Patents

Literature

152results about How to "Avoid temperature effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric pressure cooker

InactiveCN100496350CSimple structureLow costCooking-vessel materialsElectric heatingElectricityEngineering

The present invention relates to a kind of electric pressure cooker and electric rice cooker. It includes outer shell, pot cover, inner pot, heating disk and temperature detection and control device of electric heating pot. The inner pot is placed in the upper portion of heating disk, and said inner pot is a stainless steel single-layer structure. The temperature detection and control device of invented electroheating pot is formed from heat sensing element and control circuit of electroheating pot, and said heat sensing element is fixed on the heating disk.

Owner:关国华

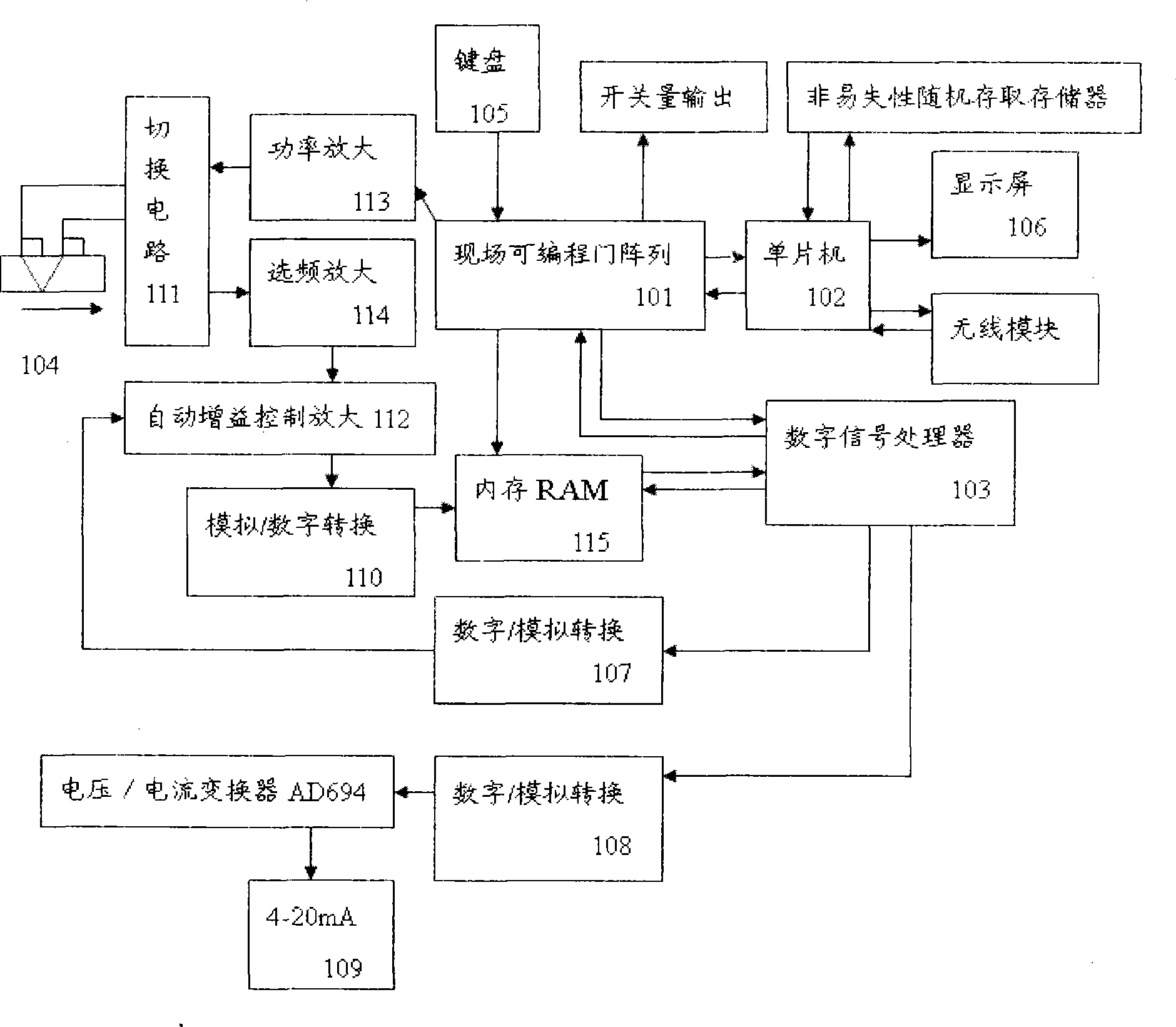

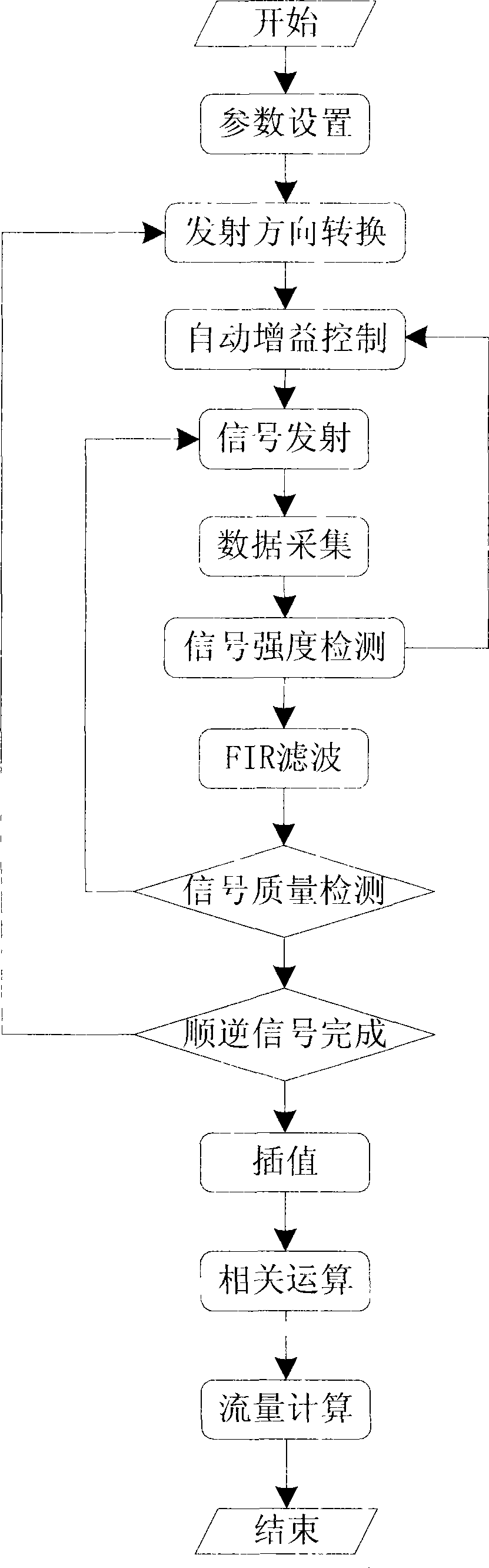

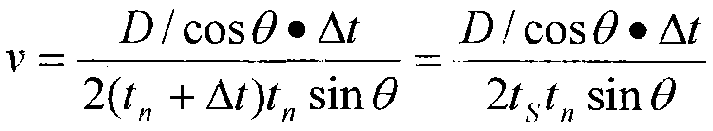

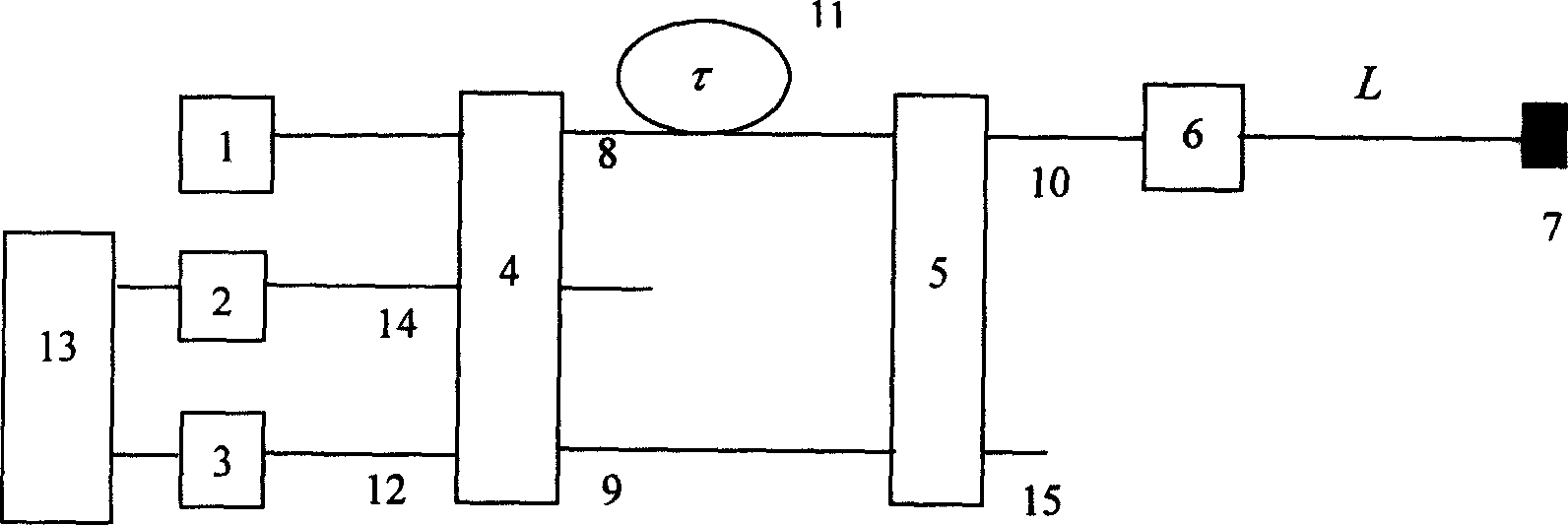

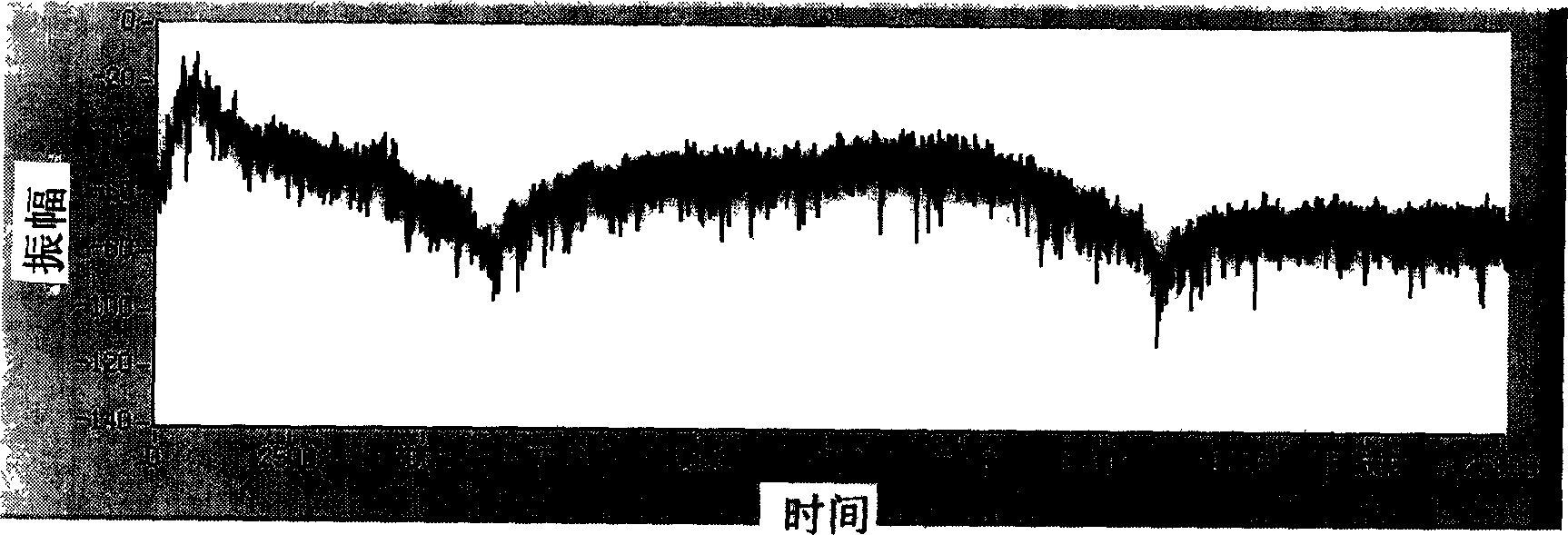

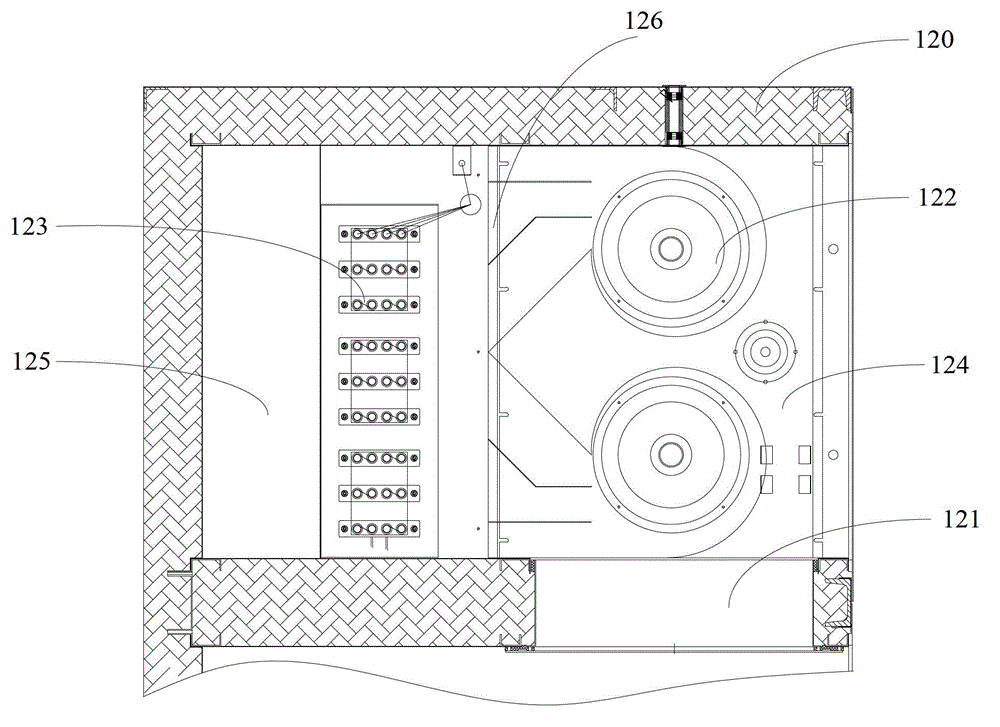

Ultrasonic flux detection system and detection method

InactiveCN101464171AHigh precisionImprove accuracyVolume/mass flow measurementCorrelation coefficientImage resolution

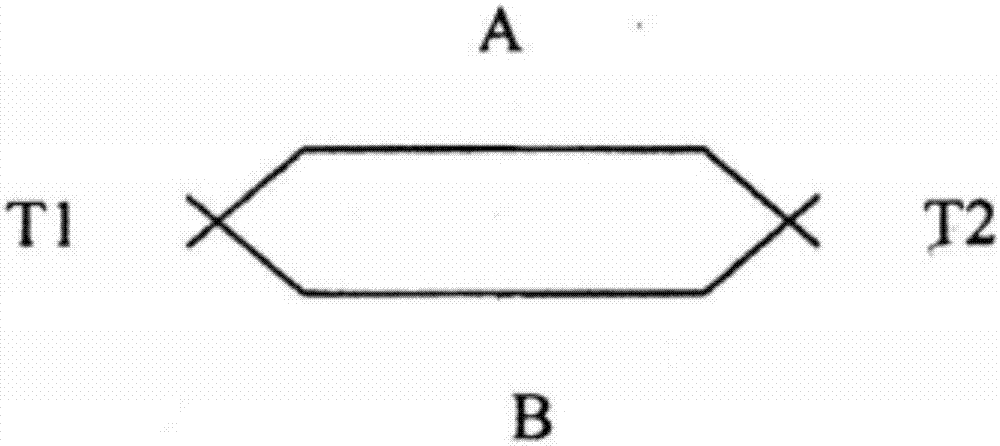

The invention belongs to the detection field, and relates to an ultrasonic wave flow rate detecting system and a detecting method, in particular to a high-precision fluid flow rate ultrasonic wave detecting system and a detecting method. The ultrasonic wave flow rate detecting system includes a system control part, a circuit part and an auxiliary device. The ultrasonic wave flow rate detecting method is characterized in that an improved time difference method is adopted for calculating the speed of a fluid; the delay window reception technique is adopted, and the influence of noise on the detection precision during detection is reduced through pulse width detection; and as the resolution of measuring time for the system is further improved through the adoption of the interpolation correlation method and the correlation coefficient judgment method, and reaches 1.25ns, the accuracy and the precision of the ultrasonic flow-meter are remarkably improved. The detecting system provided by the invention has the characteristics of small size, low power consumption, stable and reliable measurement and the like; the precision reaches 0.5; the sensitivity attains 0.3mm / s; and the system is suitable for measuring the flow rates and the flow velocities of various liquids in plastic or metal pipes with diameters being 25mm-8m.

