Raw material sintering process of silicon carbide crystals grown by PVT (physical vapor deposition) method

A technology of silicon carbide and raw materials, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of reduced sublimation decomposition rate of silicon carbide powder source, reduced growth rate of silicon carbide crystal, and reduced effective transportation efficiency, etc. Achieve the effects of weakening crystallization, reducing radial temperature gradient, and increasing average growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A raw material sintering process for silicon carbide crystals grown by PVT method

[0036] The process steps are as follows:

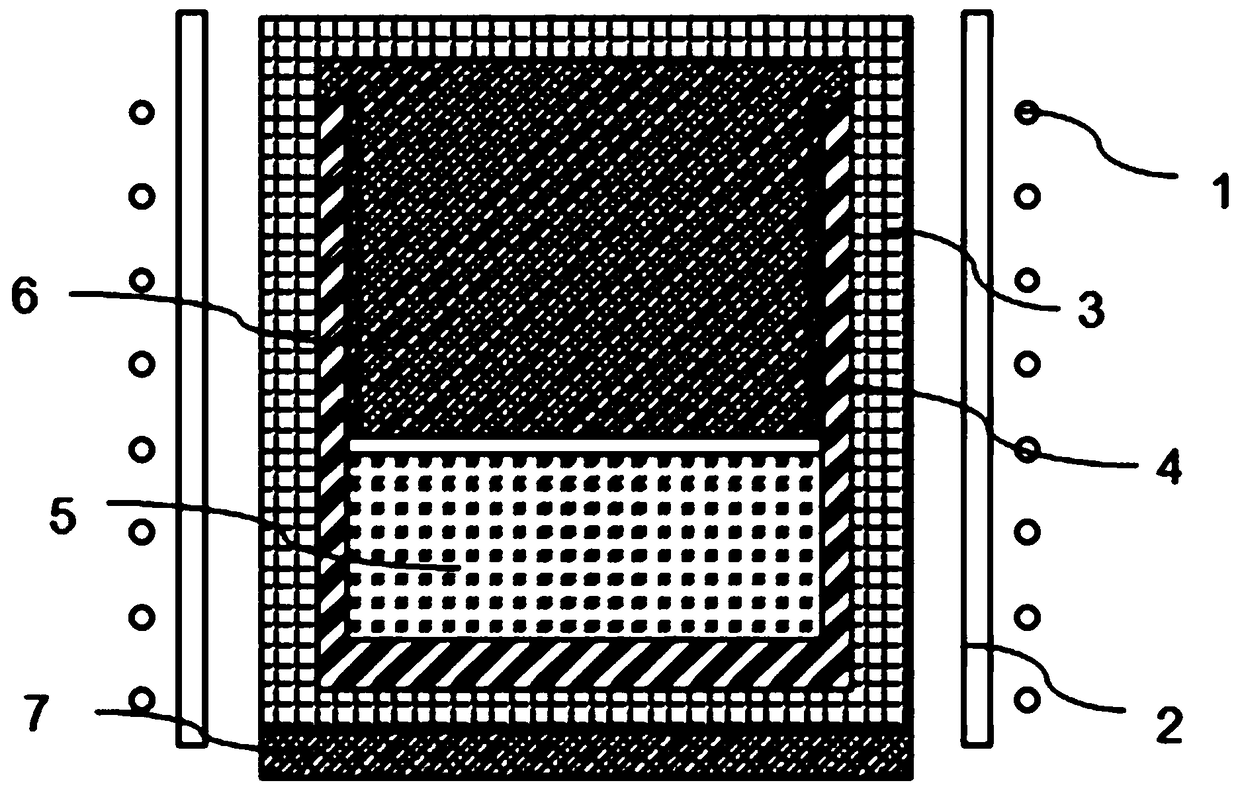

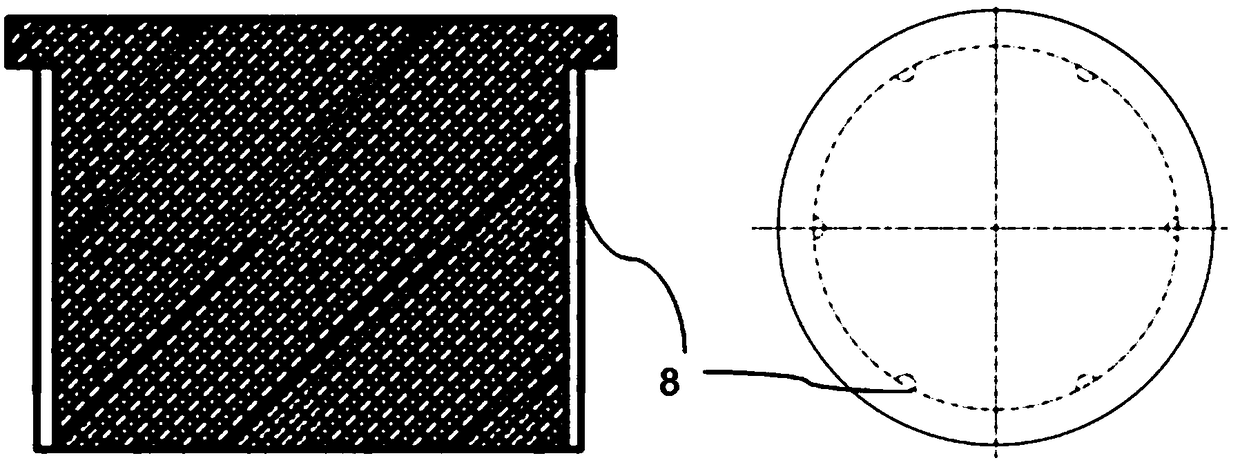

[0037] S10, put 1.0kg of silicon carbide raw material with a purity of 5N into a graphite crucible with a thickness of 5mm, flatten it, put it into a sintering fixture, the distance between the bottom of the sintering fixture and the upper surface of the silicon carbide raw material is 5mm, and wrap the outer circumference of the graphite crucible with a layer thickness 10mm thermal insulation layer;

[0038] In the above operations, the silicon carbide raw material can also be a mixture of high-purity carbon powder and silicon powder; the graphite crucible also includes a bottom heating plate made of high-density graphite with a thickness of 10mm and a diameter 10mm larger than that of the graphite crucible; IG310 with six vias.

[0039] S20, evacuate the graphite crucible to a pressure of 5x10 -2 mbar, filled with argon to control the press...

Embodiment 2

[0043] A raw material sintering process for silicon carbide crystals grown by PVT method

[0044] The process steps are as follows:

