A kind of high-quality silicon carbide crystal and its growth method and device

A technology of crystal growth and crystal growth, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of many uncontrollable factors, unstable temperature field in the crucible, uncontrollable temperature gradient, etc., to ensure the growth efficiency , the effect of shortening the growth cycle and preventing the appearance of crystal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

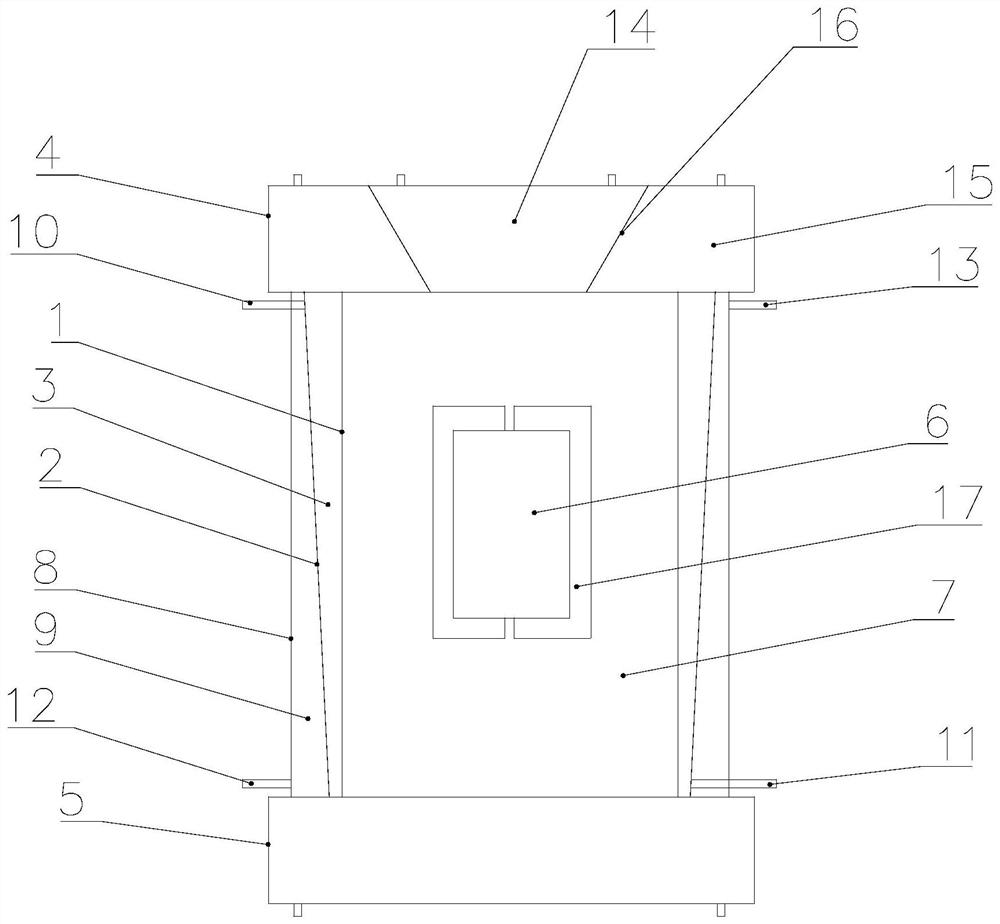

[0089] like figure 1 As shown, the embodiment of the present application discloses a crystal growth apparatus, which includes: a cooling jacket, a closed accommodating cavity 7 is formed by the components including the cooling jacket, and used for placing the crucible 6 for crystal growth; the cooling jacket It includes a first cooling pipe 1 and a second cooling pipe 2. The first cooling pipe 1 is sleeved inside the second cooling pipe 2 and cooperates with each other to form a first interlayer 3 for passing the first cooling water. The thickness of the interlayer 3 increases linearly along the direction from the bottom of the crucible 6 to the opening. By setting the thickness of the first interlayer 3 to increase linearly along the direction from the bottom of the crucible 6 to the opening, the first interlayer 3 is used to pass the first cooling water, the cross-sectional area of the first interlayer 3 increases linearly from the bottom of the crucible 6 to the opening, ...

Embodiment 2

[0112] Unless otherwise specified, the raw materials and gases in the examples of the present application are purchased through commercial channels. Among them, the purity of the silicon carbide raw material is 99.99%, and the purity of the high-purity inert gas (Ar or He) is greater than 99.999%.

[0113] Use the crystal growth device of Embodiment 1 to grow silicon carbide crystals, and the preparation method of silicon carbide crystals includes the following steps:

[0114] 1) Assemble: Assemble the cooling jacket and the flange structure to form the accommodating cavity 7, place the silicon carbide powder on the bottom of the crucible 6, place the silicon carbide seed crystal on the inner side wall of the crucible 6 cover, assemble the crucible 6 and the thermal insulation structure 17, The heat preservation structure 17 is arranged outside the crucible 6, and the assembled heat preservation structure 17 and the crucible 6 are placed in the accommodating cavity 7;

[0115...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com