Owner:SHENZHEN POLYTECHNIC

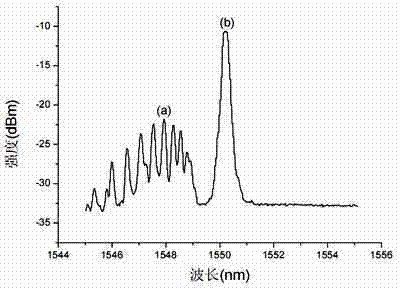

Full optical fiber positioning and monitoring method and system therefor

InactiveCN1635339AAvoid influenceHigh phase sensitivityOptical light guidesConverting sensor output opticallyFiberSonar

This invention relates to a new fiber position monitoring method and its system. The system is characterized by the following: it uses single light fiber as large arrange distribution sensor fiber and gets the disturbing source physical characteristics according to the phase inversion of the interference signals and determines the detail positions of disturbing source according to the frequency spectrum of the interference signals. It uses the sensor fiber end and reflecting lens method to improves the system accuracy.

Owner:FUDAN UNIV

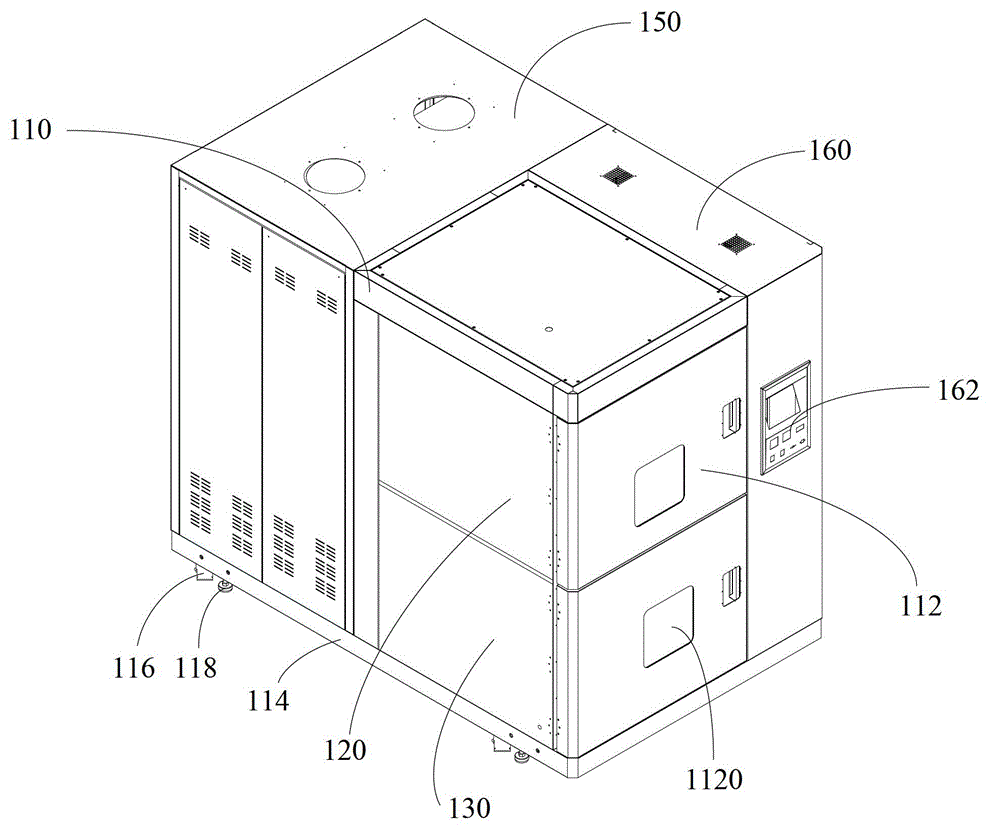

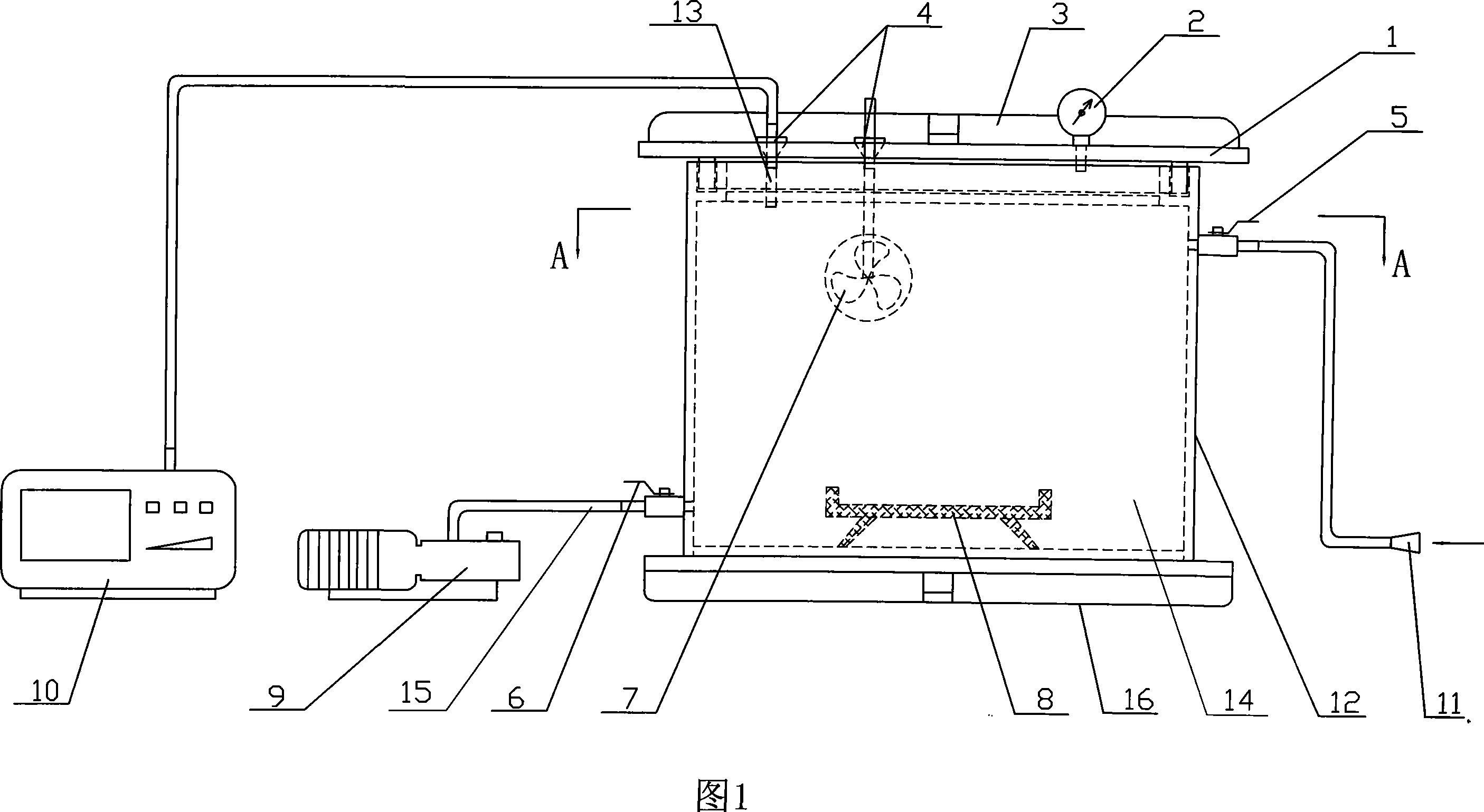

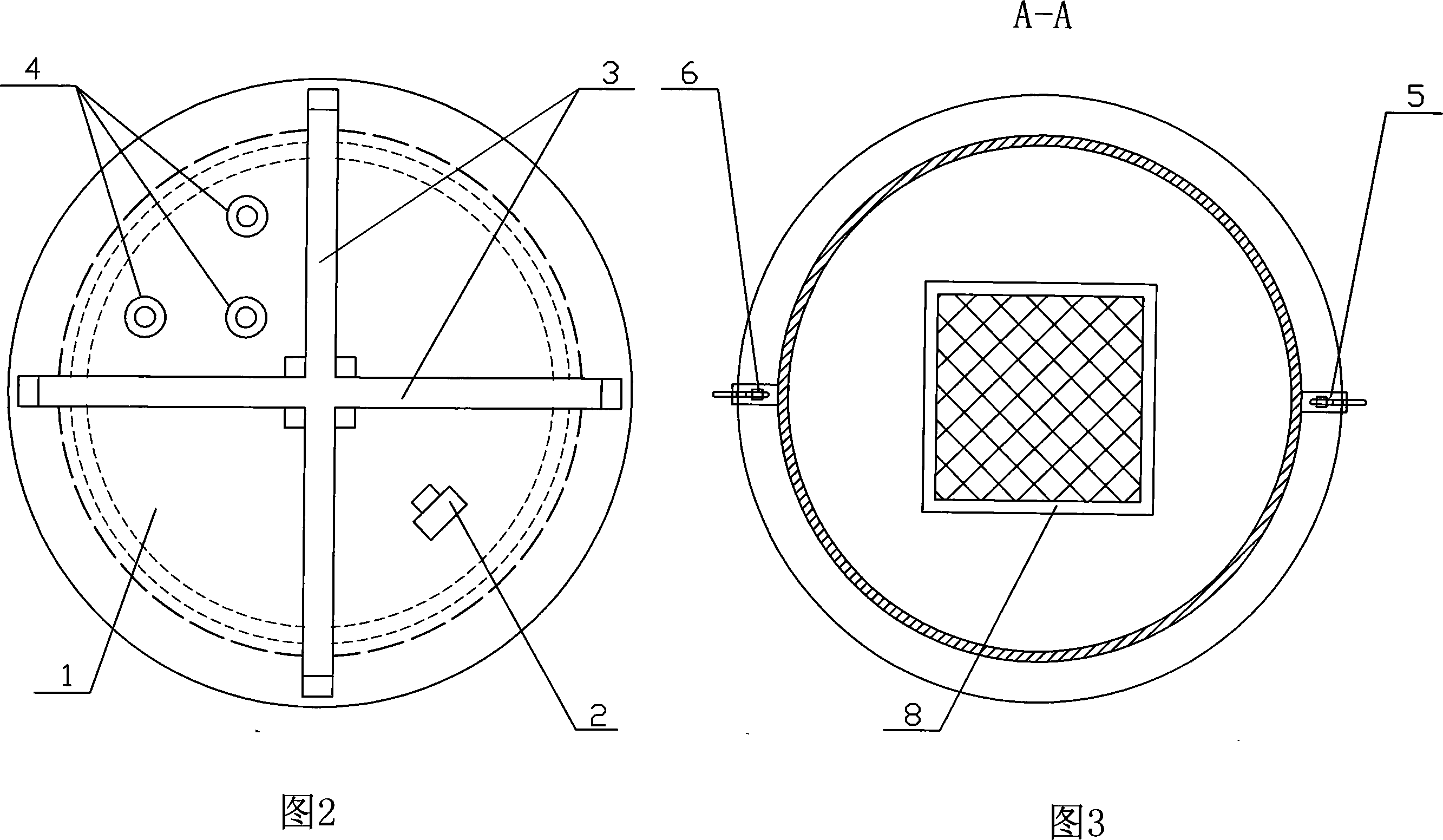

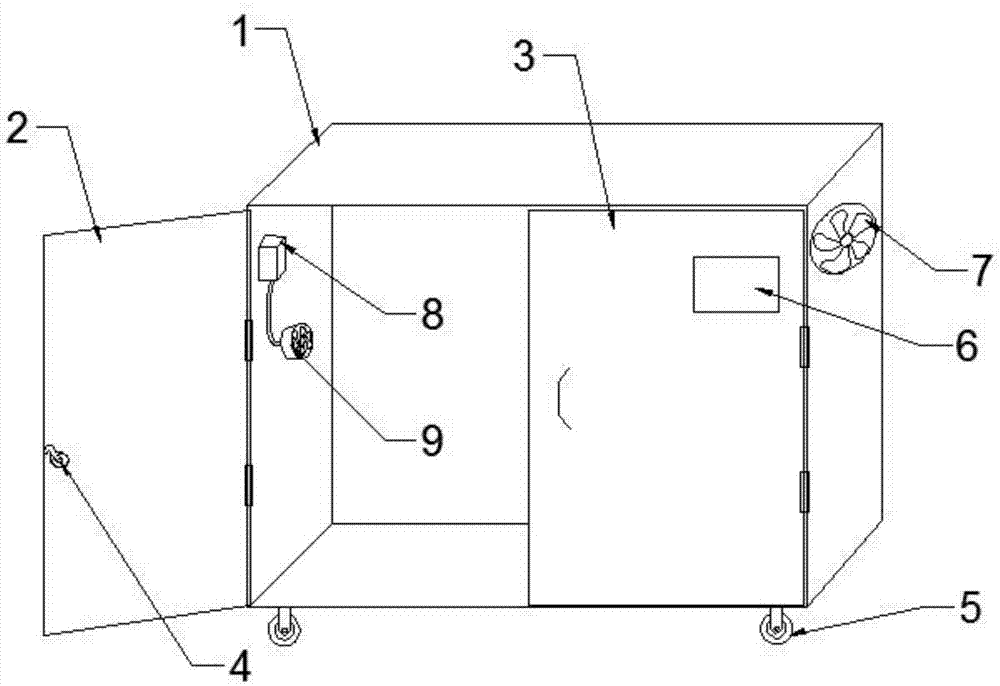

Two-box type impact testing box

The invention discloses a two-box type impact testing box. A hanging basket between a high-temperature box and a low-temperature box is moved to transfer a test sample and a room-temperature box does not need to be arranged, so that the defrosting time can be shortened, the consumption of electric quantity is reduced and the testing cost is saved; inner walls of the high-temperature box and the low-temperature box are respectively provided with a heating device and a refrigerating device; the circulation of air flow is driven by an impeller; the air flow rapidly and circularly flows to realize the effect of rapidly heating the test sample or refrigerating the test sample; an impeller, one heating device, an evaporator, a regenerator and the like are all located on the side wall of the high-temperature box or the low-temperature box; a motor drives the impeller to rotate to drive the air flow to flow in the front and rear direction of the box body; the air flow can rapidly flow and the distribution of the air flow is uniform so as to reduce the formation of frost and realize a long-time defrosting-operation-free circulating continuous test; a driving device for moving the hanging basket is arranged in a refrigerator cabinet rather than in the low-temperature box, so as to avoid influences on the driving device by the low temperature and rapidly move the hanging basket; the safety is high.

