A kind of preparation method and growth device of n-type silicon carbide crystal

A growth device and a technology of silicon carbide, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve problems affecting the application and development of silicon carbide crystal performance, high dislocation density of silicon carbide substrate, etc., to ensure crystal Effects of growth rate, reduced radial temperature gradient, and reduced dislocation concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

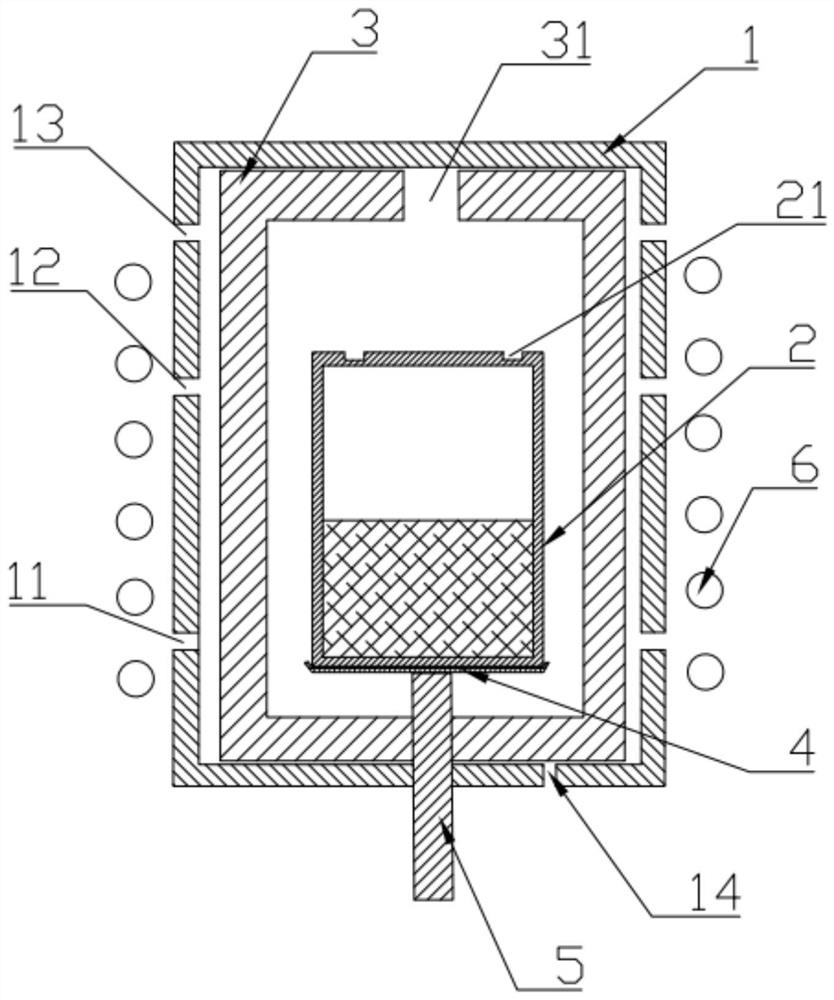

[0062] refer to Figure 1-3 , this embodiment provides a device for growing N-type silicon carbide crystal, the device includes a furnace body 1 and a crucible 2, the furnace body 1 is provided with ventilation holes, the crucible 2 is set in the furnace body 1; the top of the crucible 2 The outer wall is recessed inward to form an annular air groove 21 , and the center of the annular air groove 21 coincides with the center of the top of the crucible 2 . The arrangement of the annular air groove 21 enables the gas to flow along the annular air groove 21, the air flow rate is fast, and the gas diffuses into the crucible, so that the heat transfer in the crucible 2 away from the central axis is accelerated, and the radial temperature gradient of the crucible is reduced, thereby reducing the Dislocation defects in silicon carbide crystals are eliminated, and the quality of crystal growth is improved.

[0063] Specifically, the structure of the crucible 2 is not specifically limi...

