Thermal field structure used in polycrystalline silicon ingot furnace for controlling crystal growth interface

A polycrystalline furnace and crystal growth technology, which is applied in the directions of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve the problems of large lateral temperature gradient, affecting the performance of cells, and poor flatness of the crystallization interface. The effect of uniform resistivity, reduction of crystal defects, and reduction of thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

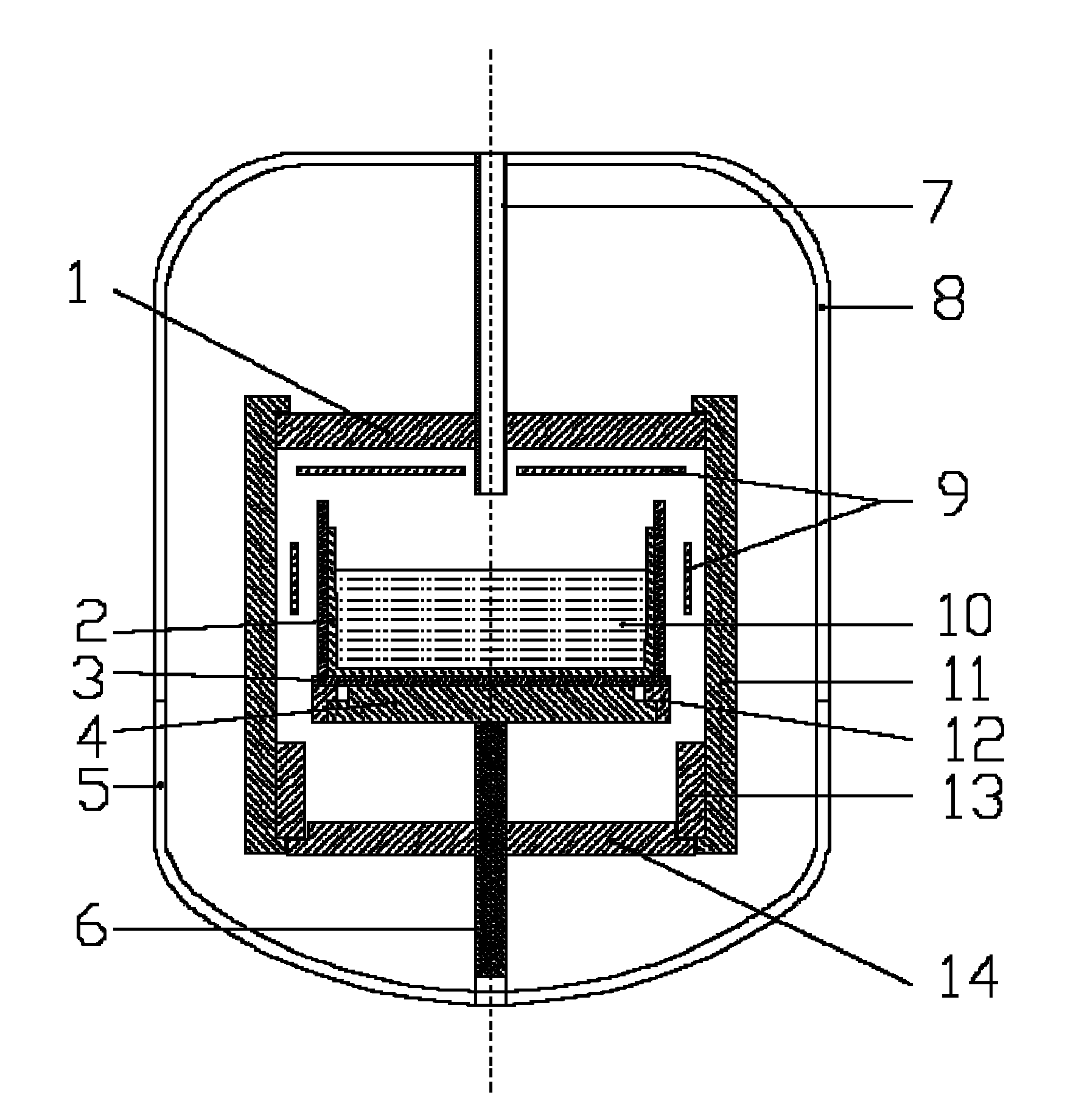