Owner:GUANGZHOU CEPREI INSTR & EQUIP

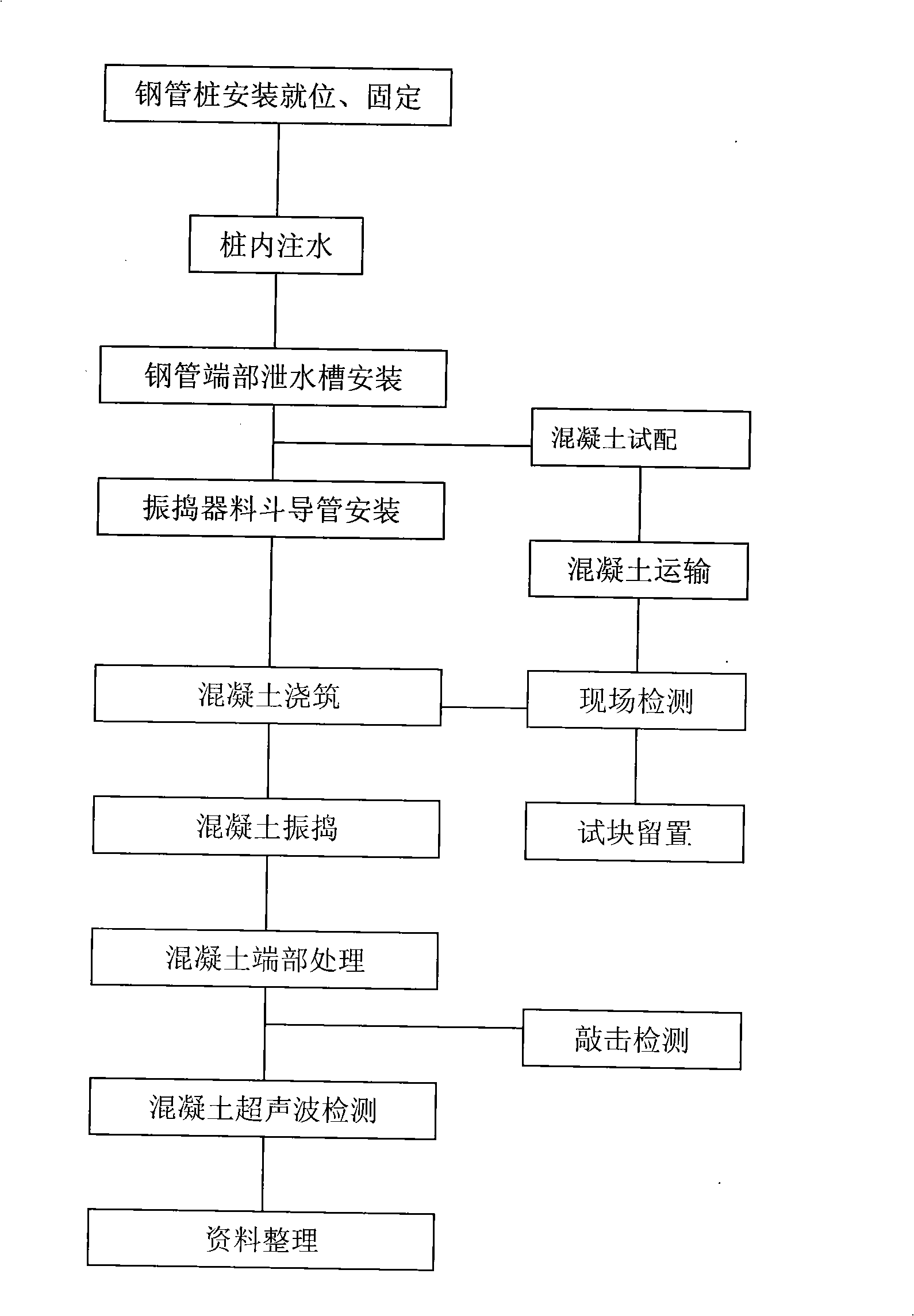

Construction method of steel pipe concrete column

InactiveCN101319550AImprove compactnessReduce air bubblesStrutsCeramic shaping apparatusSteel tubeAir bubble

The invention relates to the building field. The invention relates to a construction method for a concrete filled steel tubular column, comprising the following steps that: a tube is filled with water at first, and then a tremie is put down to the bottom of a pile; concrete is poured into the steel tube by a hopper through the tremie, and a vibrating tamper which is attached to the outerwall of the tube performs concrete vibrating when placing is performed simultaneously; primary concrete placing is performed until the height is 3 to 5 meters on the upper side of a nozzle of the tremie, and the tremie is lifted and guaranteed that the embedding depth of the tremie in concrete is not less than 2 meters; secondary concrete placing is performed, and the vibrating tamper which is attached to the outside of the tube on the bottom layer is started; lifting and placing are repeated, and the concrete is placed to the top of the column; and laitance is removed. The construction method solves the problem of the separation phenomenon caused by overhigh concrete placing height, increases the compactness of the concrete, reduces the number of air bubbles, has small shrinkage clearance between the concrete and the steel tube, can well give play to the function of stress, is convenient in construction, is mechanized, and is simple and convenient in operation. Moreover, the quality can be guaranteed; the equipment is saved by 30 percent; the stability is strong; and 50 percent of raw steel materials and 35 percent of the concrete are saved when the steel tube and the concrete are under same stress, thereby the production cost is effectively reduced.

Owner:DALIAN SANCHUAN CONSTR GROUP

Tester for testing the performance of new material degrading tail gas

InactiveCN101162222AEasy to observeAvoid stratificationChemical methods analysisSolar lightPhotocatalytic reaction

A tester for testing the performance of a new material degrading tail gas relates to a testing unit. The invention solves the problem of limited usage range, light-tightness of a gas reaction chamber, unstable testing result due to the change of temperature and environment, high cost of equipment and complicated structure, all of which are caused by that the prior test equipment does not have light conditions necessary for light-catalyzed reaction. A gas reaction chamber (12) of the invention is made from light transmissible materials, and consists of a cover gasket (1) and a reaction chamber vessel (14) which are in closed connection with each other; a sensor probe (13) is inserted in a jack (4) on the cover gasket (1), and is connected with a tail gas analyzer (10); a vacuum air pump (9) is connected with the bottom of the reaction chamber vessel (14) through a connecting hose (15). The invention has the advantages of unlimited usage range, direct use of solar light source as the reaction condition by the gas reaction chamber, accurate testing result, low cost of equipment and simple structure.

Owner:HARBIN INST OF TECH

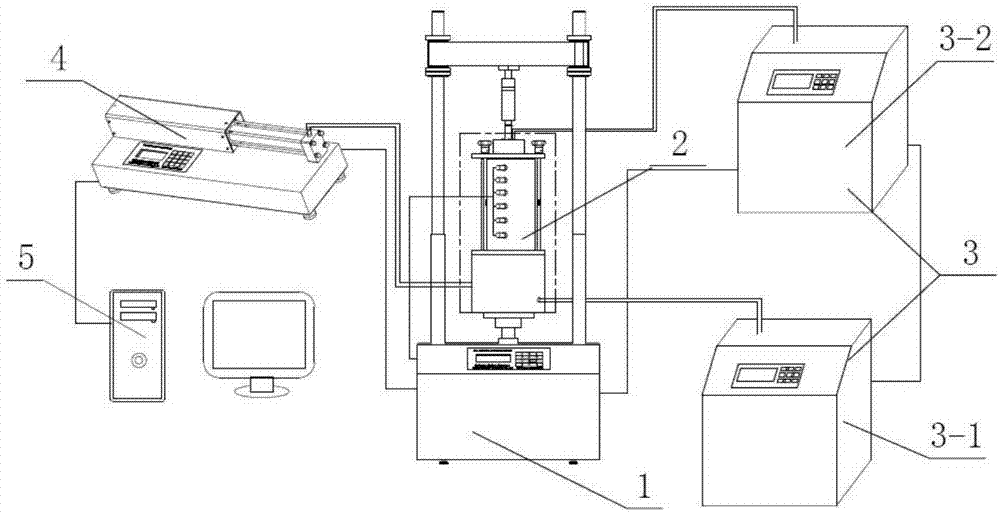

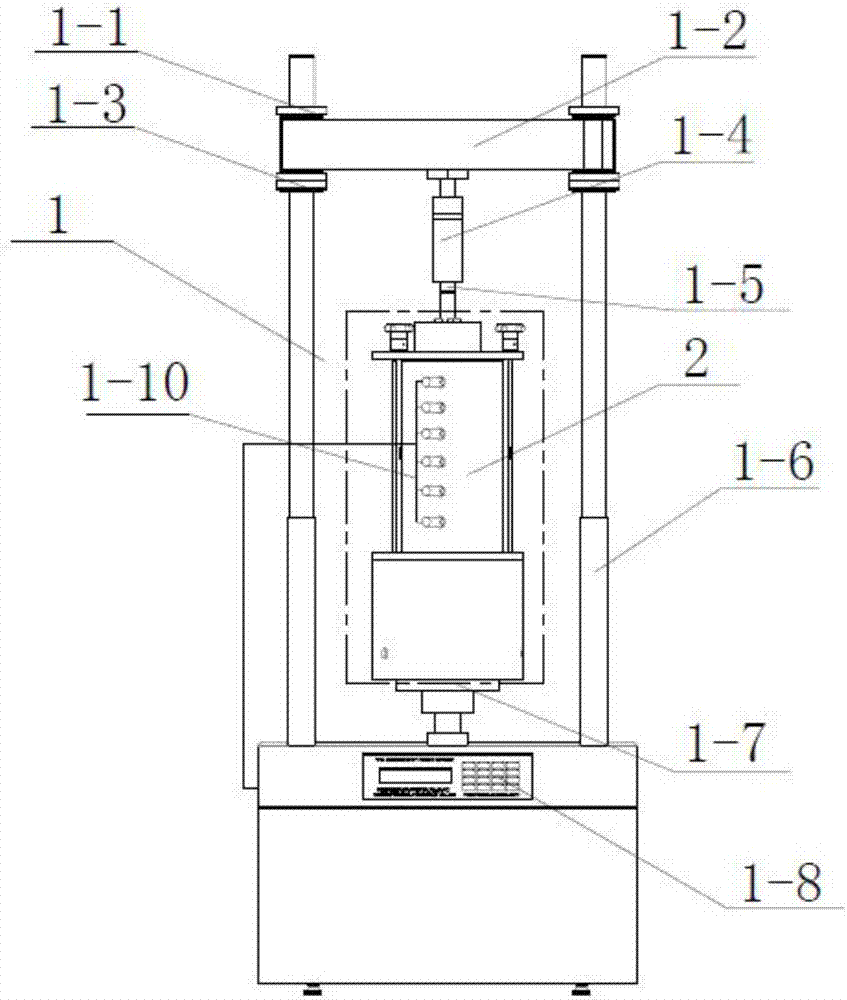

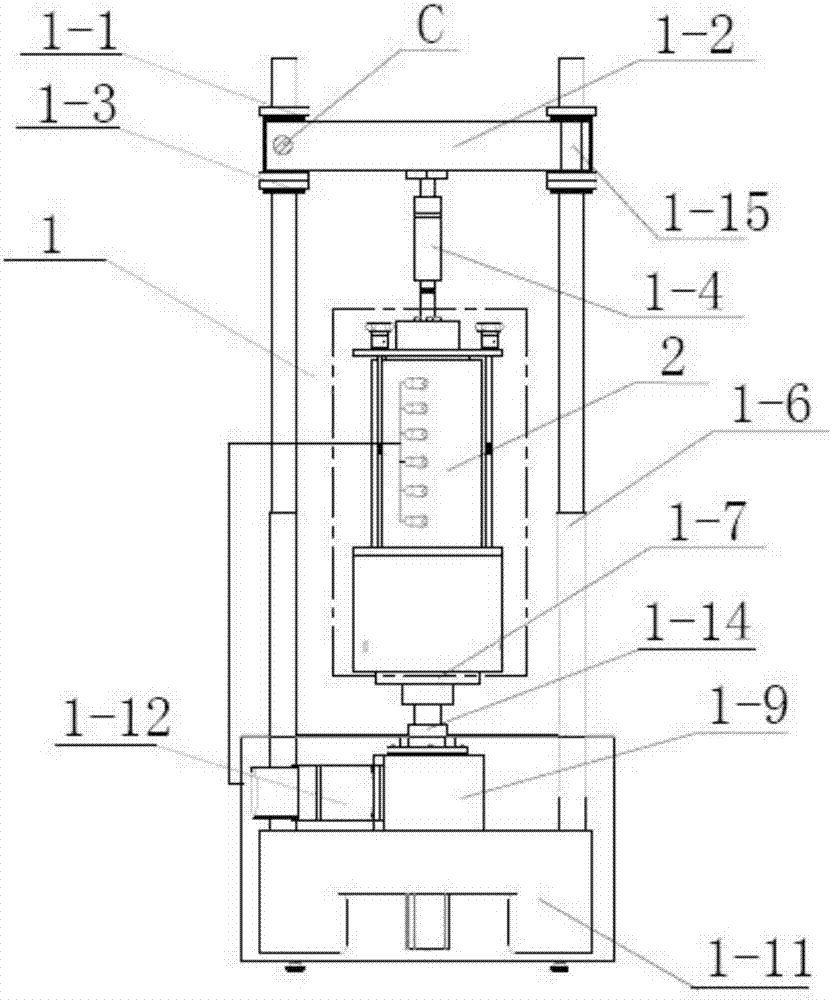

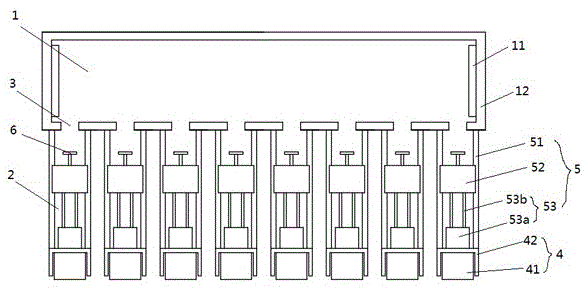

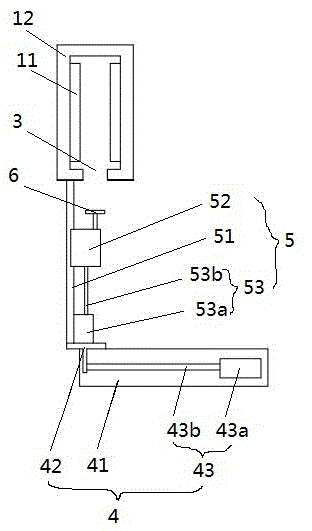

Full-automatic frost heaving meter

PendingCN107238623ARealize fully automatic controlRealize acquisitionMaterial thermal analysisAutomatic controlCycle control

The invention discloses a full-automatic frost heaving meter which comprises a host loading frame (1), a freezing pressure chamber (2) and a high-low temperature cycle control system (3), a water level control system (4) and a computer (5). The freezing pressure chamber (2) is positioned on the host loading frame (1), the high-low temperature cycle control system (3) is connected with the freezing pressure chamber (2), the water level control system (4) is connected to the top of the freezing pressure chamber (2), and the computer (5) is connected with the water level control system (4), the host loading frame (1) and the high-low temperature cycle control system (3) and can be used for test control and acquisition. The full-automatic frost heaving meter can realize automatic control and acquisition of the test process, the requirement of high precision of test control in test can be effectively met by servo closed loop control, and the full-automatic frost heaving meter is high in stability and long in service life.

