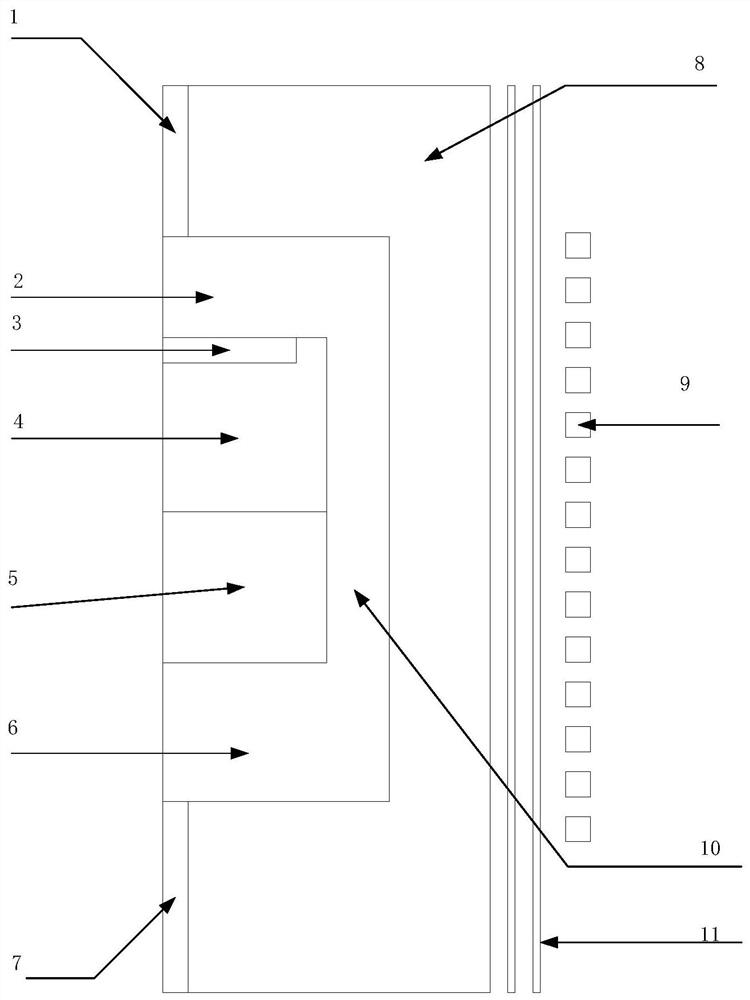

[0033] Such as figure 1 shown.

[0034] A large-size SiC single crystal growth device, including a crucible, a quartz tube 11 and an induction coil 9 arranged sequentially from the inside to the outside; the crucible includes a crucible cover 2, a crucible wall 10 and a crucible bottom 6; the upper and lower sides of the crucible An upper temperature measuring hole 1 and a lower temperature measuring hole 7 are respectively arranged on the side; the crucible cover 2, crucible wall 10 and crucible bottom 6 enclose a growth chamber. The induction coil 9 is parallel to the crucible wall 10, and the central axis of the induction coil 9 coincides with the central axis of the crucible.

[0035] A heat insulating material is arranged between the crucible and the quartz tube 11; the upper temperature measuring hole 1 is arranged in the heat insulating material on the upper side of the crucible; the lower temperature measuring hole 7 is arranged in the crucible inside the insulation ...

Embodiment 2

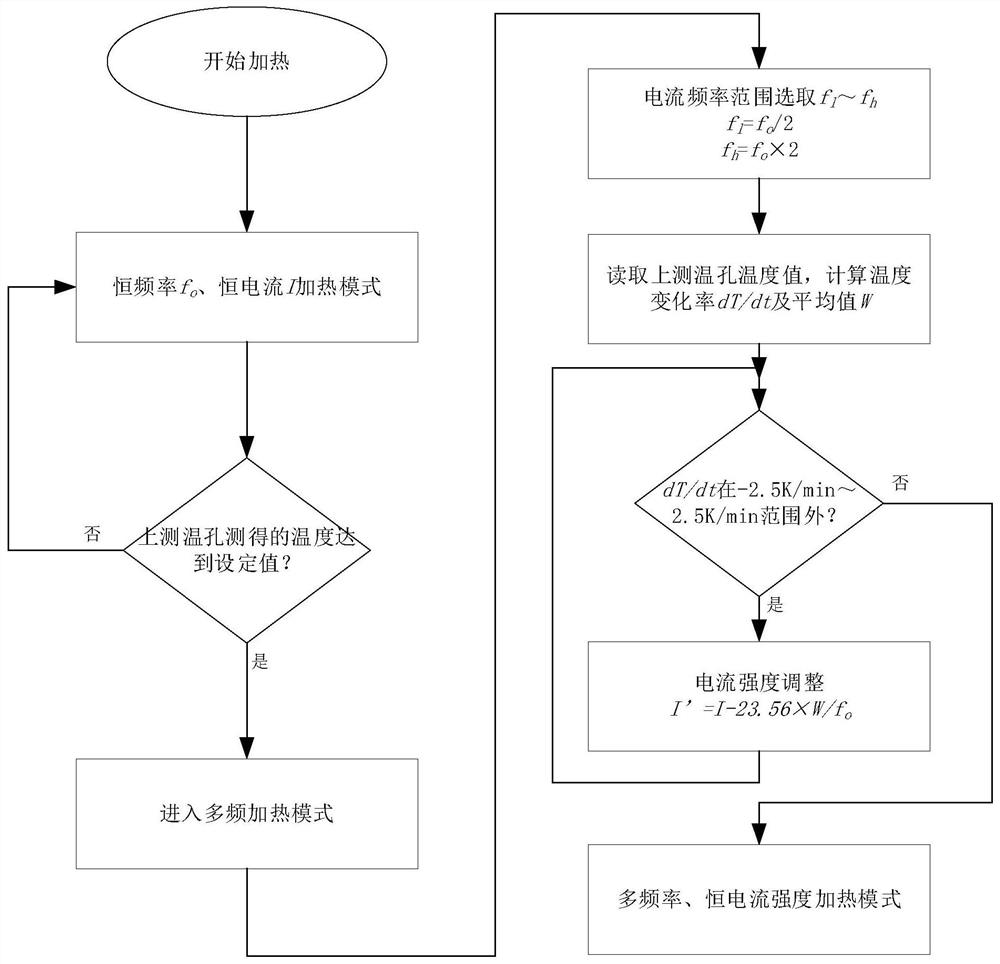

[0039] Such as figure 2 shown.

[0040] A working method of the large-scale SiC single crystal growth device as described in Embodiment 1, comprising the following steps:

[0041] 1) The growth chamber is heated by using a constant frequency and constant intensity current heating mode; the ranges of the constant frequency and constant intensity of the current are 10 kHz and 200 A, respectively.

[0042] 2) During the operation of the current heating mode with constant frequency and constant intensity, the temperature T in the growth chamber is detected through the upper temperature measuring hole until the temperature T in the growth chamber reaches the set temperature; the set temperature is 2373K.

[0043] 3) Take the constant frequency in step 1) as the center frequency f o Carry out multi-frequency heating; adjust the heating current intensity;

[0044] The adjustment process of heating current frequency is:

[0045] to the center frequency f o The high-frequency and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com