Cyclone separator

A technology of cyclone separator and cyclone, which is applied in the direction of separation method, dispersed particle separation, cyclone device, etc., can solve the problems of central tube rupture and thermal stress load increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

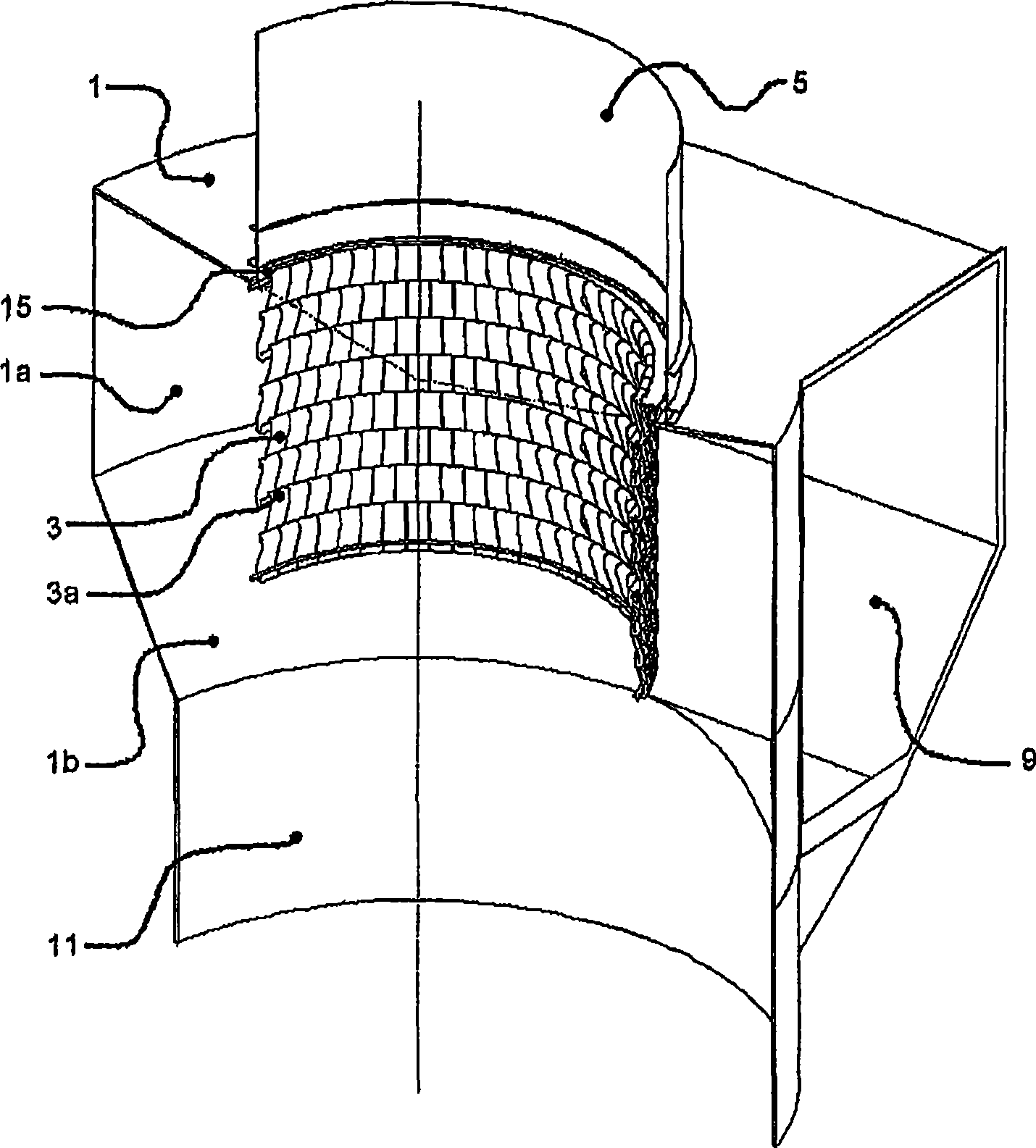

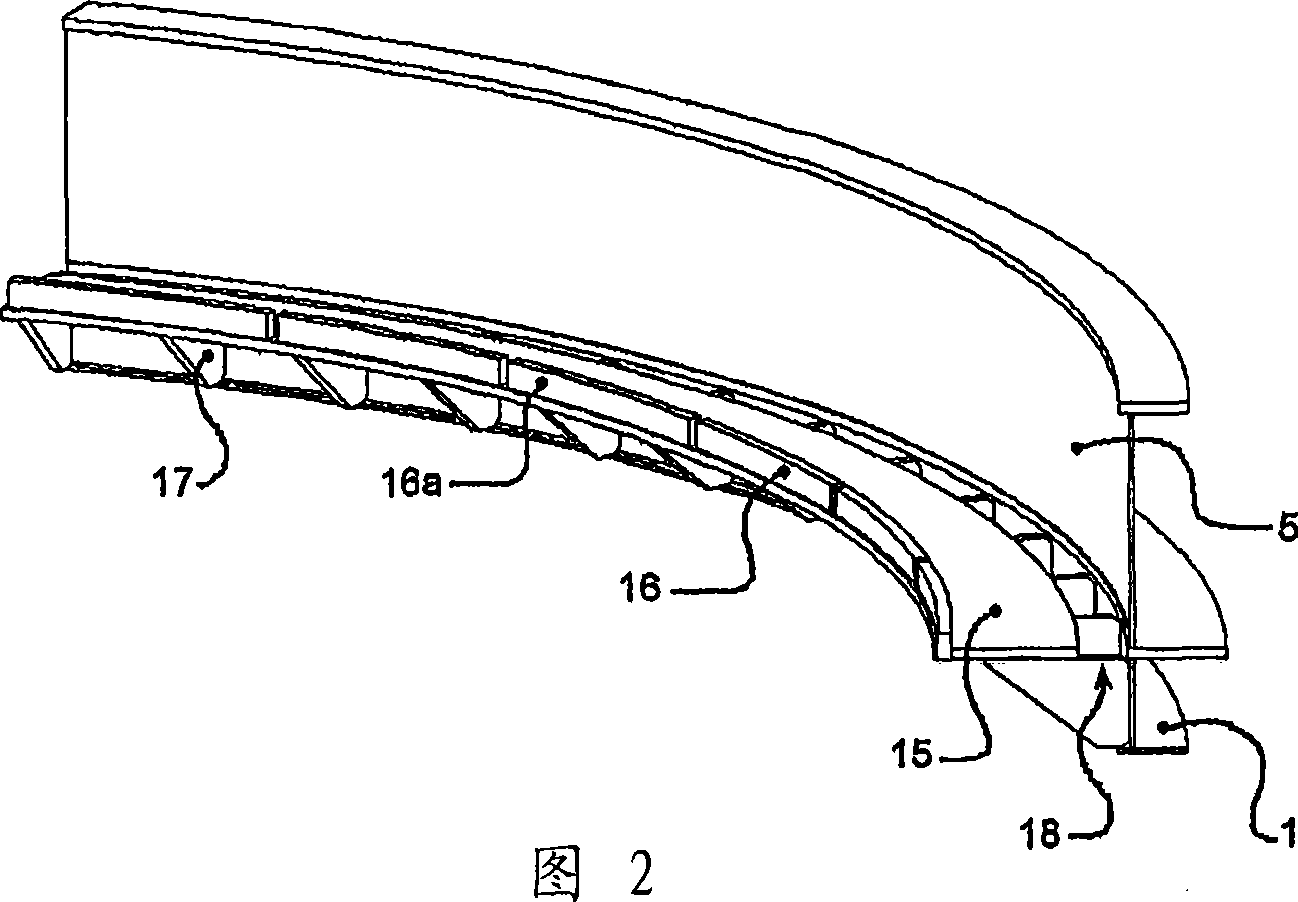

[0016] exist figure 1 It can be seen in FIG. 2 that the cyclone separator comprises a cyclone housing 1 . The cyclone housing 1 has: an upper cylindrical part 1a and a lower conical part 1b; a tangential inlet 9 for introducing the suspension to be separated; an outlet 11 at the bottom of this conical part for diverting a part of the suspension and a central pipe 3 that projects axially into the cyclone housing 1 for diverting the second portion of the suspension via a discharge pipe 5 .

[0017] The central pipe 3 consists of a plurality of sections 3 a which are suspended from a support 15 at the upper end of the cyclone housing 1 . The support 15 comprises an upwardly projecting flange 16 which, as shown, is divided into a plurality of segments 16a.

[0018] According to the invention, the cyclone comprises a plurality of conveying means 17 , shown here as triangular brackets 17 , fixed to and evenly distributed on the innermost part of the discharge pipe 5 . A support i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com