A high-quality silicon carbide single crystal, substrate and efficient preparation method thereof

A silicon carbide single crystal, high-quality technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve problems such as difficult radial temperature gradient, axial temperature gradient drop, small radial temperature gradient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

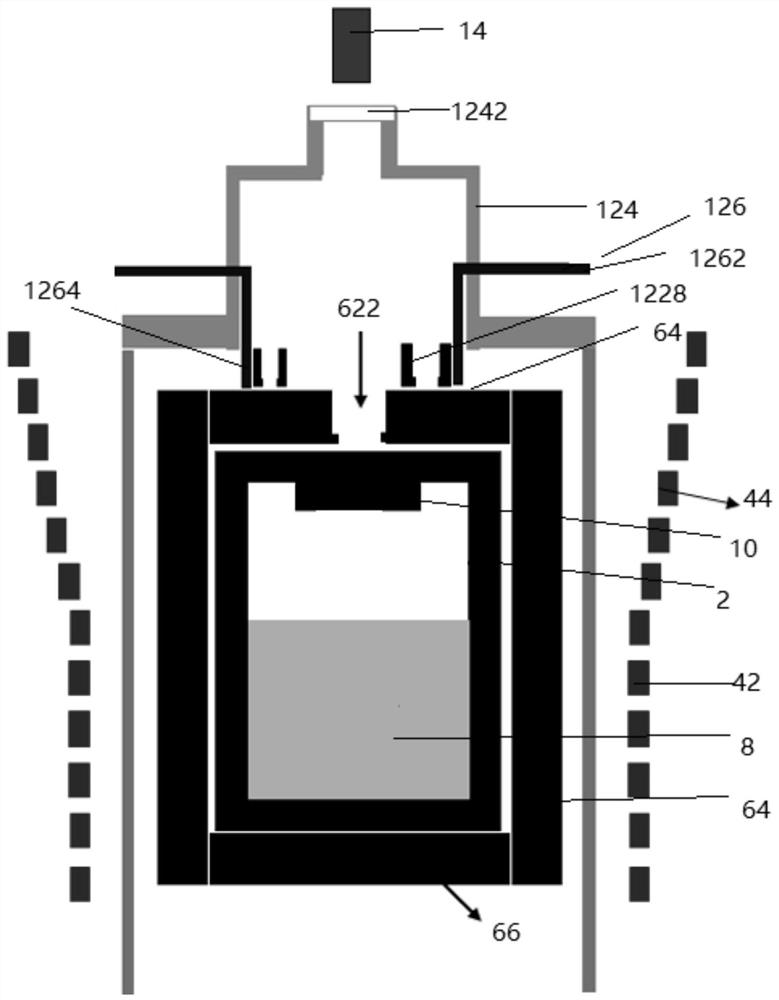

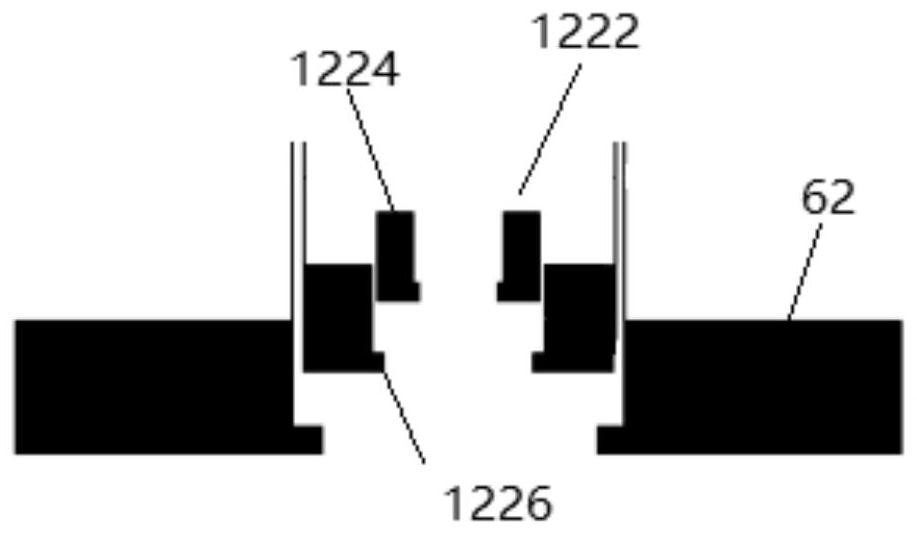

[0102] refer to figure 1 and 2 , the embodiment of the application discloses a device for preparing single crystal, refer to figure 1 . The device for preparing a single crystal includes a crucible 2, a heating coil group and a heat preservation structure. The crucible 2 forms a growth chamber, and the growth chamber includes a raw material area for accommodating raw materials 8 and a crystal growth area for setting a seed crystal 10. The heating coil group surrounds the crucible 2. The side wall is arranged, and the heating coil group includes a first coil group 42 arranged corresponding to the height of the raw material area and a second coil group 44 arranged corresponding to the height of the crystal growth area. Along the direction from the raw material 8 to the seed crystal 10, the second coil The inner diameter of the set 44 is increased. The diameter of the coil increases from the raw material 8 upward, thereby reducing the temperature at the seed crystal 10. Compar...

