Single crystal furnace for achieving rapid crystal growth through chemical heat sink enhanced cooling technology

A technology of chemical heat sink and single crystal furnace, applied in crystal growth, single crystal growth, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings.

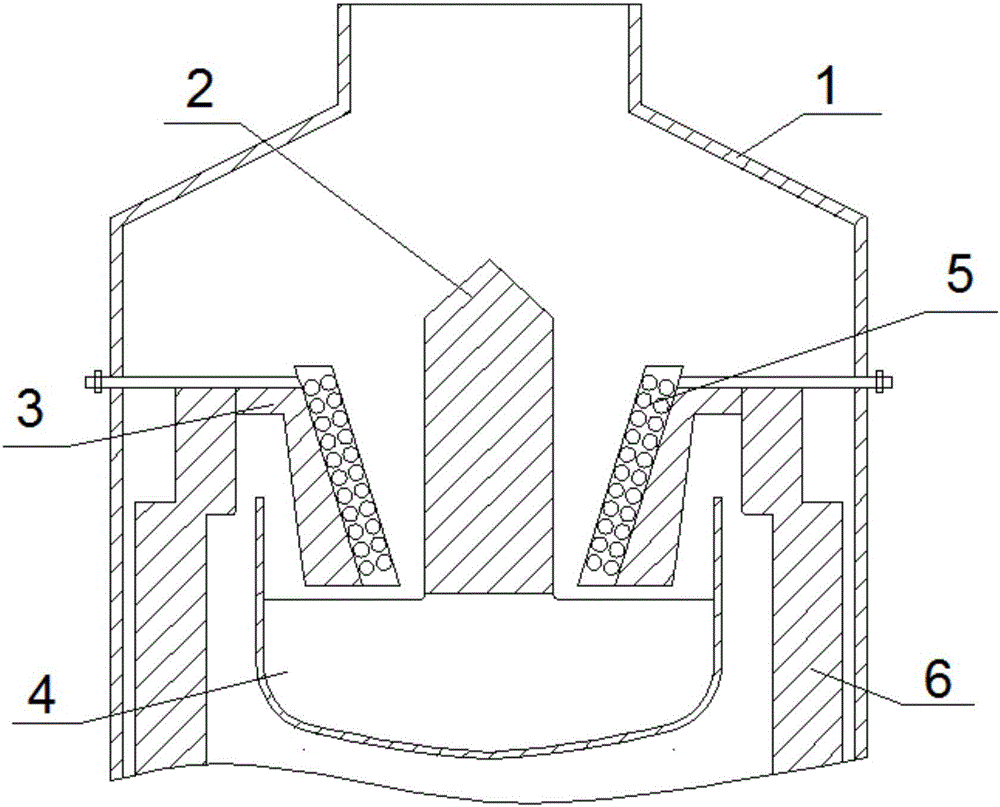

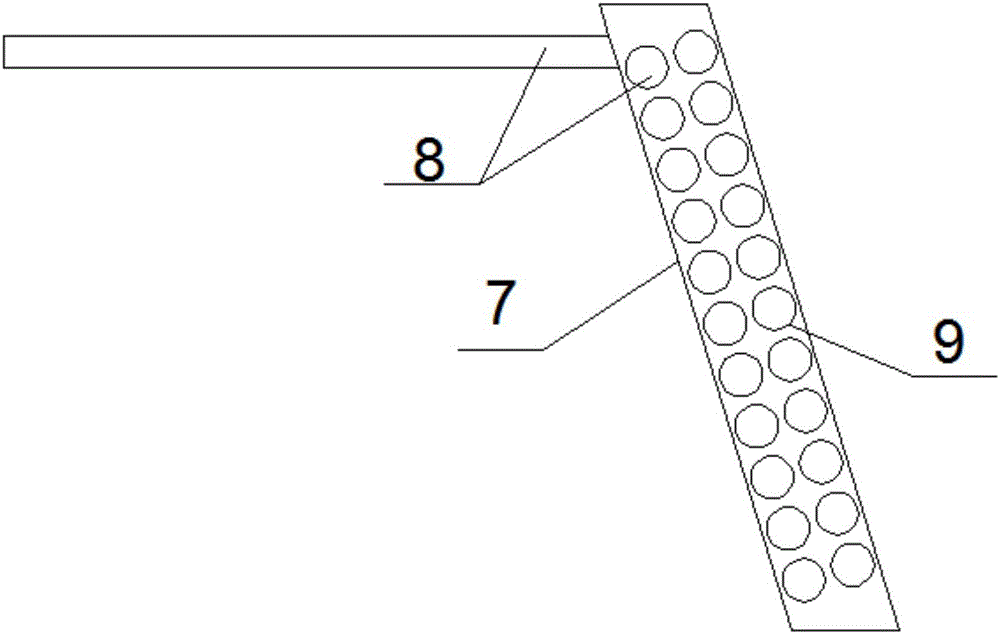

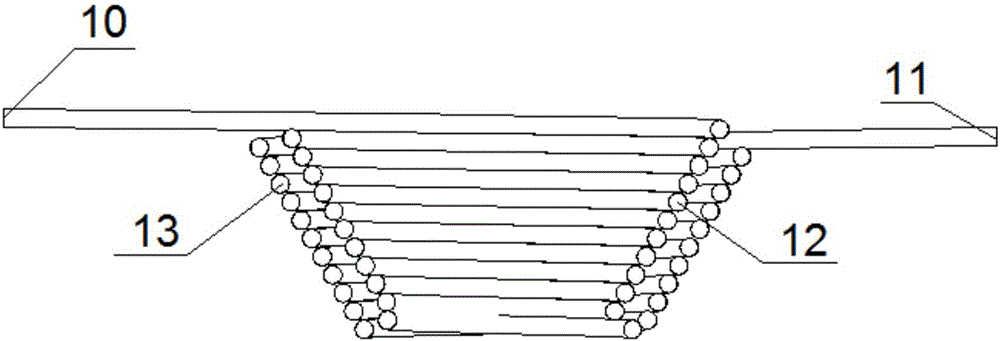

[0034] like Figure 1-4 As shown, the single crystal furnace that realizes rapid crystal growth through chemical heat sink enhanced cooling technology mainly involves a reaction device 5 that transports reactants and performs chemical endothermic reaction inside. The reaction device 5 is composed of two parts with a taper, and the combined parts are a truncated hollow graphite tube 7 and a reaction tube 8 providing a chemical reaction place. The reaction tube 8 is placed inside the graphite tube 7, and the flow of gas in the vicinity of the crystal can be stabilized. The taper of the graphite cylinder 7 is 0°-60°, the distance between the lower end face and the crystal 2 is 10-40mm, and the distance from the melt 4 is 10-40mm. The reaction cylinder 8 is surrounded by a hollow spiral coil 9, two ends of which extend out of the furnace body 1, one end is the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com