Owner:南京泰克奥科技有限公司

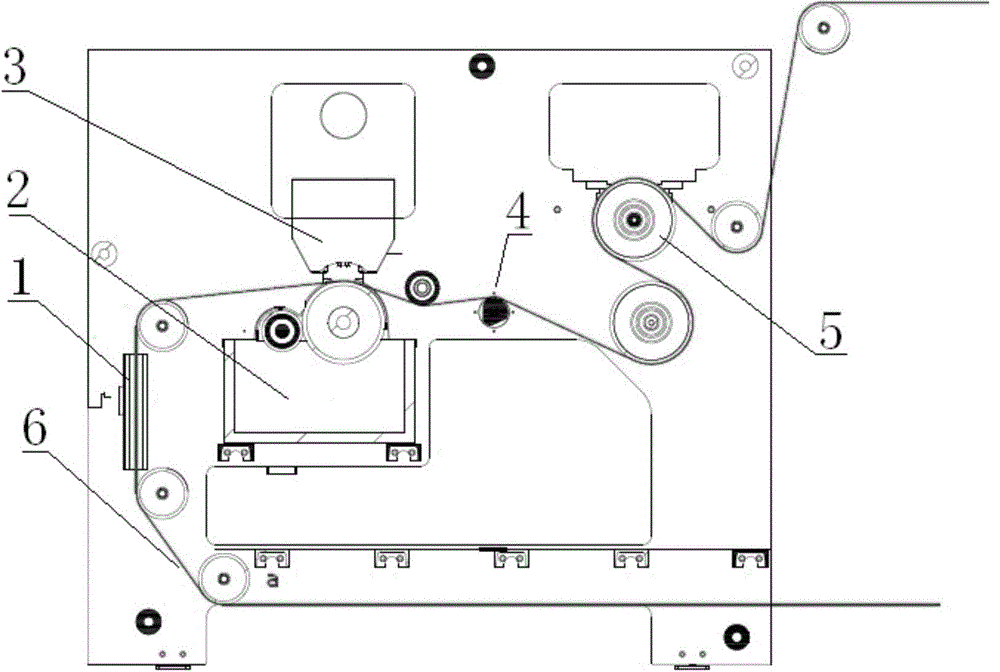

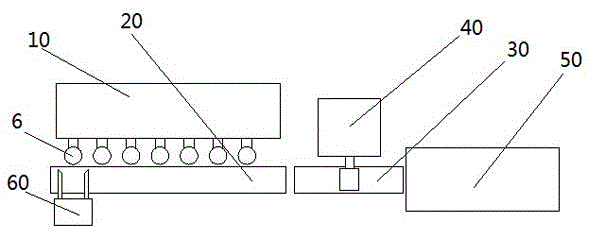

High-speed wax coating apparatus

The present invention relates to a high-speed wax coating apparatus, which comprises a base paper pre-heating assembly for carrying out a pre-heating treatment on base paper before wax coating, a wax melting chamber assembly arranged on the rear portion of the base paper pre-heating assembly and holding a wax liquid for wax coating of the pre-heated base paper conducted to the chamber, a wax feeding assembly having a disk type structure, a wax rubbing roller arranged on the rear portion of the wax melting chamber assembly and used for avoiding wax liquid temperature reduction when contacting the paper surface wax liquid, and a cooling roller arranged on the rear portion of the wax rubbing roller, wherein the lower half portion of the wax feeding assembly is soaked into the wax melting chamber assembly and coats the wax liquid onto the base paper in a rotating manner, and the wax liquid coated on the base paper is cooled in a rapid cooling manner through the cooling roller. Compared with the apparatus in the prior art, the apparatus of the present invention can ensure the stability and the uniformity of the wide-width high-speed wax coating.

Owner:SHANGHAI ZIDAN FOOD PACKAGING & PRINTING CO LTD

Tire tread mixture, tire tread made from tire tread mixture and tire

InactiveCN105218901AAvoid temperature effectsImprove handlingSpecial tyresRolling resistance optimizationRolling resistanceRoad surface

The invention discloses a tire tread mixture, a tire tread made from the tire tread mixture and a tire. The tire tread mixture is prepared from the following raw materials in parts by mass: 30 to 45 parts of natural rubber, 30 to 45 parts of emulsion polymerized butadiene styrene rubber, 10 to 30 parts of cis-butadiene rubber, 45 to 75 parts of carbon black, 15 to 30 parts of white carbon black, 1.2 to 3.6 parts of silane coupling agent, 3 to 5 parts of zinc oxide, 1 to 2 parts of stearic acid, 2 to 4 parts of anti-aging agent, 1 to 2 parts of protective wax, 1 to 2 parts of sulphur, 10 to 20 parts of aromatic hydrocarbon oil, 1 to 2 parts of accelerant, 1 to 3 parts of tackifier, 1 to 3 parts of dispersing agent and 2 to 10 parts of non-slip material. According to the product provided by the invention, the trafficability characteristic and safety on a wet road surface and a smooth ice surface are improved, a proper amount of white carbon black is used and the friction between the product and the ground is larger, so that the controllability and the safety of a vehicle on the wet road surface and the smooth ice surface are greatly improved, and meanwhile, the tire rolling resistance and heat generation in a common environment cannot be affected.

Owner:SICHUAN YUANXING RUBBER

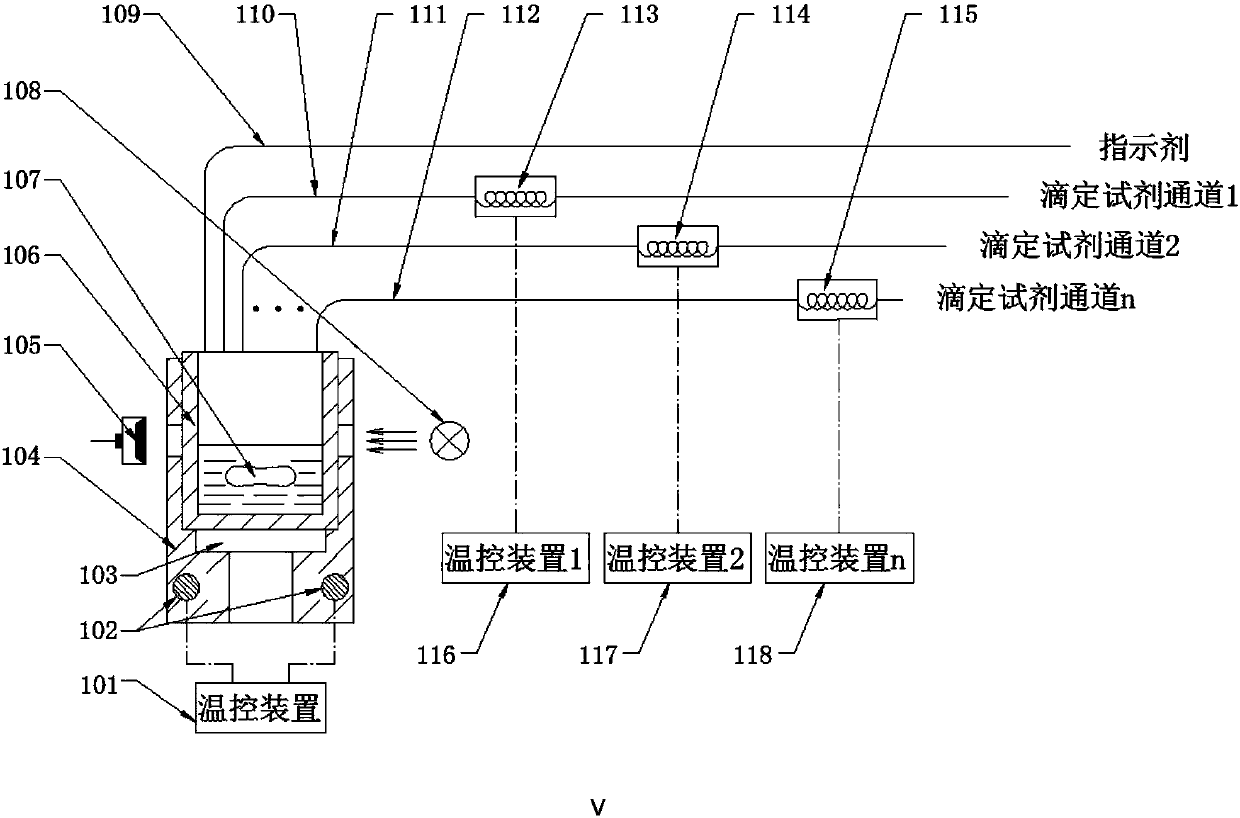

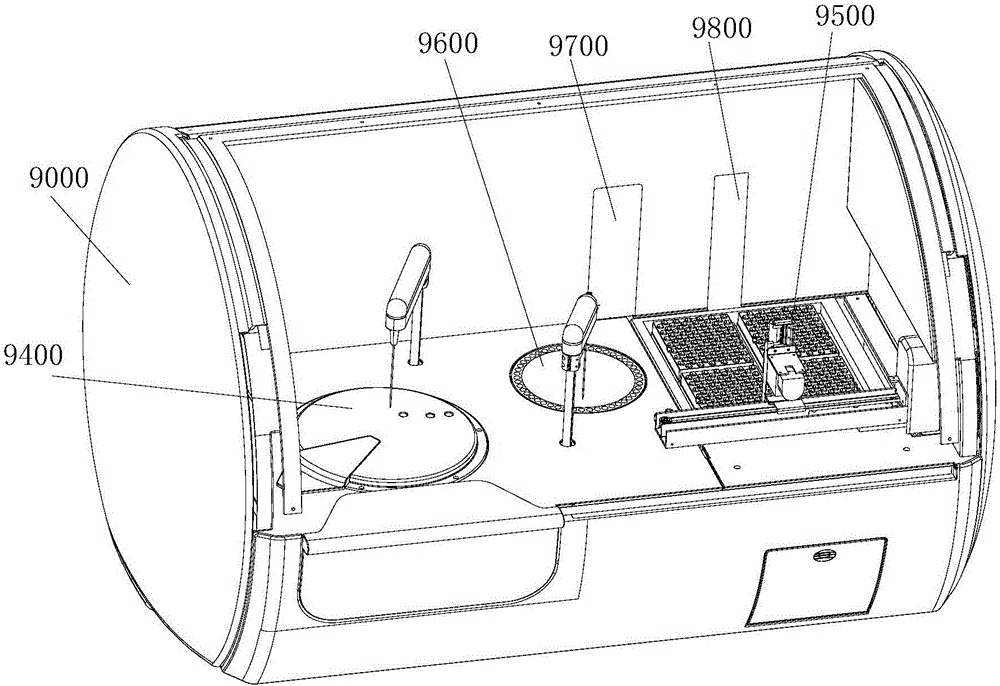

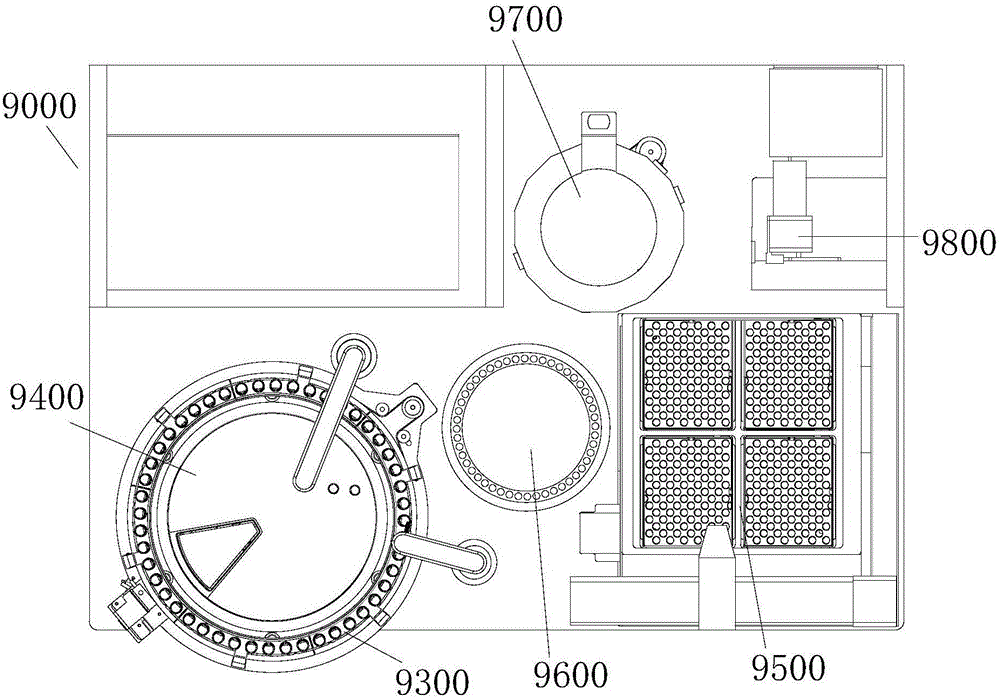

Titration apparatus and titration method applied to analysis meter

PendingCN107764933AFast titrationAccurate titrationChemical analysis using titrationMaterial analysis by observing effect on chemical indicatorTitrationAnalytical chemistry

The invention provides a titration method and a titration apparatus applied to an analysis meter. The titration method is characterized in that the titration apparatus automatically selects and adjusts the concentration of a titration solution and / or the titration speed according to the real-time concentration of a to-be-measured solution until the titration end point is reached, and the to-be-measured index is calculated, wherein the titration apparatus comprises two or more mutually independent titration agent channels, and the agents at different concentrations are conveyed through different channels. According to the titration method and the titration apparatus provided by the invention, the titration scheme is adjusted according to the to-be-measured solutions at different concentrations, so that the effect of rapidly accurately titrating is achieved.

