Oriented growth method of relaxor ferroelectric single crystal lead zincate niobate-lead titanate

A relaxation ferroelectric single crystal, lead niobate zincate technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of inability to directly observe the growth crystal state, small size, uncertain growth direction, etc. Achieve the effect of controllable crystal nucleation direction, high yield and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 0.93Pb(Zn 1 / 3 Nb 2 / 3 o 3 )-0.07PbTiO 3 Crystal preparation

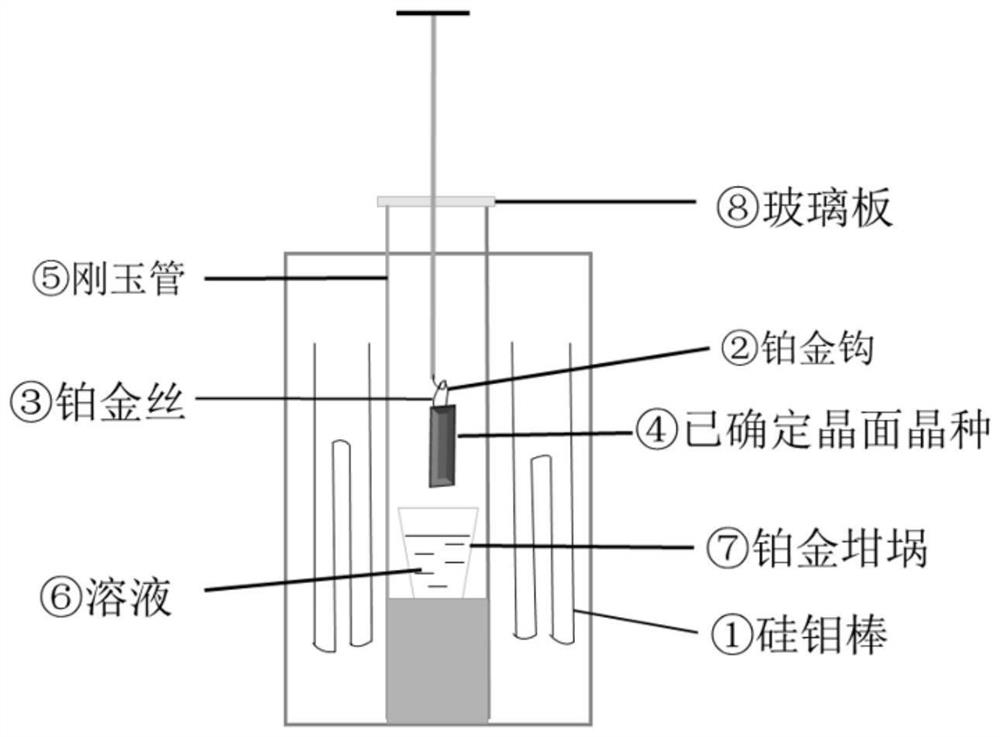

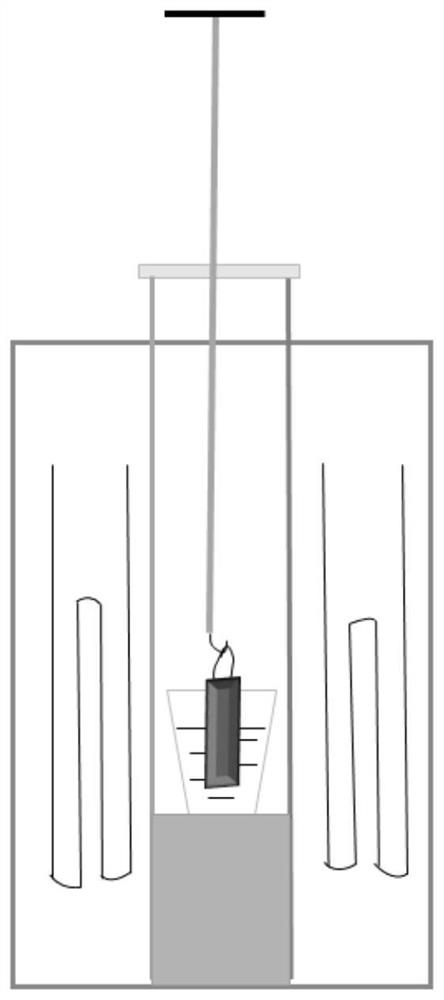

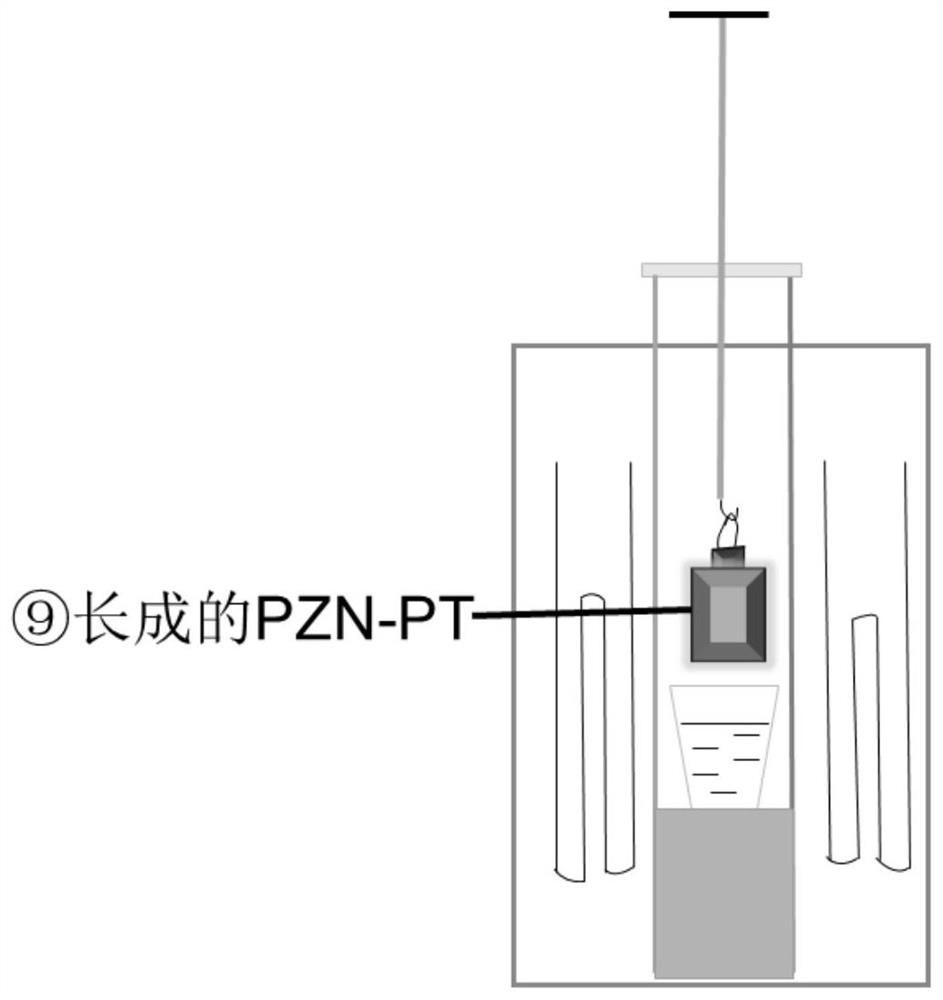

[0024] The initial raw materials PbO, ZnO, Nb 2 o 3 、TiO 2 According to 0.93Pb(Zn 1 / 3 Nb 2 / 3 o 3 )-0.07PbTiO 3 The chemical composition of the mixture was weighed and mixed uniformly, ground for 2 hours, and initially calcined at 850°C for 4 hours. Then continue to grind the powder after initial calcining for 2 hours, and put it into a tube furnace for secondary calcining at 950°C for 4 hours to obtain 0.93Pb(Zn 1 / 3 Nb 2 / 3 o 3 )-0.07PbTiO 3 For the polycrystalline powder, take out the powder that has been calcined twice, and then add PbO in the same amount as the polycrystalline powder as a cosolvent, and continue to fully grind for 2 hours. Put the above-mentioned mixed material into a platinum crucible, put it in a furnace, first raise the temperature to 1200°C to melt the mixed material into a solution, and then cool down to start growing crystals (such as figure 1 shown), when the ...

Embodiment 2

[0025] Example 2 0.96Pb(Zn 1 / 3 Nb 2 / 3 o 3 )-0.04PbTiO 3 Crystal preparation