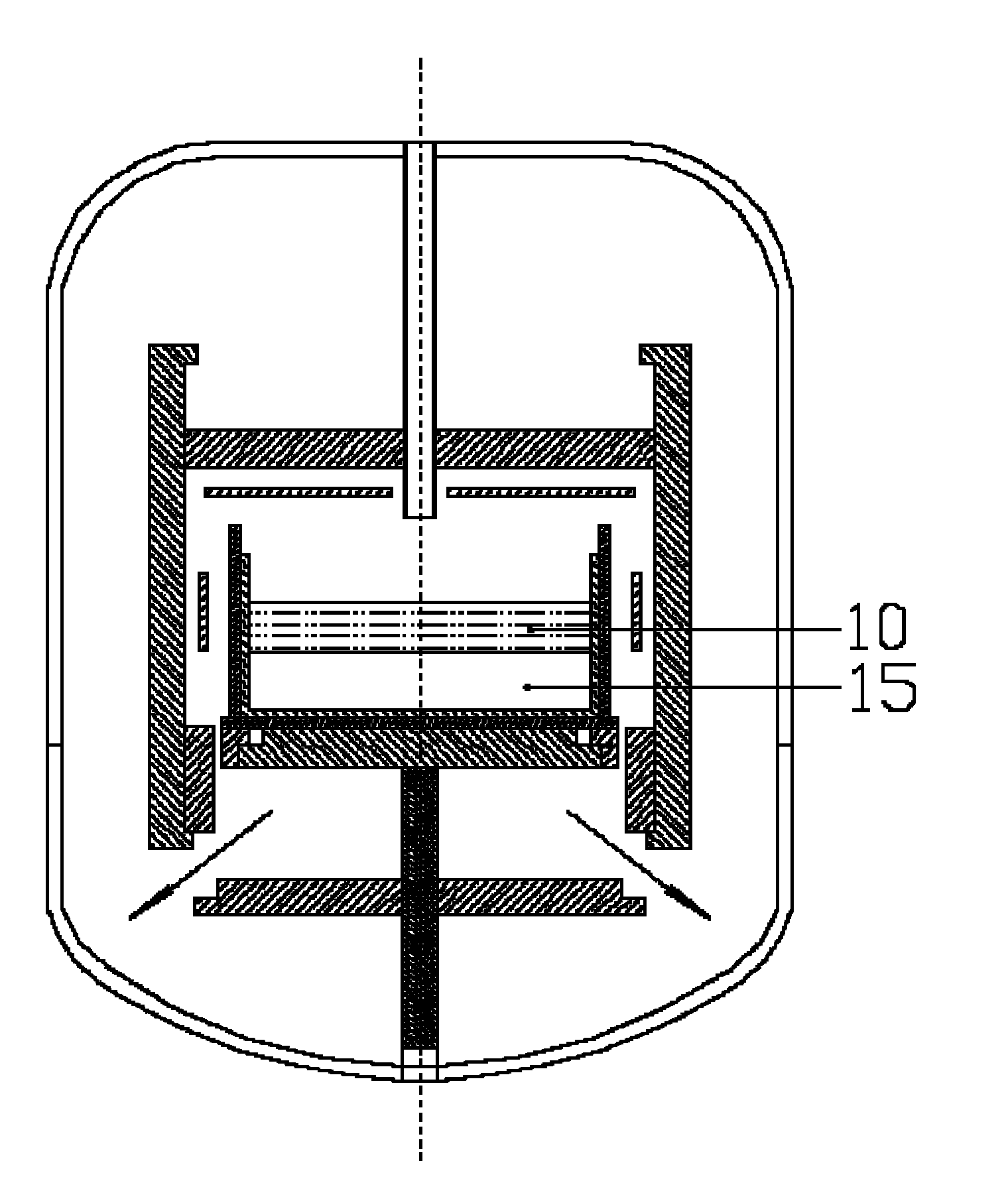

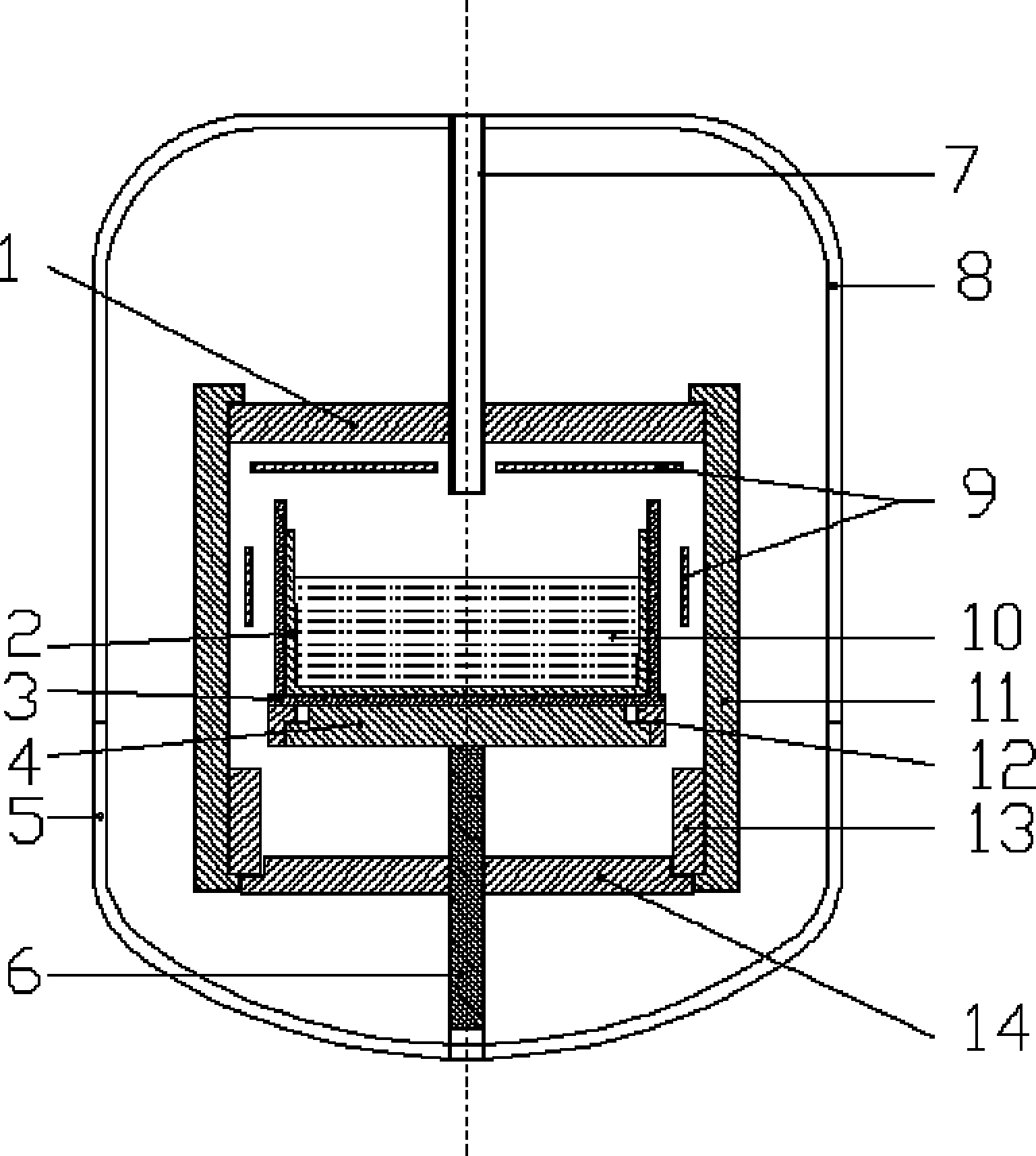

[0010] like figure 1 figure 2 The thermal field structure of a polycrystalline furnace for controlling the crystal growth interface shown has an upper furnace body 8 and a lower furnace body 5, and the upper furnace body 8 is provided with a heat insulation cage 11 and an upper insulation board 1 with an air guide cylinder 7, The lower furnace body 5 is provided with a bottom insulation board 14 supported by a support rod 6. At the same time, the support rod 6 supports the graphite coagulation aid 4 in the heat insulation cage 11, and the quartz crucible 2 is placed in the graphite crucible 3, and the graphite crucible 3 is placed On the graphite coagulation aid block 4, heaters 9 are arranged on the top and sides of the graphite crucible 3.

[0011] L-shaped heat preservation board 12 is hung upside down on the edge of both ends of graphite auxiliary clot 4, the narrow side thickness of L shape heat preservation board 12 is 20~80mm, the height of L shape heat preservation b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com