Owner:上海北裕分析仪器股份有限公司

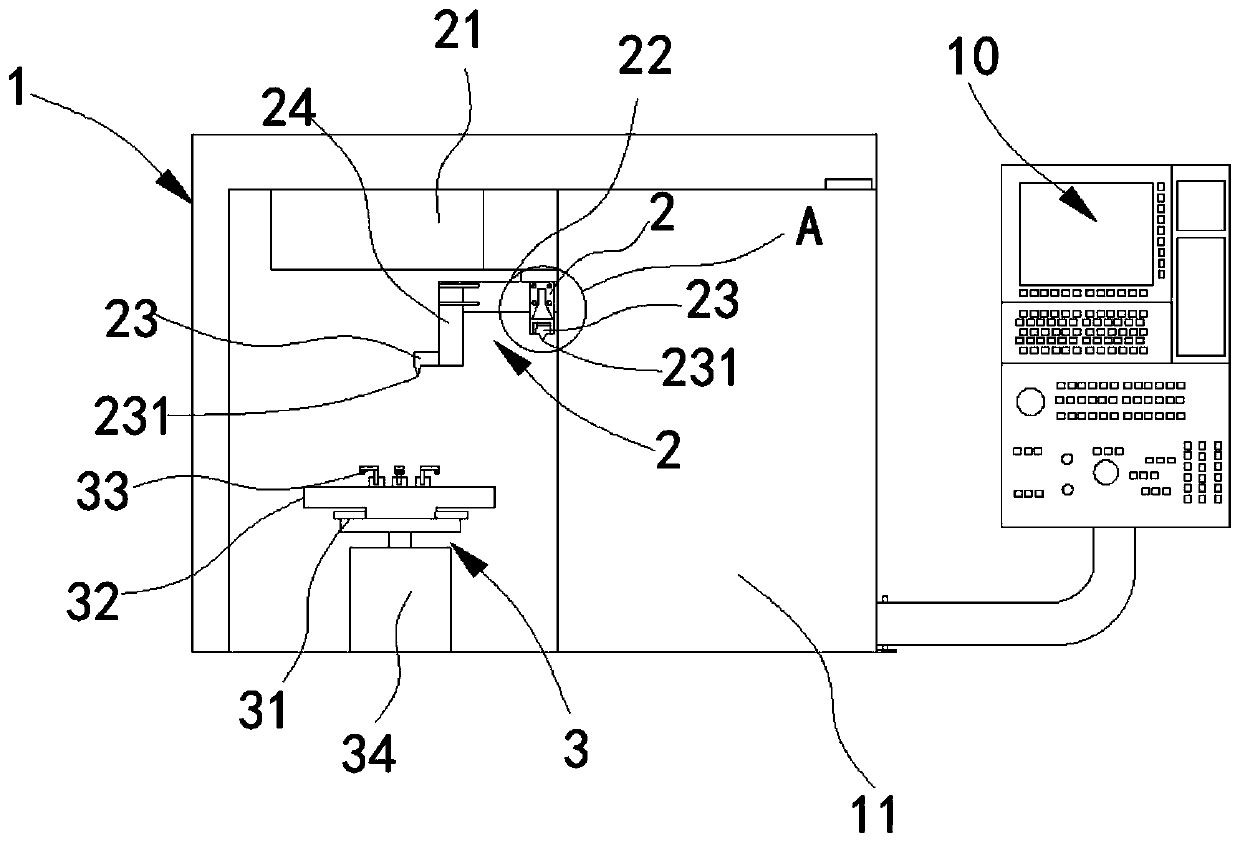

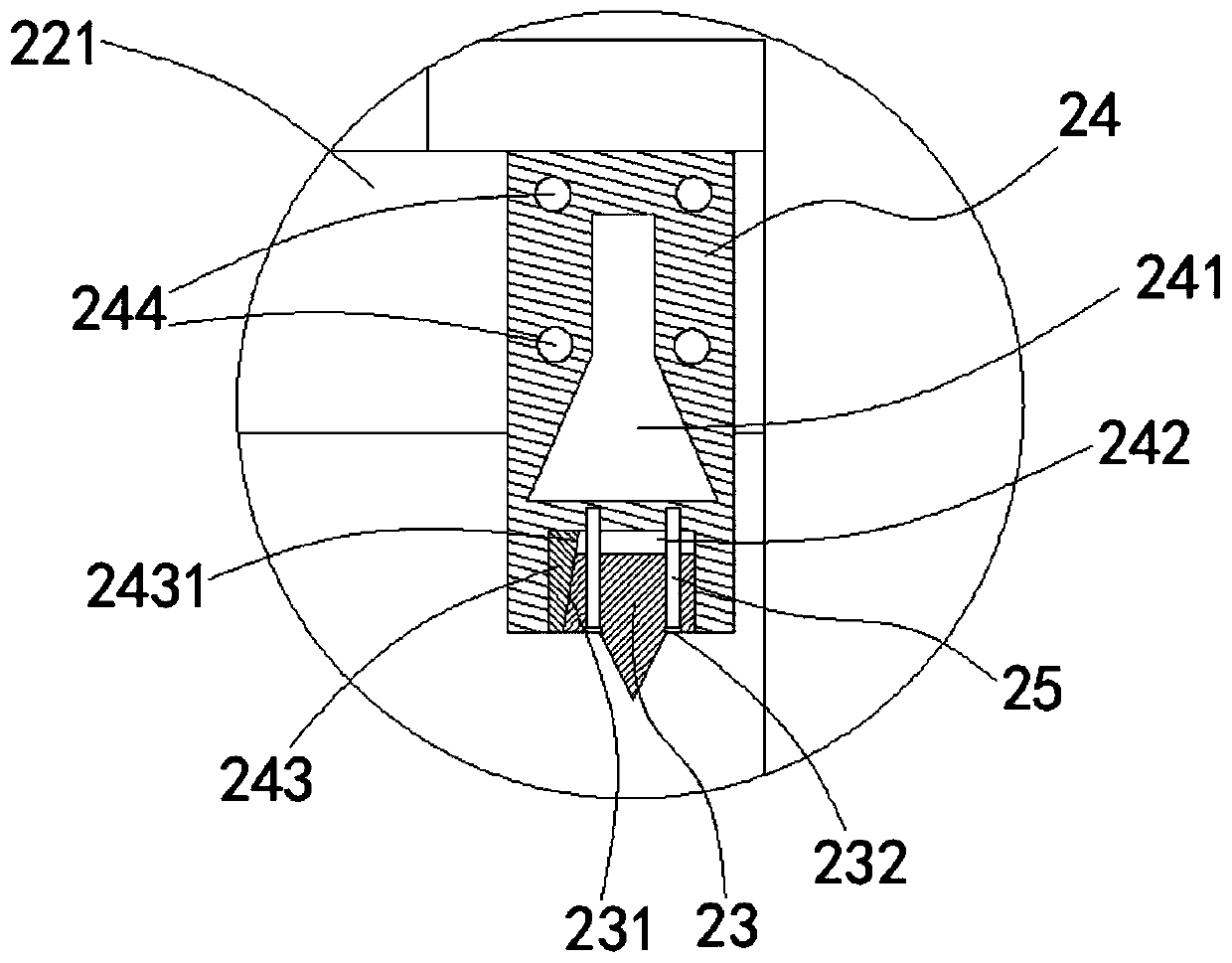

Automatic plasma welding processing equipment

ActiveCN104439666BControllable heating timeReduce lossWelding/cutting auxillary devicesAuxillary welding devicesHeat lossesHeating furnace

