Crystal growth crucible and crystal growth furnace

A technology of crystal growth and crucible, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of easy cracking of crystals, and achieve the effect of reducing radial temperature gradient and solving easy cracking of crystals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

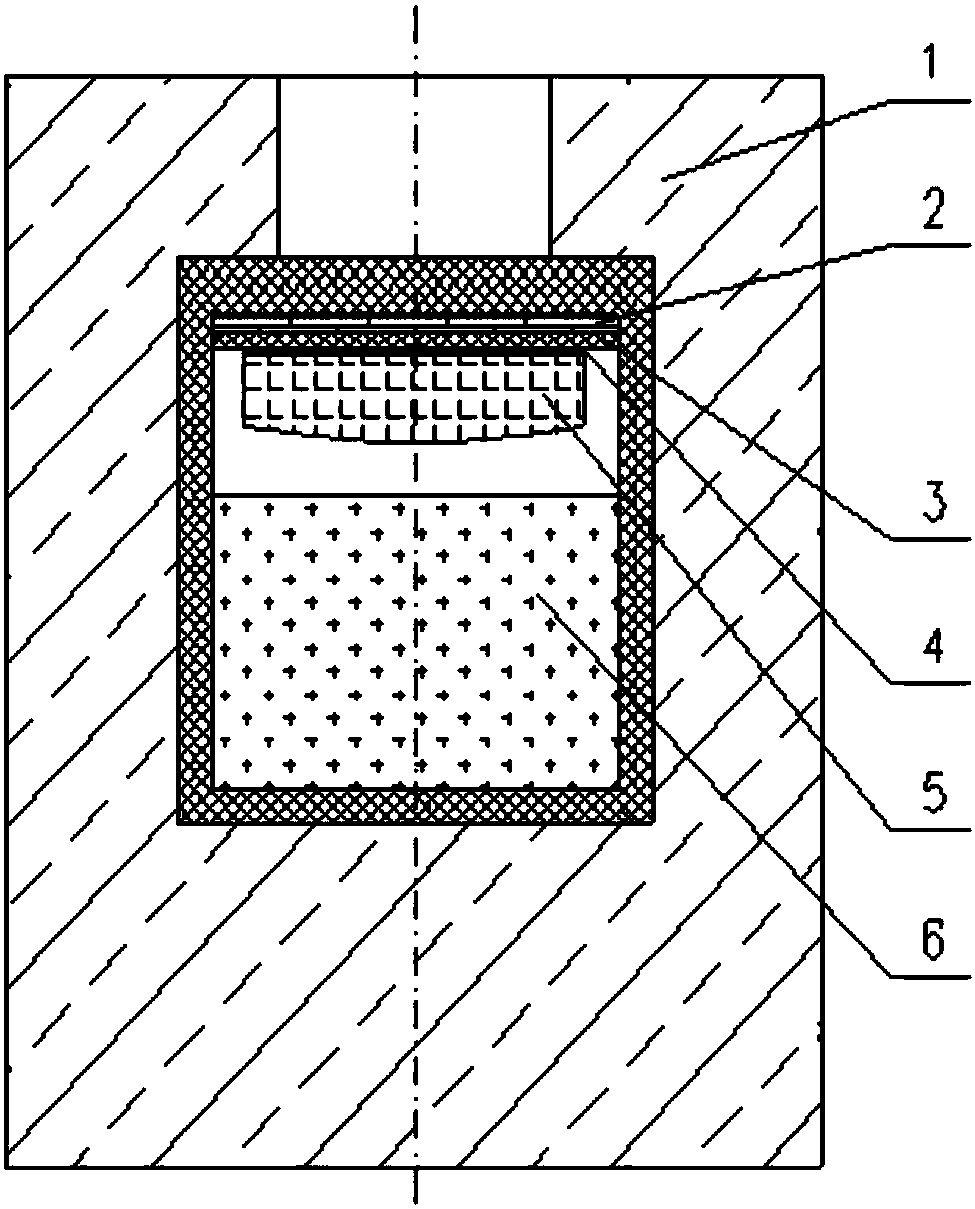

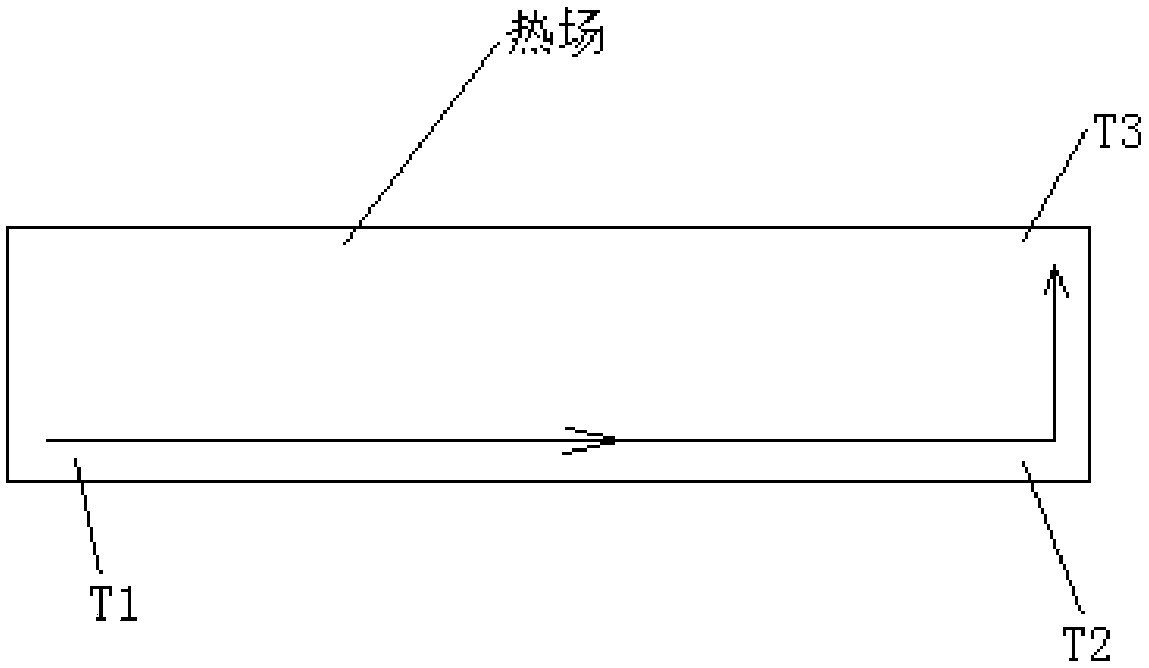

[0026] figure 1 For the structural schematic diagram of the application of the crystal growth crucible provided by the embodiment of the present invention, please refer to figure 1 , the crystal growth crucible provided by the embodiment of the present invention is provided with an installation position for fixing the seed crystal 4 on its top wall (such as figure 1 The position of the seed crystal 4), the raw material 6 for growing crystals is arranged in the crucible; a heat transfer layer 2 is also arranged on the installation position, and the thermal conductivity on the plane where the heat transfer layer 2 is located is greater than the thermal conductivity on the thickness direction, The thickness direction is along the figure 1 in the vertical direction.

[0027] In the present invention, since the thermal conductivity of the heat transfer layer 2 on its plane is greater than the thermal conductivity in its thickness direction, that is, the heat conduction effect of ...

Embodiment 2

[0041] An embodiment of the present invention provides a crystal growth furnace, including a crystal growth crucible and a heating device, the heating device is used to heat the crystal growth crucible, so that the growth environment in the crucible reaches the process temperature, and the crystal growth crucible The crystal growth crucible provided in Embodiment 1 of the present invention was used.

[0042]The crystal growth furnace provided by the embodiment of the present invention, because it adopts the crystal growth crucible provided by the above-mentioned embodiment 1, can effectively reduce the radial temperature gradient of the crystal thermal field, thereby solving the problem of crystal growth when growing large-sized crystals. Easy cracking problem.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com