Guide cylinder and preparation method thereof

A guide tube and production method technology, applied in chemical instruments and methods, self-melting liquid pulling method, crystal growth, etc., can solve the problems of poor heat preservation effect, short service life, and many consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

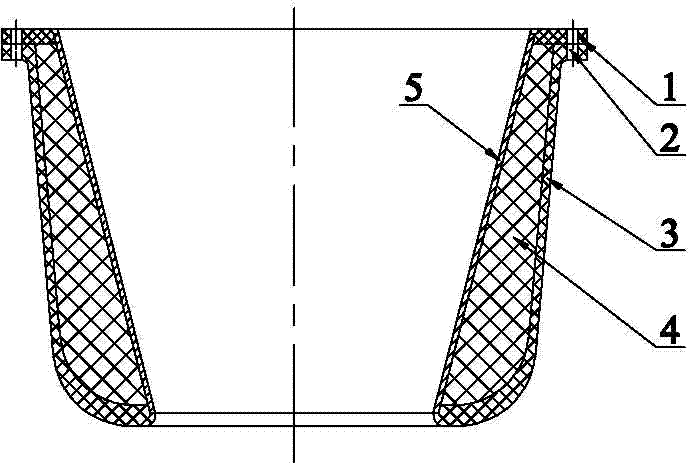

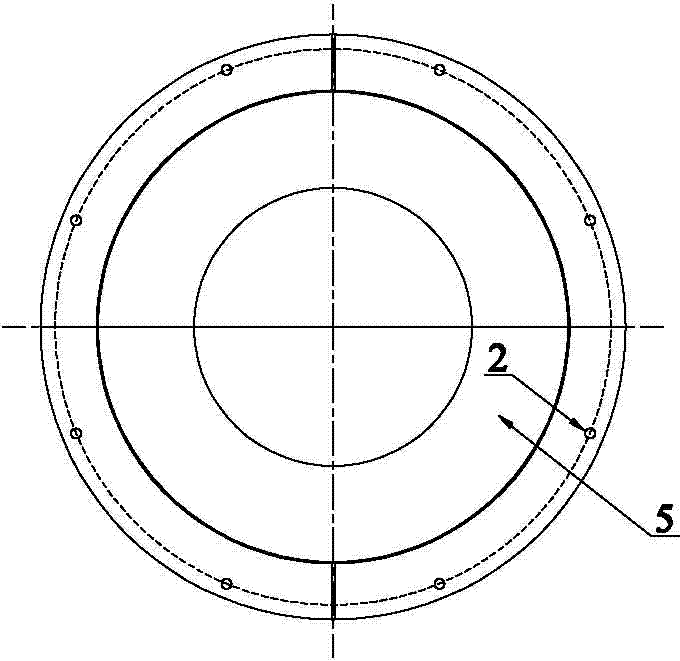

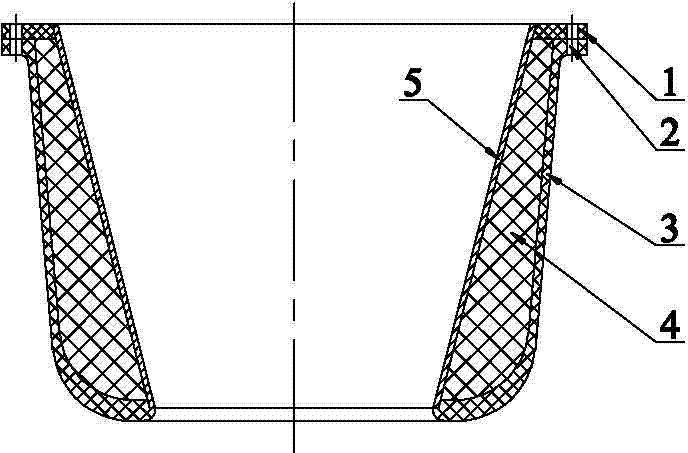

[0034] Depend on figure 1 , figure 2 It can be seen that a guide tube includes an inverted cone cylinder, and the cylinder includes an outer screen 3 and an inner screen 5, and an insulating layer 4 is provided between the outer screen 3 and the inner screen 5. The outer screen 3 is made of carbon / carbon composite material, and the inner screen 5 is made of metal molybdenum or metal tungsten (molybdenum metal is used in this embodiment); the outer screen 3 is connected with the outer screen 3 , the positioning disc 1 covered by the inner screen 5 and the insulation layer 4, so that the outer screen 3, the inner screen 5, the insulation layer 4 and the positioning disc 1 form an integral structure.

[0035] The thickness of the inner screen 5 according to the present invention is 0.5㎜~1.5㎜ (0.8㎜ in this embodiment); the positioning plate 1 is a multi-lobe structure (a two-lobe structure evenly divided in this embodiment), and graphite or Made of carbon / carbon composite mater...

Embodiment 2

[0042] The positioning plate 1 of the present invention has a multi-lobed structure (this embodiment is a two-lobed structure), made of graphite, with a thickness of 5 mm to 15 mm (10 mm in this embodiment), and a density of 1.7 g / ㎝ 3 ~2.0g / ㎝ 3 (This embodiment is 1.8g / ㎝ 3 ).

[0043] A kind of preparation method of above-mentioned guide cylinder, it adopts density as 1.7g / ㎝ in step (1) in positioning disc 1 3 ~2.0g / ㎝ 3 (This embodiment is 1.8g / ㎝ 3 ) graphite material is machined according to the required size, and the thickness is 5 mm to 15 mm (10 mm in this embodiment); The positioning plate 1 is prepared by step (1) and connected with the outer screen 3 through fasteners, so that the positioning plate 1 covers the outer screen 3, the insulation layer 4, and the inner screen 5 to form a tight whole.

[0044] The rest are the same as embodiment 1.

Embodiment 3

[0046] The inner screen 5 of the present invention is made of metal molybdenum or metal tungsten (the metal tungsten used in this embodiment); the positioning plate 1 is made of graphite, with a thickness of 5mm-15mm (this embodiment 10㎜), the density is 1.7g / ㎝ 3 ~2.0g / ㎝ 3 (This embodiment is 1.8g / ㎝ 3 ); said insulation layer 4 has a density of 0.1g / ㎝ 3 ~0.5g / ㎝ 3 (0.25 g / ㎝ in this example 3 ) of cured felt or polyacrylonitrile-based carbon felt (this embodiment is cured felt).

[0047] The rest are the same as in embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com