Owner:CHANGSHU WEIHENG MOLD MFG +1

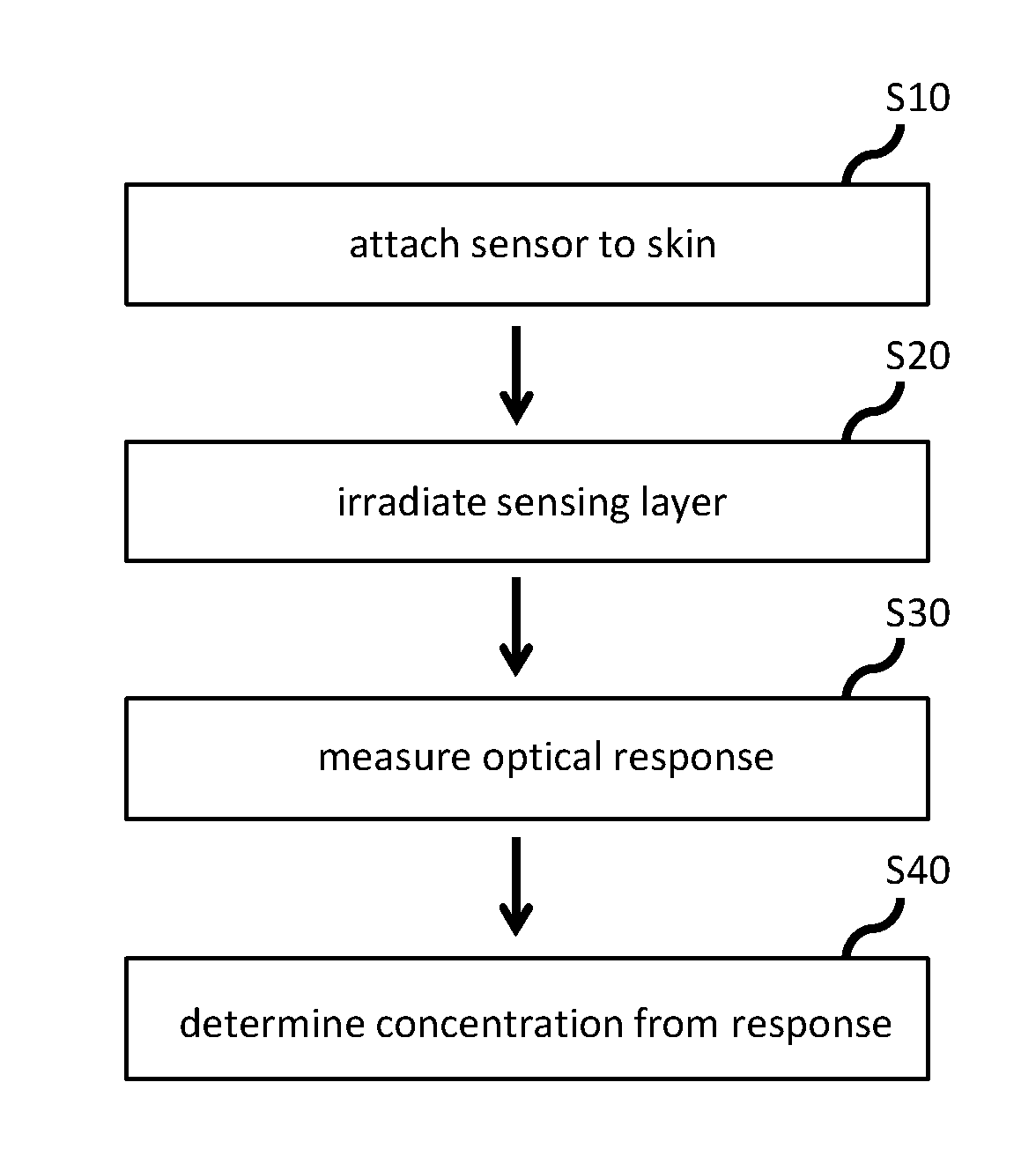

Sensor for determining gas concentration

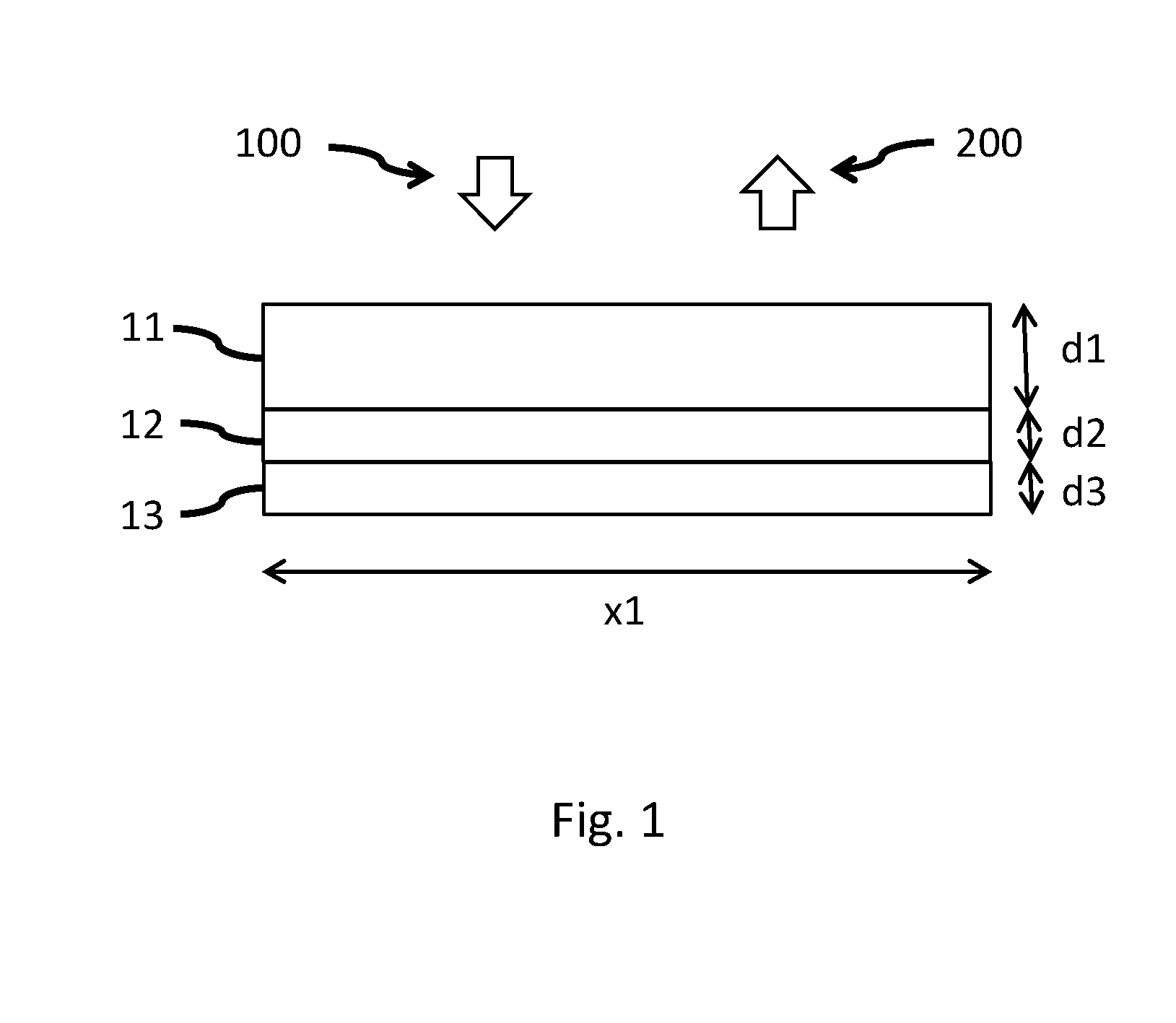

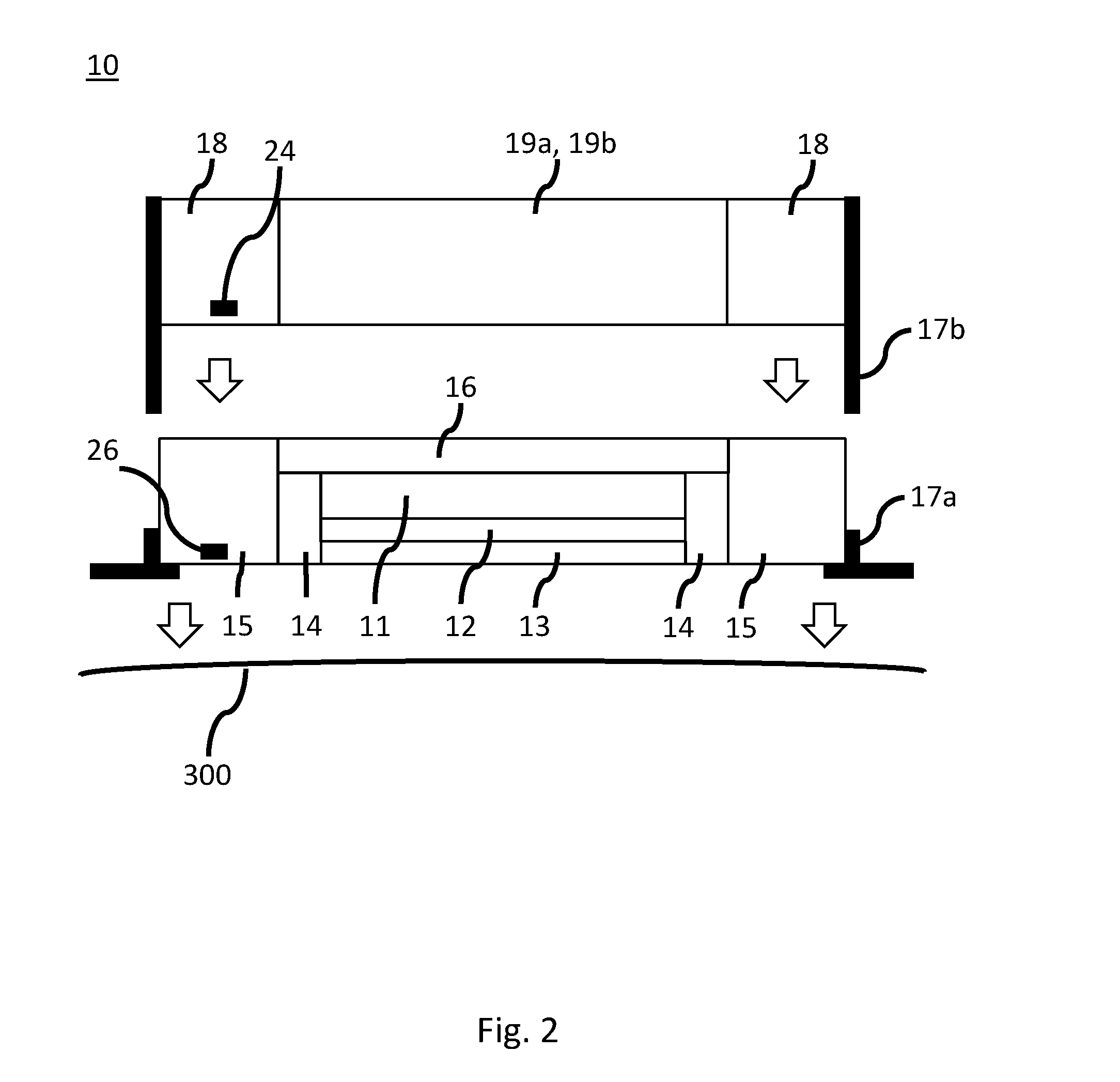

ActiveUS20160007894A1Good heat distributionReduce thermal gradientTransmissivity measurementsDiagnostic recording/measuringThermal insulationEngineering

The present invention provides an optical sensor unit (10) for measuring gas concentration, comprising: sensor means (12, 13) and first thermal insulation means (14, 16) at least partially surrounding said sensor means (12, 13). The sensor means (12,13) includes at least one sensing layer (12) adapted to be irradiated with a predetermined radiation (100), and at least one gas-permeable layer (13) adjacent to one side of the at least one sensing layer (12) and adapted to pass gas, which concentration is to measured, through the gas-permeable layer (13) towards the at least one sensing layer (12). The optical sensor unit (10) is adapted to measure an optical response of the at least one sensing layer (12), which optical response depends on the gas concentration.

