Micro-pulling-down crystal growing furnace

A technology of a crystal growth furnace and a seed rod, which is applied in the field of micro-pulling crystal growth furnaces, can solve the problems of uneven temperature field control, inability to accurately adjust the temperature gradient, etc., and achieve stable internal temperature field, good observation effect, Easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

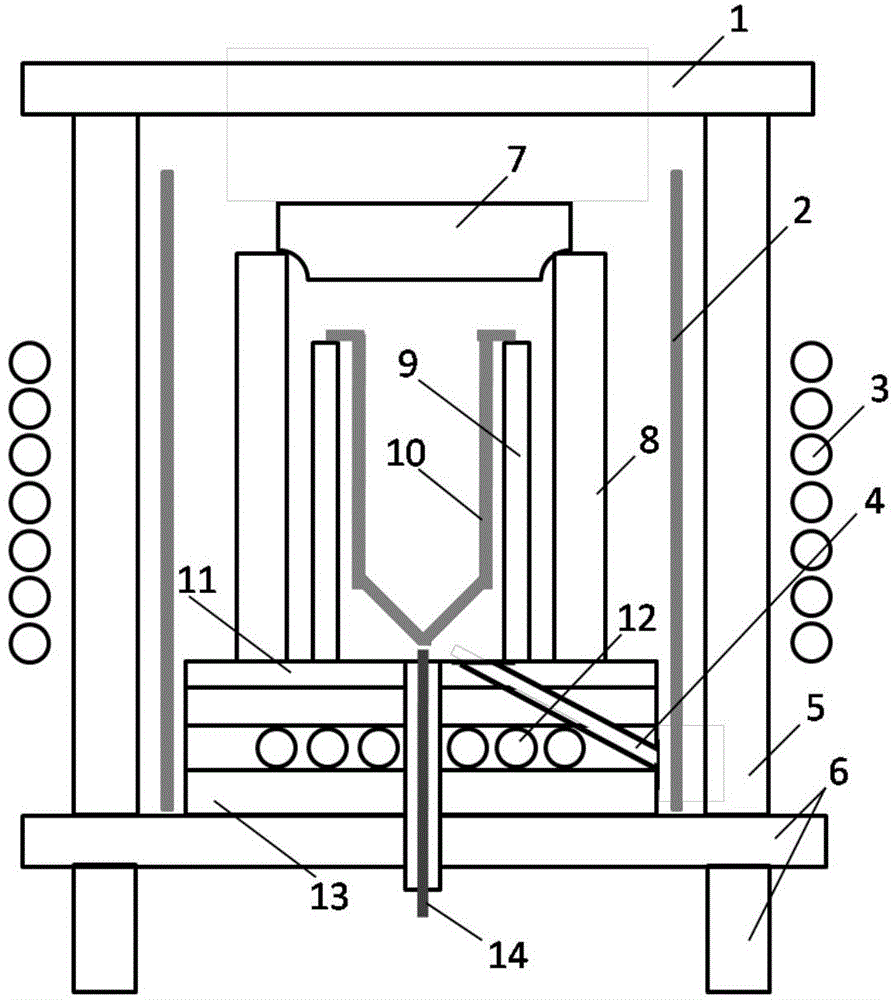

[0033] figure 1 Shown is the structure diagram of the crystal growth furnace by pulling down slightly, in which: the outer insulating cover 1 and the outer insulating wall 5 are made of asbestos, the middle insulating cover 7, the middle insulating wall 8, the inner insulating layer 9 and the bottom insulation Layer 13 is made of zirconia and aluminum oxide with a mass ratio of 1:9 by pressing and calcining. The bottom insulation support 11 is made of tungsten; the central axis of the observation hole and the normal line of the top surface of the bottom insulation layer are at 45°.

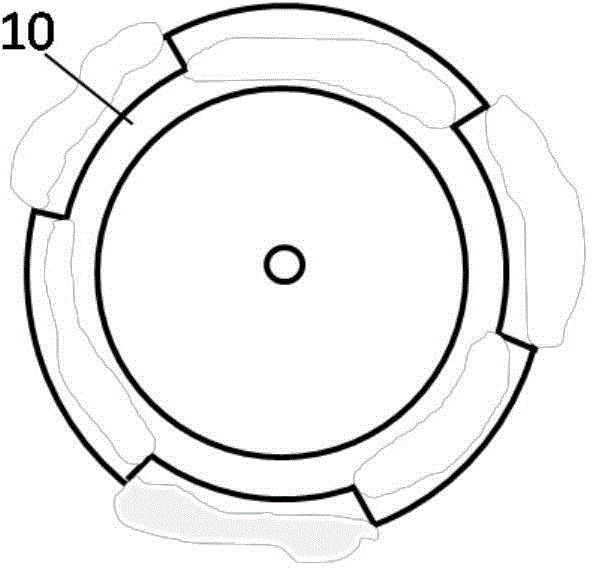

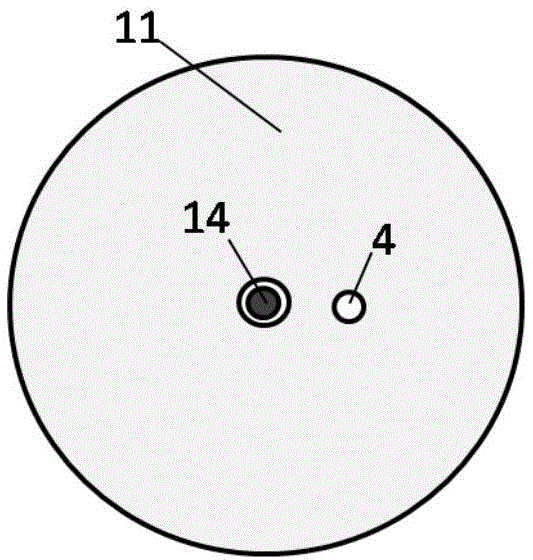

[0034] figure 2 It is the top view of the crucible, the protruding design of the upper part of the crucible can make the crucible easily supported on the inner insulation layer. image 3 A schematic top view of the bottom insulation layer.

[0035] The inner thermal insulation layer can be used to support the crucible, which requires that the material of the inner thermal insulation layer not only has ...

Embodiment 2

[0040] The arrangement of the second embodiment is basically the same as that of the first embodiment. The difference between the two is that the bottom insulation support 11 uses molybdenum, and the central axis of the observation hole is 60° with the normal line of the top surface of the bottom insulation layer.

[0041] The arrangement of multiple water cooling pipes 12 is as Figure 4 As shown, 12-A has both a cooling water input port and a cooling water output port, and the input port and the output port are intersected (for example, if the first 12-A port is the cooling water input port, the second 12-A Port A is the cooling water output port, and the third 12-A port is the cooling water input port, and so on); correspondingly, 12-B has both cooling water input and output ports.

Embodiment 3

[0043] The configuration of the third embodiment is basically the same as that of the second embodiment. The difference between the two is that the bottom insulation support 11 is made of tungsten-molybdenum alloy; and, the outer insulation layer (including the outer insulation cover 1 and the outer insulation wall 5) and the middle insulation layer are removed (Including the middle insulation cover 7 and the middle insulation wall 8), it is possible to grow crystal materials with a low melting point. At this time, the internal heat insulation layer 9 can be arranged in a position parallel to the bottom of the crucible, and 3-6 observation holes can be evenly arranged, and the observation holes can be directly observed through the quartz round tube 2. The observation window in the bottom insulation layer 13 can be closed to improve the operability of the system.

[0044] An outer shell can also be arranged outside the micro-lifting crystal growth furnace to enhance the sealing ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com