Embodiment 2

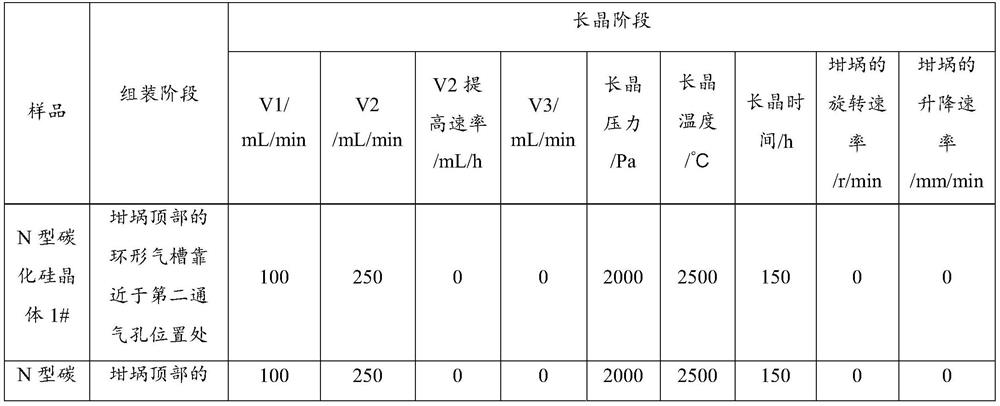

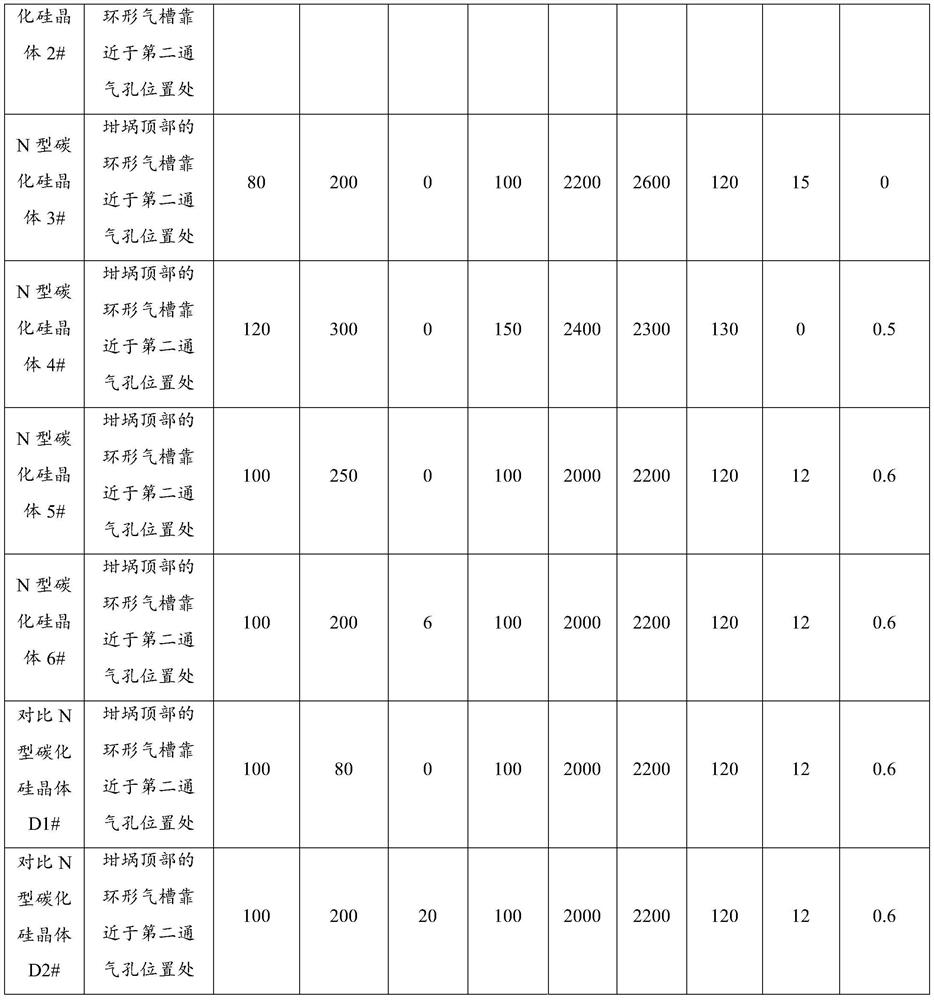

[0078] A method for growing N-type silicon carbide crystals using the device described in Embodiment 1, specifically comprising the following steps:

[0079] (1) assembly stage: silicon raw material and carbon raw material are placed in the high temperature zone of the crucible, and the seed crystal is placed in the low temperature zone of the crucible; the assembled crucible is placed in the furnace body of the crystal growth furnace;

[0080] (2) Heating stage: adjust the temperature of the crystal growth furnace to increase the temperature from 500 to 2000 °C, and control the pressure in the crucible from 0.2×10 5 Pa rises to 5×10 5 Pa, marked V1 is the flow rate of the inert gas passed into the first vent hole, V2 is the flow rate of the nitrogen source gas passed through the second vent hole, V3 is the flow rate of the nitrogen source gas passed through the third vent hole; The flow rate of the gas is 200mL / min, and the flow rate of the nitrogen source gas from V3 or V2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com