Owner:KONINKLJIJKE PHILIPS NV

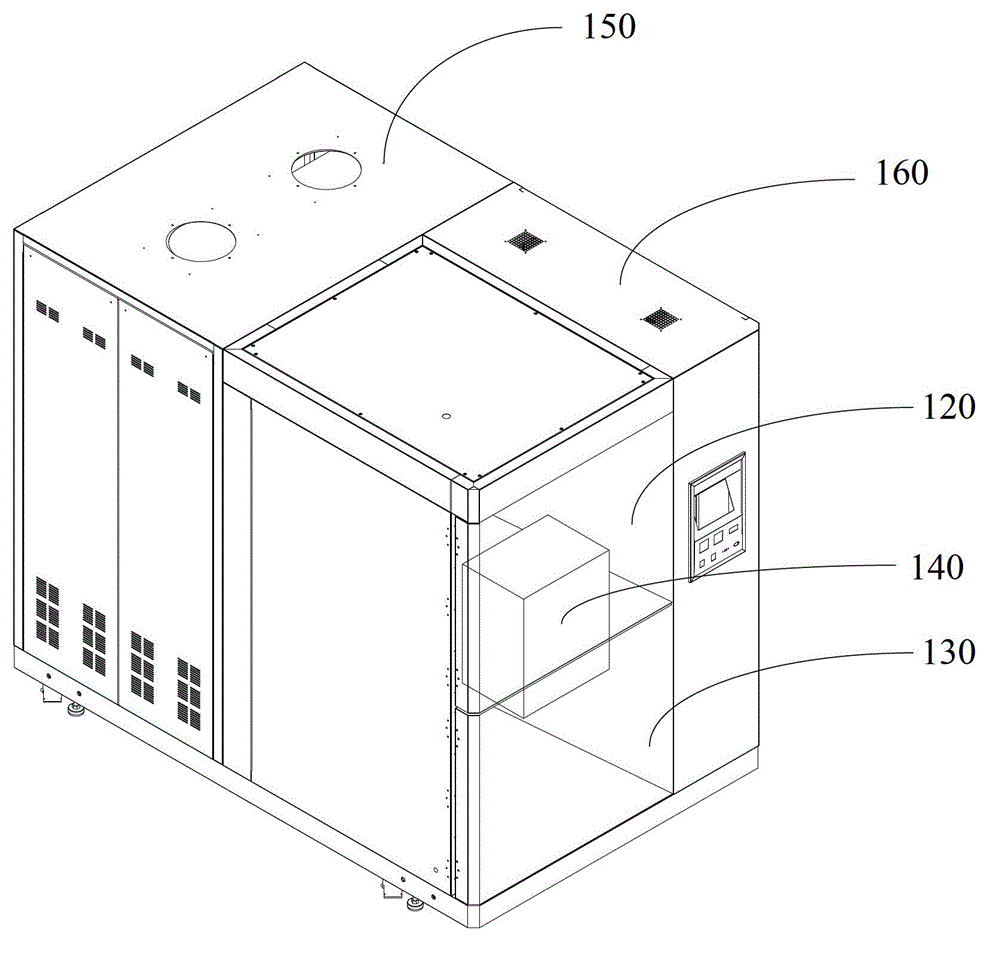

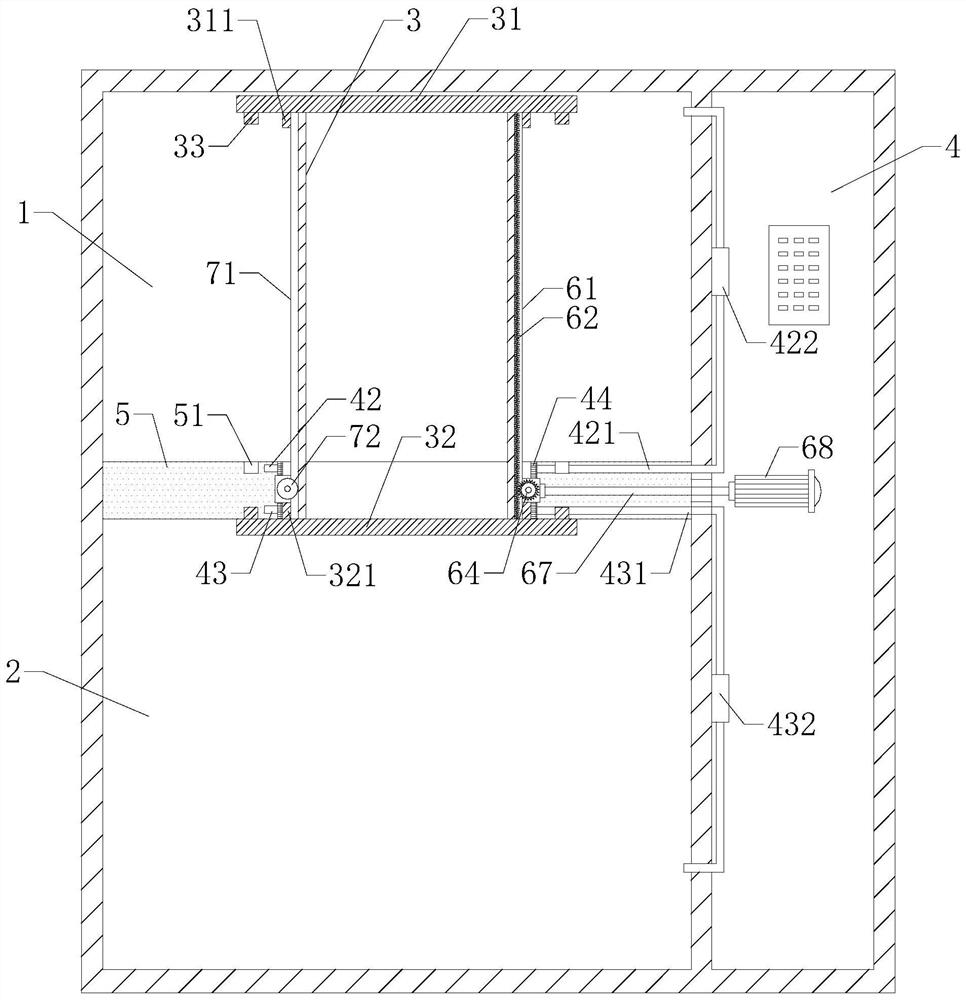

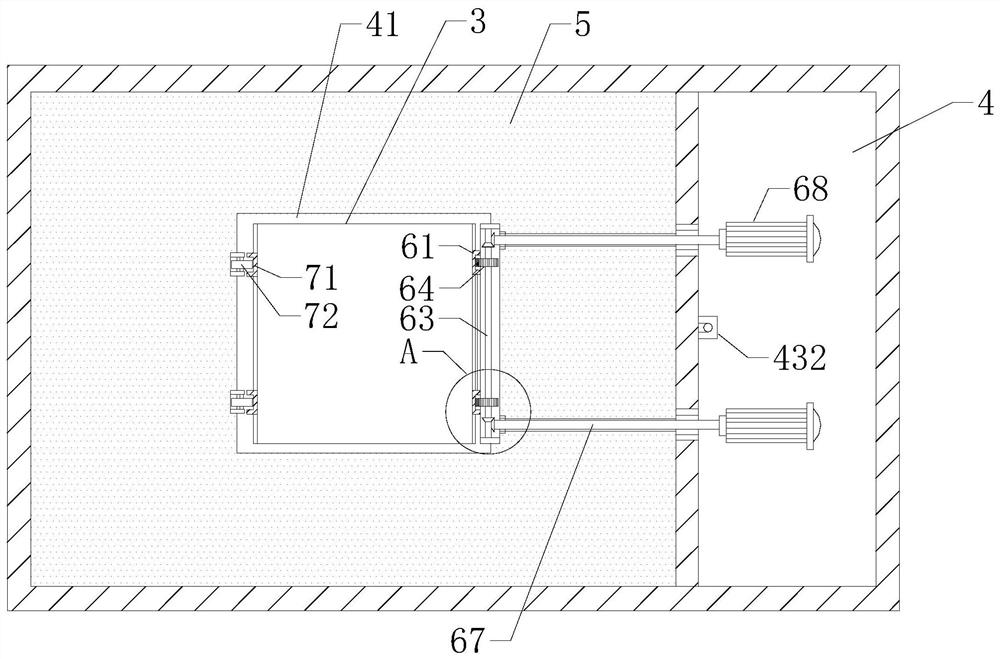

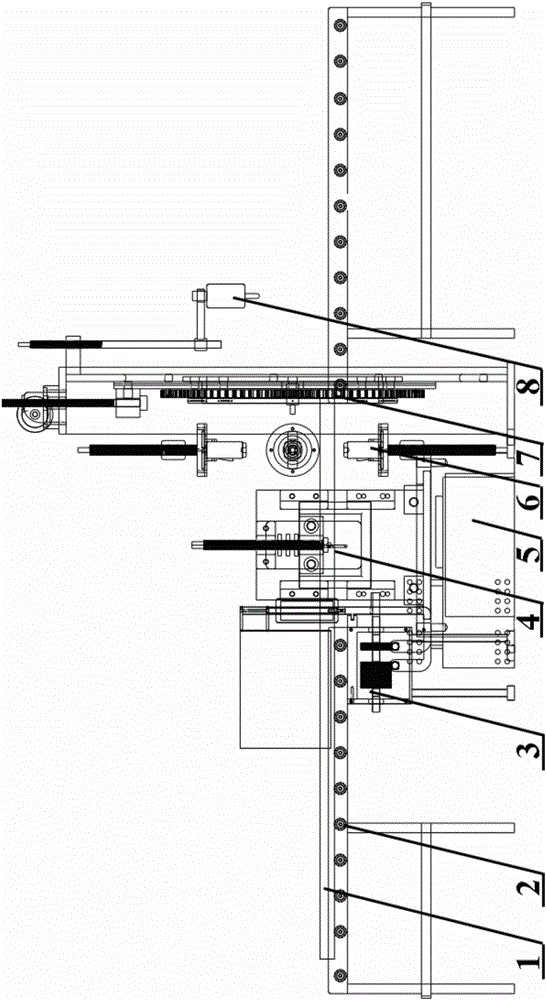

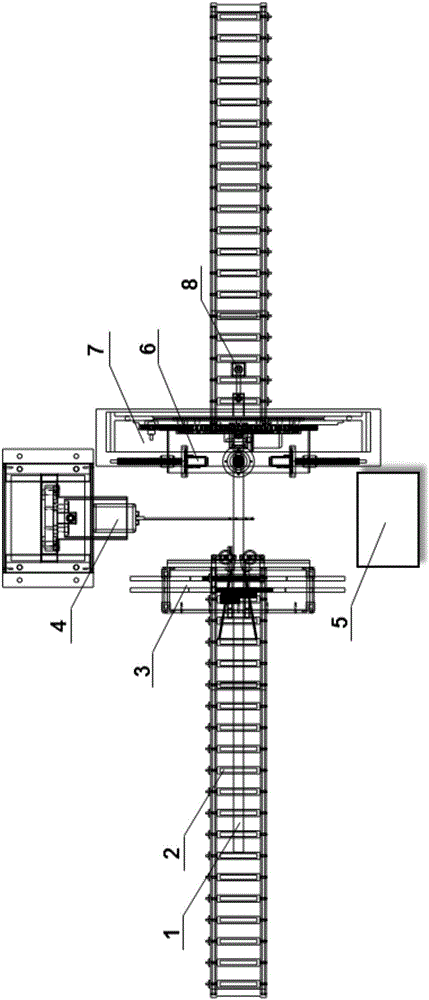

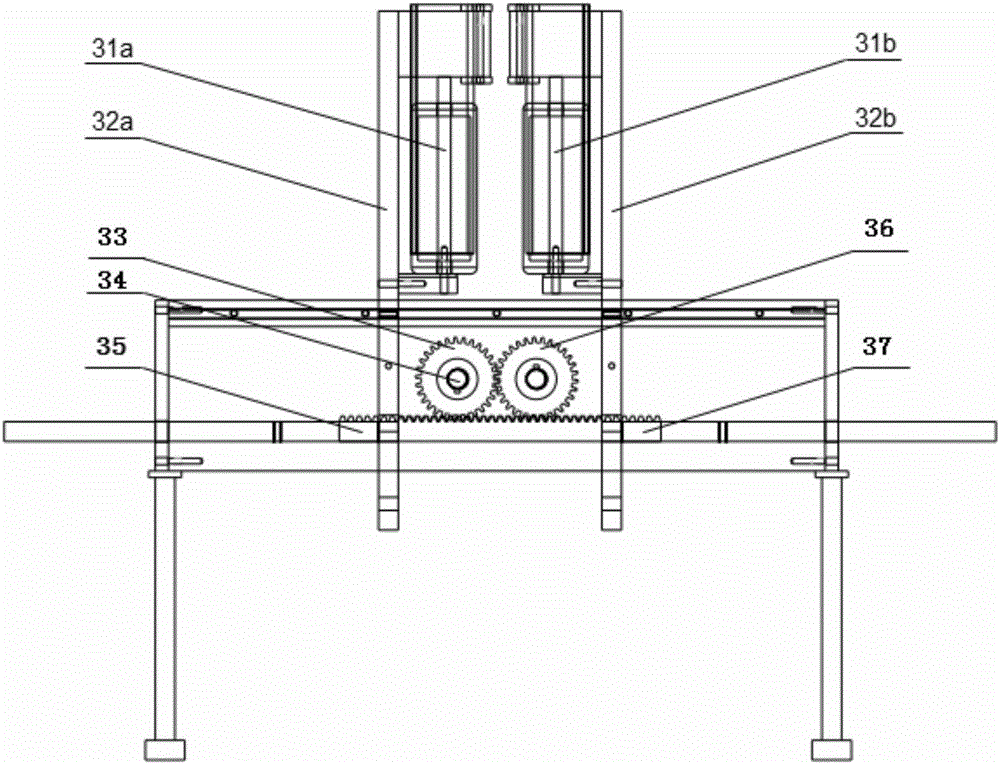

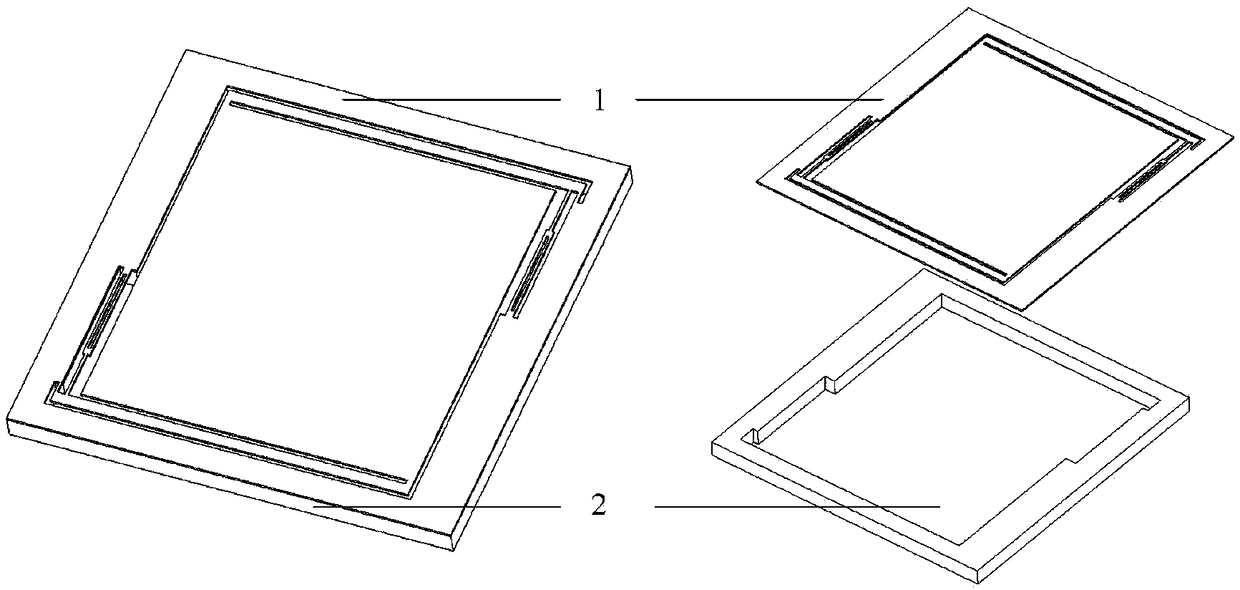

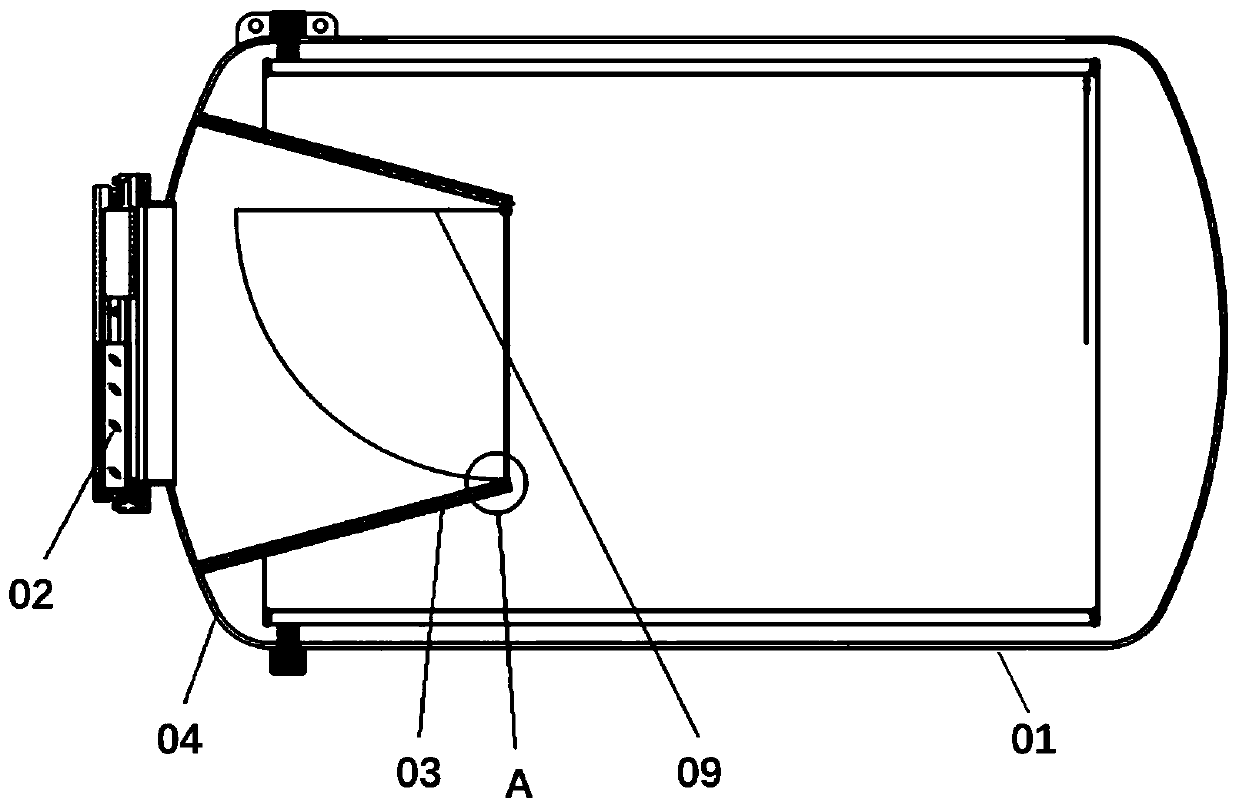

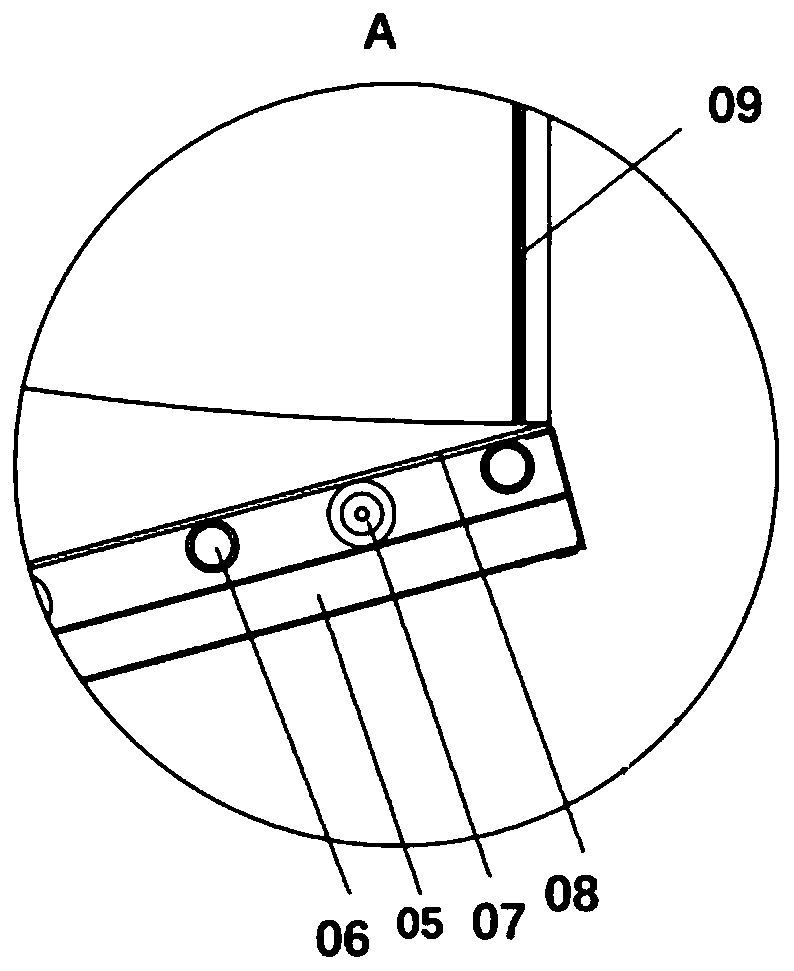

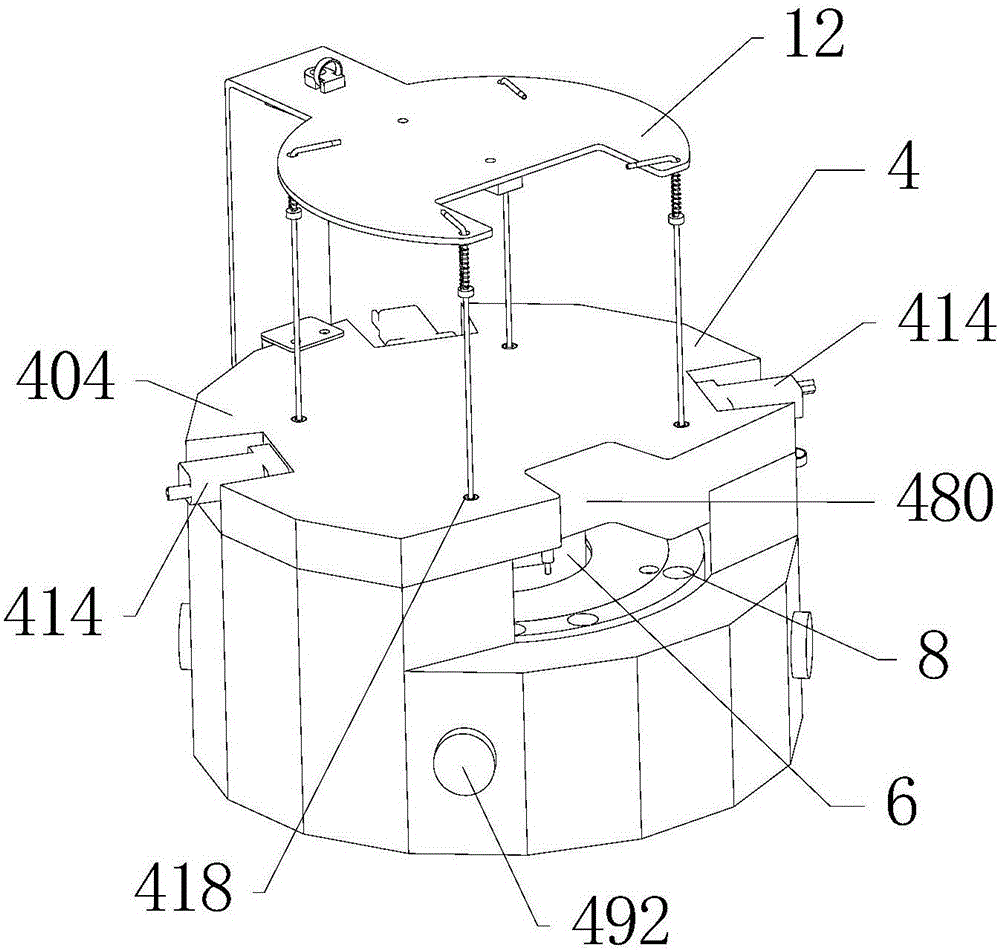

Temperature impact test box

ActiveCN111896414ASave spaceAvoid temperature effectsMaterial thermal analysisStrength propertiesControl systemGear wheel

The invention relates to the field of detection equipment. The invention discloses a temperature impact test box, which comprises a test box body, wherein a high-temperature box body, a low-temperature box body and a test basket are arranged in the test box body; a power box body is connected outside the test box body; a control system, a refrigerating system and a heating system are arranged in the power box body; a lifting device is arranged between the high-temperature box body and the low-temperature box body; an interlayer is arranged between the high-temperature box body and the low-temperature box body for separation; a through hole is formed in the interlayer; and the lifting device is arranged on the inner side wall of the through hole. The lifting device comprises a power guide assembly; the power guide assembly comprises a plurality of guide rails vertically arranged on one side face of the test basket; toothed bars are arranged on the guide rails; a driving shaft is horizontally arranged on the side wall of the through hole; a plurality of gears are fixedly arranged on the driving shaft in a sleeving mode; the gears are meshed with the toothed bars; and the driving shaft is connected with driving equipment. The temperature impact test box provided by the invention has the advantages of stable and rapid rising and falling of the lifting basket, good temperature isolation between the high-temperature box body and the low-temperature box body, and no temperature interpenetration in the lifting process.