[0045] S10, put 1.4kg of silicon carbide raw material with a purity of 6N into a graphite crucible with a thickness of 20mm, flatten it, put it into a sintering fixture, the distance between the bottom of the sintering fixture and the upper surface of the silicon carbide raw material is 40mm, and wrap the graphite crucible with 4 layers of thickness 5mm heat insulation layer;

[0046] In the above operations, the silicon carbide raw material can also be a mixture of high-purity carbon powder and silicon powder; the graphite crucible also includes a bottom heating plate made of high-density graphite with a thickness of 30 mm and a diameter 100 mm larger than that of the graphite crucible; IG310 with six vias.

[0047] S20, evacuate the graphite crucible to a pressure of 4x10 -2 mbar, filled with argon gas to control the pressure at 500mbar, use ...

Embodiment 3

[0051] A raw material sintering process for silicon carbide crystals grown by PVT method

[0052] The process steps are as follows:

[0053] S10, put 1.2kg of silicon carbide raw material with a purity of 5N into a graphite crucible with a thickness of 20mm, flatten it, put it into a sintering fixture, the distance between the bottom of the sintering fixture and the upper surface of the silicon carbide raw material is 20mm, and wrap the graphite crucible with 4 layers of thickness 6mm heat insulation layer;

[0054] In the above operations, the silicon carbide raw material can also be a mixture of high-purity carbon powder and silicon powder; the graphite crucible also includes a bottom heating plate made of high-density graphite with a thickness of 20 mm and a diameter 50 mm larger than that of the graphite crucible; IG310 with six vias.

[0055] S20, evacuate the graphite crucible to a pressure of 3x10 -2 mbar, filled with argon gas to control the pressure at 200mbar, use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com