[0026] The initial raw materials PbO, ZnO, Nb 2 o 3 、TiO 2 According to 0.96Pb(Zn 1 / 3 Nb 2 / 3 o 3 )-0.04PbTiO 3 The chemical composition of the mixture was weighed and mixed uniformly, ground for 2 hours, and initially calcined at 880°C for 4 hours. Then continue to grind the powder after initial calcining for 2 hours, and put it into a tube furnace for secondary calcining at 950°C for 6 hours to obtain 0.96Pb(Zn 1 / 3 Nb 2 / 3 o 3 )-0.04PbTiO 3 For the polycrystalline powder, take out the pre-fired powder for the second time, then add the same amount of PbO as the polycrystalline powder as a cosolvent, and continue to fully grind for 2 hours. Put the above-mentioned mixture into a platinum crucible, put it in a furnace, first raise the temperature to 1200°C to melt the mixture into a solution, and then cool down to start growing crystals. At 1078°C, add lead-titanium niobate zincate with a ...

Embodiment 3

[0027] Example 3 0.98Pb(Zn 1 / 3 Nb 2 / 3 o 3 )-0.02PbTiO 3 Crystal preparation

[0028] The initial raw materials PbO, ZnO, Nb 2 o 3 、TiO 2 According to 0.98Pb(Zn 1 / 3 Nb 2 / 3 o 3 )-0.02PbTiO 3 The chemical composition of the mixture was weighed and mixed uniformly, ground for 2 hours, and initially calcined at 850°C for 4 hours. Then continue to grind the powder after initial calcining for 2 hours, and put it into a tube furnace for secondary calcining at 960°C for 4 hours to obtain 0.98Pb(Zn 1 / 3 Nb 2 / 3 o 3 )-0.02PbTiO 3 For the polycrystalline powder, take out the powder that has been calcined twice, and then add PbO in the same amount as the polycrystalline powder as a cosolvent, and continue to fully grind for 2 hours. Put the above-mentioned mixture into a platinum crucible, put it in a furnace, first raise the temperature to 1200°C to melt the mixture into a solution, then cool down to start growing crystals, and at 1080°C, add lead-titanium niobate zincate whos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com