Graphite resistance heating SiC crystal growth furnace

A technology of crystal growth furnace and graphite resistor, which is applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., to achieve the effect of reducing radial temperature gradient, small radial temperature gradient and increasing length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

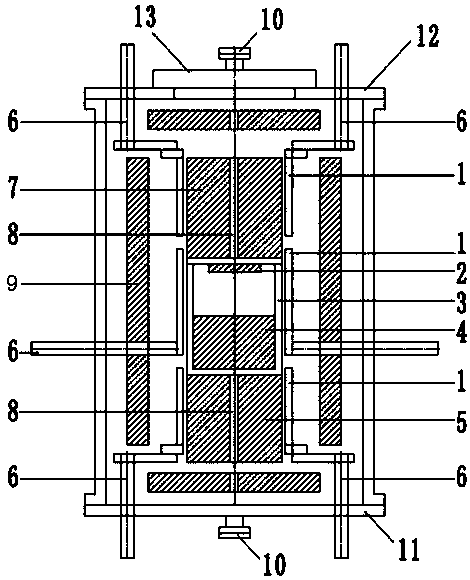

[0024] Graphite resistance heating SiC crystal growth furnace of the present invention, as figure 1 As shown, it includes a furnace cavity, a graphite crucible 3 and a graphite heating unit 1 . The furnace cavity is a double-layer stainless steel water-cooled structure, and a vacuum system, automatic control and alarm system are installed on it. The upper and lower ends of the furnace cavity are respectively provided with an upper flange cover 12 and a lower flange cover 11, the upper flange cover 12 is provided with a furnace cover 13, and the lower flange cover 11 and the upper furnace cover 13 are equipped with infrared temperature measuring devices. windows 10.

[0025] The graphite crucible 3 is arranged in the temperature field of the furnace cavity, and the upper part of the graphite crucible 3 is covered with a graphite cover (seed crystal cover), and the graphite cover is used for bonding the SiC seed crystal 2 . An upper heat-retaining graphite felt 7 and a lower h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com