Plastic extruder

A technology of plastic extruder and extrusion port, which is applied in the field of plastic extruder, can solve the problems of large radial temperature gradient and low shear rate of molten material, etc., so as to prolong the service life, reduce production cost, good corrosion resistance and The effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

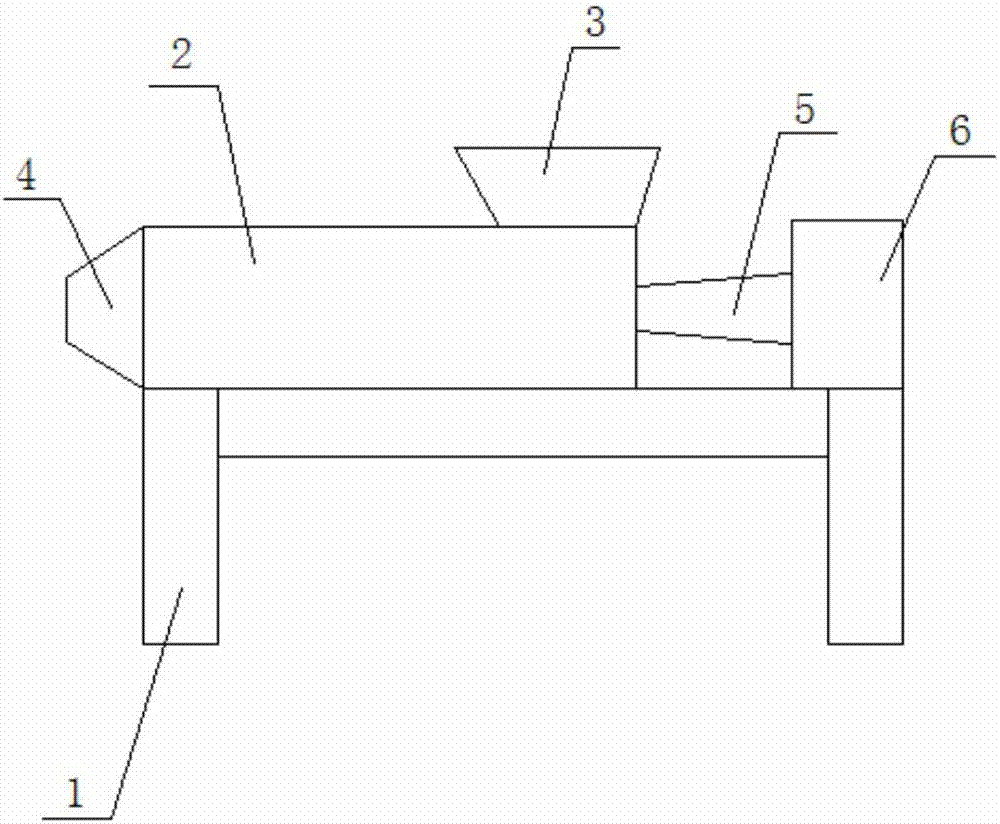

[0027] Such as Figure 1 to Figure 2 As shown, the present invention provides a plastic extruder, comprising: a base 1, a barrel 2 arranged on the base 1, a feed port 3 arranged at the top of one end of the barrel 2, an extruder arranged at the other end of the barrel 2 An outlet 4, a screw 5 arranged inside the barrel 2, a motor 6 arranged on one side of the barrel 2 and connected to the screw 5. The material enters the barrel 2 from the feed port 3, and the motor 6 drives the screw 5 to rotate, so that the material is extruded from the extrusion port 4.

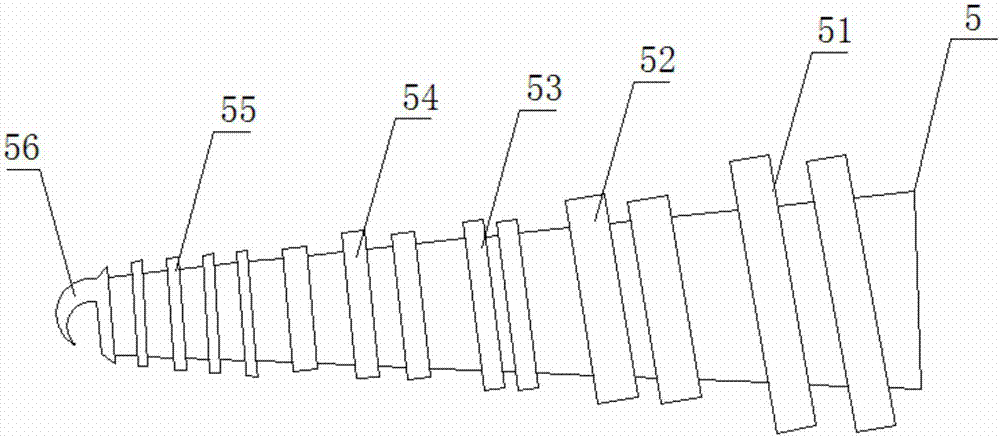

[0028] The screw 5 is a cone-shaped screw, and includes a feed section 51 , a plasticizing section 52 , a compression section 53 , an exhaust section 54 , an extrusion section 55 and a hooked screw head 56 in the direction from the motor 6 to the extrusion port 4 . The outer taper angle of the screw rod 5 is 2.46 degrees. The extrusion section 55 is of equal pitch structure, and the pitch is continuously and gradually inc...

Embodiment 2

[0030] A method for processing the screw of a plastic extruder, the steps are as follows:

[0031] ①, screw milling

[0032] 38CrMoA1 round bar is used, the blank is 150mm×1530mm, and it is processed by rough turning, semi-finishing turning, rough grinding, threading, milling back groove, turning thread groove, tempering, polishing, and fine grinding;

[0033] The screw is a cone-shaped screw, and the outer cone angle of the screw is 2.46 degrees; it includes the feeding section, the plasticizing section, the compression section, the exhaust section, the extrusion section and the hook-shaped screw head; The extrusion direction is a continuous gradual increase structure; the feeding section, plasticizing section, compression section, and exhaust section are of equal differential variable diameter and pitch structure;

[0034] ②, protective layer spraying

[0035] Spray the protective layer on the milled screw, and process it by electrostatic spraying. After the processing is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com