Embodiment 2

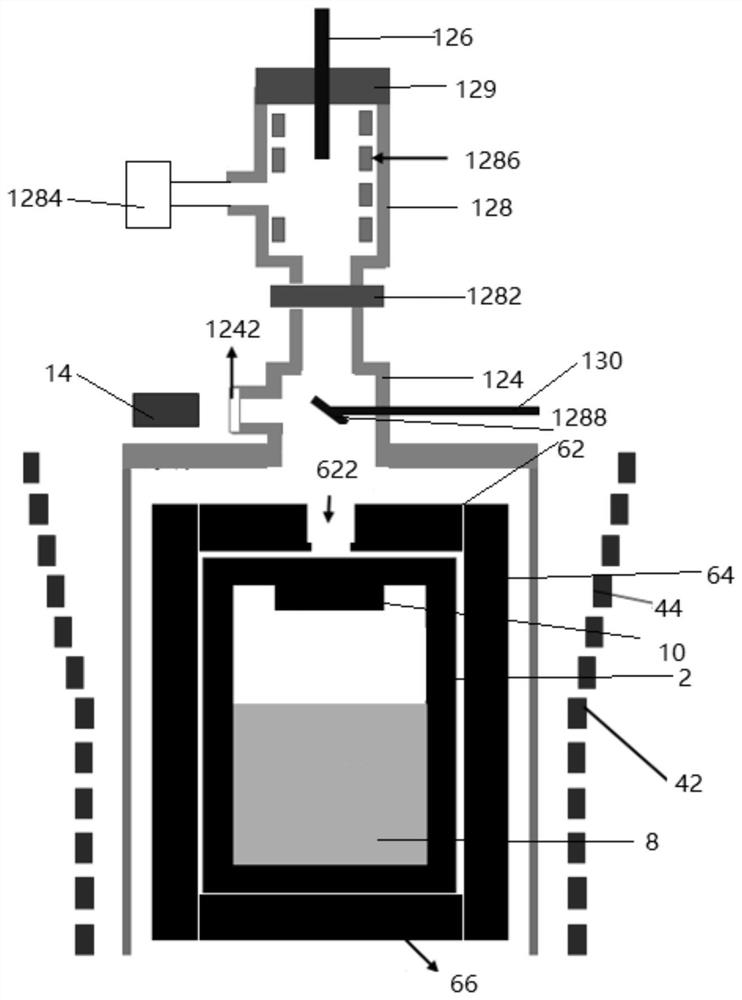

[0120] refer to image 3 The difference between this embodiment and the device for preparing a single crystal in Example 1 is that the adjustment mechanism is different, and the adjustment mechanism also includes a buffer chamber 128 .

[0121] Specifically, the buffer chamber 128 is arranged above the regulating chamber 124, and a first valve 1282 is arranged between the buffer chamber 128 and the regulating chamber 124; The temperature of the chamber is the same as that of the ambient gas. The first conveying mechanism 126 is set as a manipulator, and after the manipulator transports the thermal insulation ring 1222 obtained to the buffer chamber 128, when the temperature of the thermal insulation ring 1222 is the same as the temperature of the adjustment chamber 124, the first valve 1282 is opened, and the mechanical arm places the thermal insulation ring 1222 In the temperature measurement hole 622 ; the quartz window 1242 is set on the side wall of the adjustment chamber...

Embodiment 3

[0126] Unless otherwise specified, the raw materials 8 in the examples of the present application were all purchased through commercial channels.

[0127] Analytic method is as follows in the embodiment of the application:

[0128] 1. The void defect test adopts the BX51 microscope of OLYMPUS company.

[0129] 2. MicroProf@TTV200 automatic surface tester of FRT Company is used for surface test of silicon carbide single crystal substrate.

[0130] Unless otherwise specified, the raw materials 8 and gases in the examples of the present application are purchased from commercial sources, wherein the purity of the silicon carbide raw material 8 is 99.99%, and the purity of the high-purity inert gas (Ar or He) is greater than 99.999%.

[0131] Using the crystal growth device of any of the above embodiments to grow a silicon carbide single crystal, the method for preparing a silicon carbide single crystal includes the following steps:

[0132] 1) Put the silicon carbide powder on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com