A liquid phase growth silicon carbide seed crystal shaft device

A silicon carbide seed and liquid phase growth technology, which is applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of uncontrollable crystal quality, achieve the effect of small stress, simple structure, and reduce radial temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

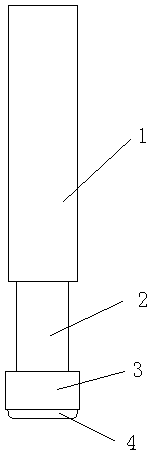

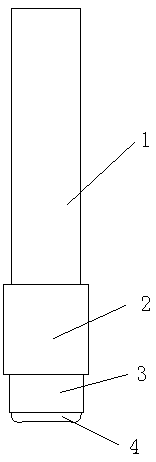

[0019] As shown in the accompanying drawings, a silicon carbide seed axis device for liquid phase growth is characterized in that it includes a moving connection part 1, a heat resistance part 2 and a graphite platform 3 that are detachably connected in sequence, and the other end of the graphite platform A seed crystal 4 is attached.

[0020] The heat-resisting part 2 is a heat-resisting material whose thermal conductivity is lower than that of graphite and does not react with silicon vapor. The heat-resisting material can be graphite fiber (insulation material), graphite with different thermal conductivity, stainless steel , marble, etc.

[0021] The seed crystal 4 may be square, circular or polygonal.

[0022] The shape of the graphite platform 3 is the same as that of the seed crystal 4, and the size is not smaller than the size of the seed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com