Owner:CHENGDU INVATEU TEST EQUIP CO LTD

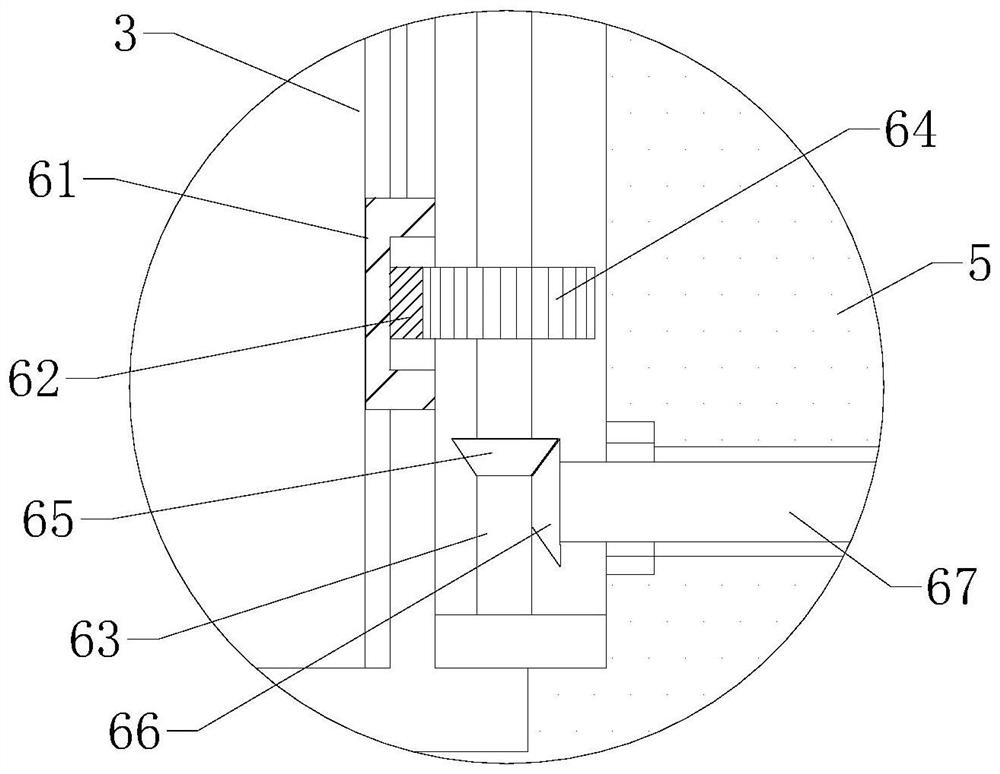

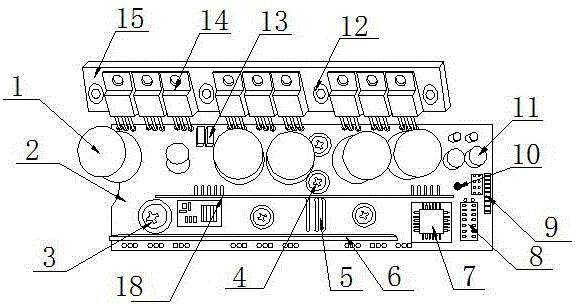

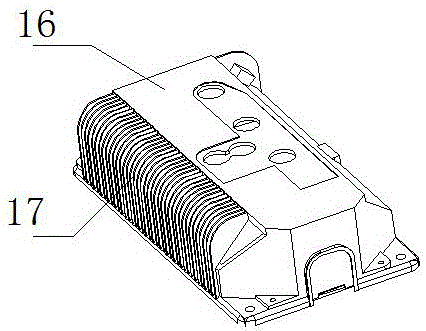

Power controller based on die-casting mould structure

InactiveCN106659038AImprove cooling effectImprove performanceCircuit arrangements on support structuresHermetically-sealed casingsPower controllerBridge type

The invention discloses a power controller based on a die-casting mould structure. The power controller comprises a large-current filtering element, a main PCB, a three-phase motor output terminal, a power input terminal, a current detection element, a bus bar, a master control MCU, a signal input filtering module, a wiring terminal, an indicating lamp, an auxiliary power supply discrete element, an elliptical positioning hole, an upper and lower bridge separation driver, a power switch tube, an aluminum substrate, an aluminum housing, heat dissipation teeth and a bridging type crossover auxiliary PCB. According to the technical scheme of the power controller in the invention, a double-row aluminum substrate and an aluminum shell are connected to improve heat dissipation effect, so that the thermal damage to the switch tube is reduced. Based on the bridging manner of PCBs, the current uniformity of power switch tubes connected in parallel is guaranteed to the greatest extent. Meanwhile, the large-current impact resistance of the entire circuit is improved. The power input terminal and three output terminals (U, V and W) are led out in the casting mode by using a copper column and the aluminum shell of a die-casting mould. Therefore, the problem that water flows into the incoming and outgoing lines and the structure of a common controller in the prior art can be solved.

Owner:刘军

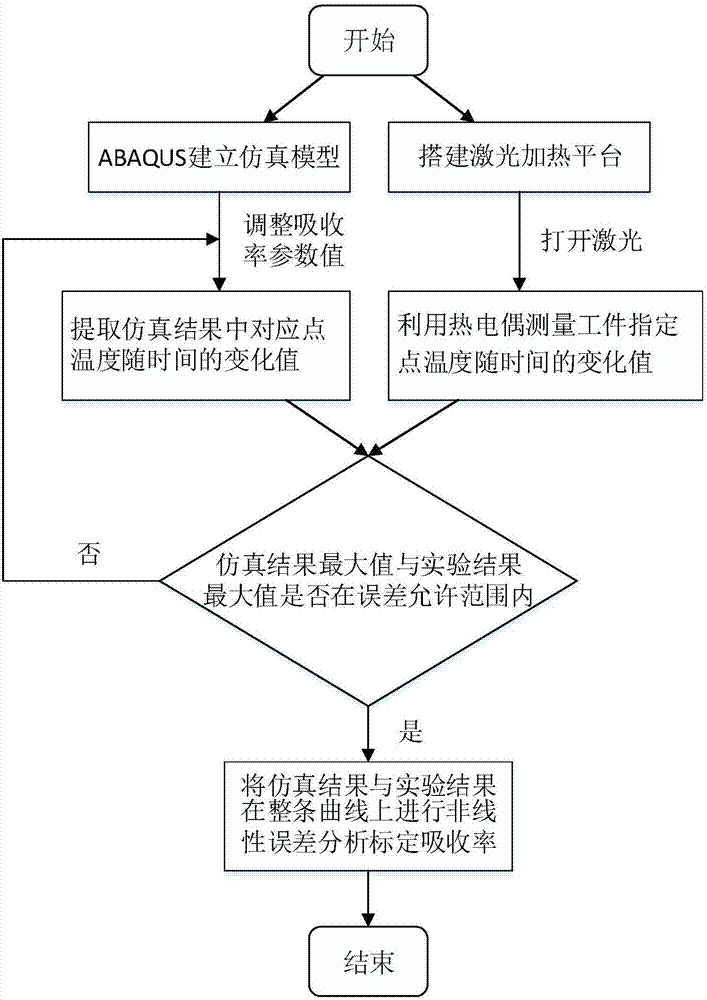

Method for calibration of laser absorptivity of metal material

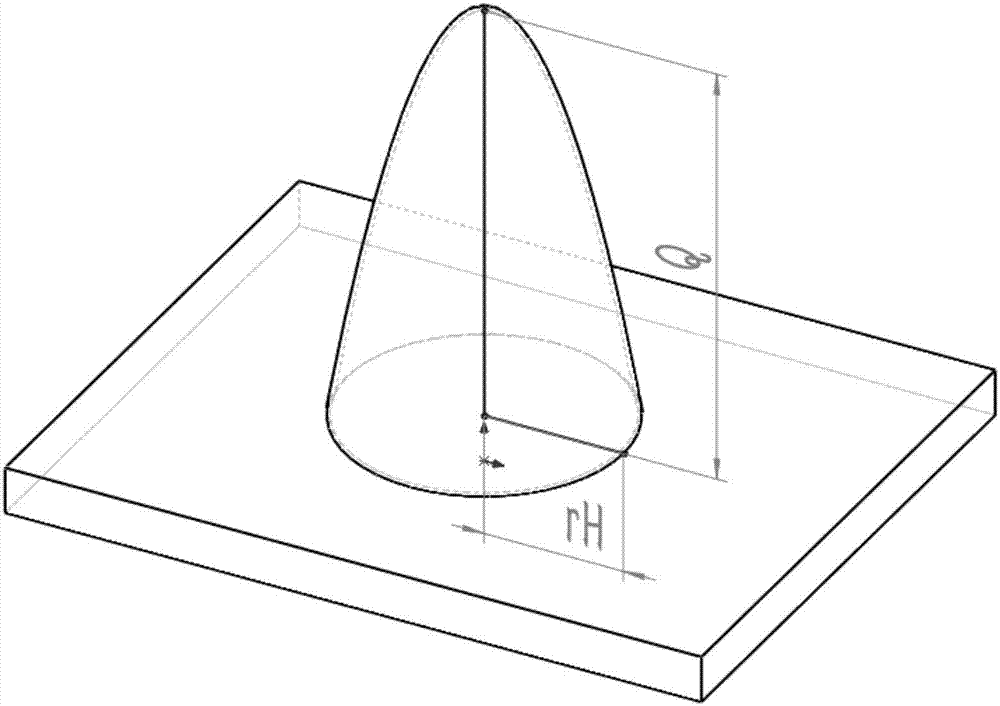

ActiveCN107462597AGuaranteed accuracyLess susceptible to interferenceMaterial heat developmentMetallic materialsCalibration result

The invention belongs to the field of laser preheating auxiliary processing and particularly relates to a method for calibration of laser absorptivity of a metal material. The method comprises a step S1 of utilizing a thermocouple to measure a temperature value of a test point of a workpiece varying with time under laser radiation; a step S2 of establishing a heat source model of the workpiece, adopting the heat source model to perform a simulated test, and obtaining a temperature value of a corresponding point of the test point varying with time on the heat source model; a step S3 of adjusting a parameter of the laser absorptivity input into the heat source model; and a step S4 of causing simulated test results to undergo a non-linear error analysis with an actual measurement result respectively, wherein a laser absorptivity parameter corresponding to an obtained optimal result is the laser absorptivity of the metal material. According to the method, a high-precision calibration result can be obtained, the process is simple, a test device is easy to obtain, small in calculated amount and is not easily disturbed by external factors, and thus the method is particularly suitable for testing the laser absorptivity of the metal material.

Owner:HUAZHONG UNIV OF SCI & TECH

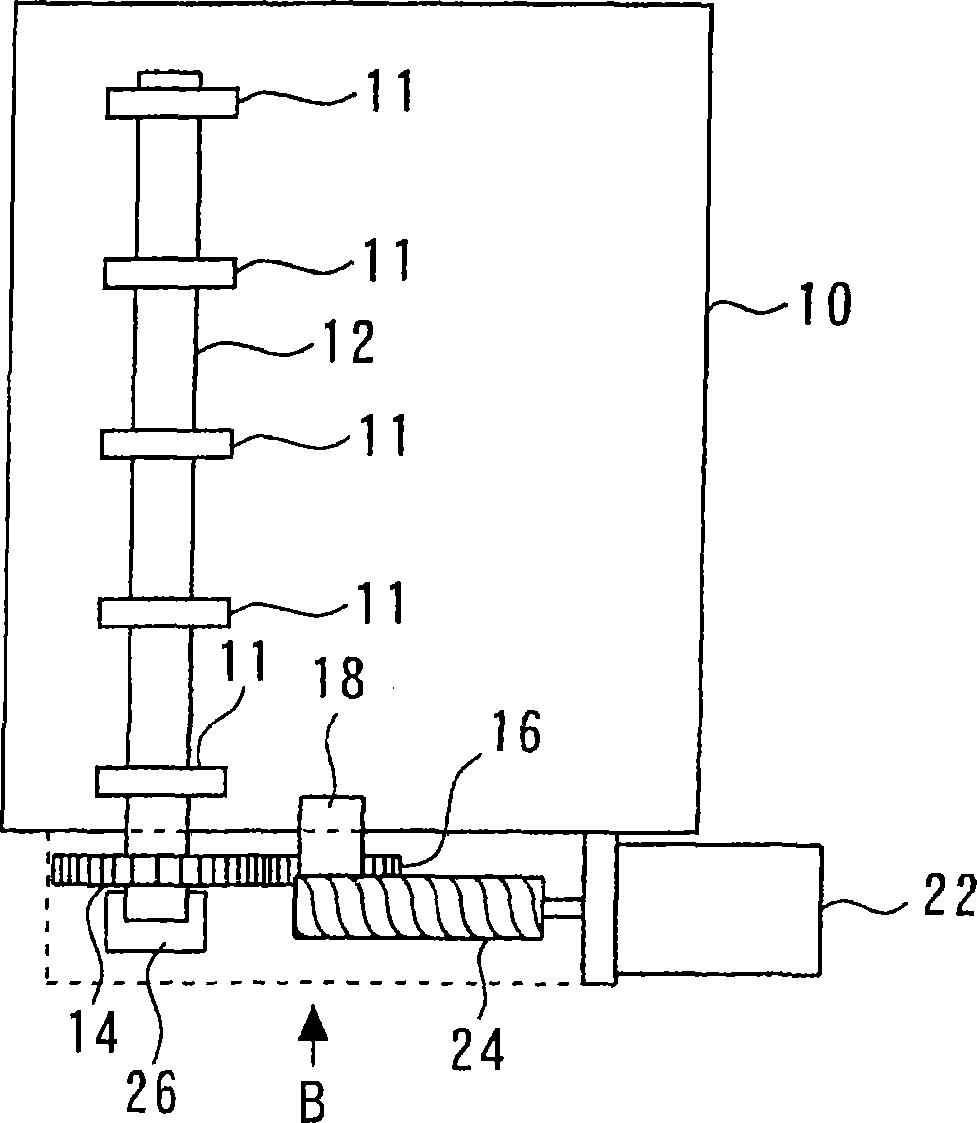

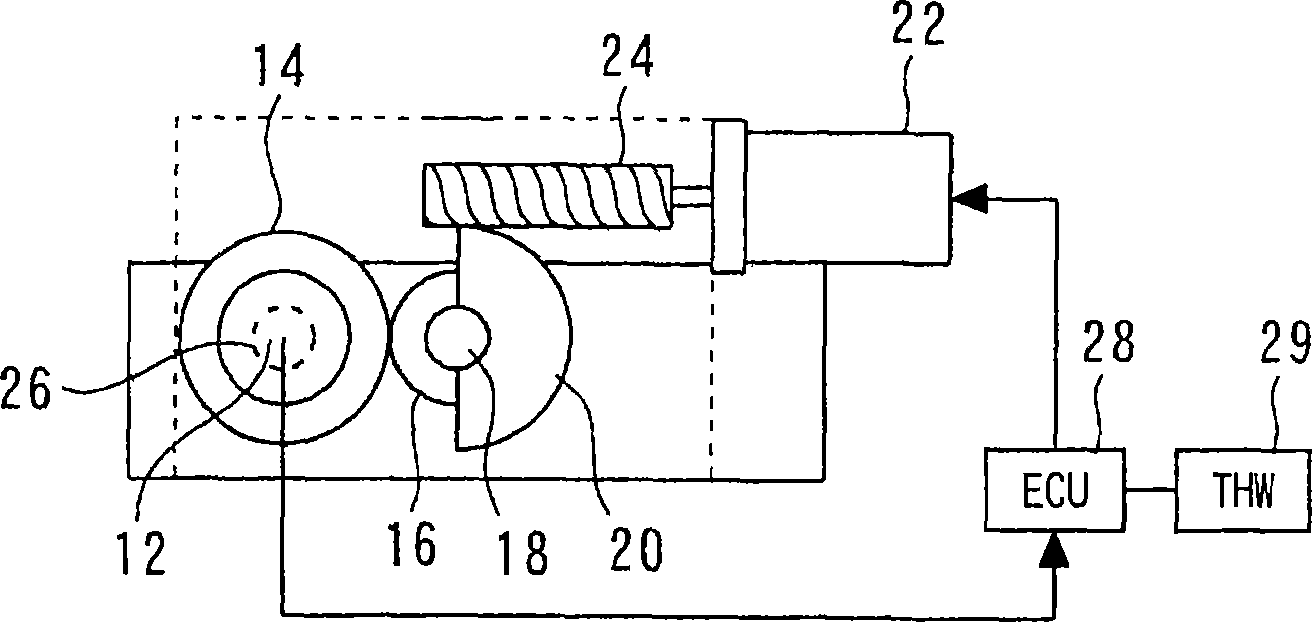

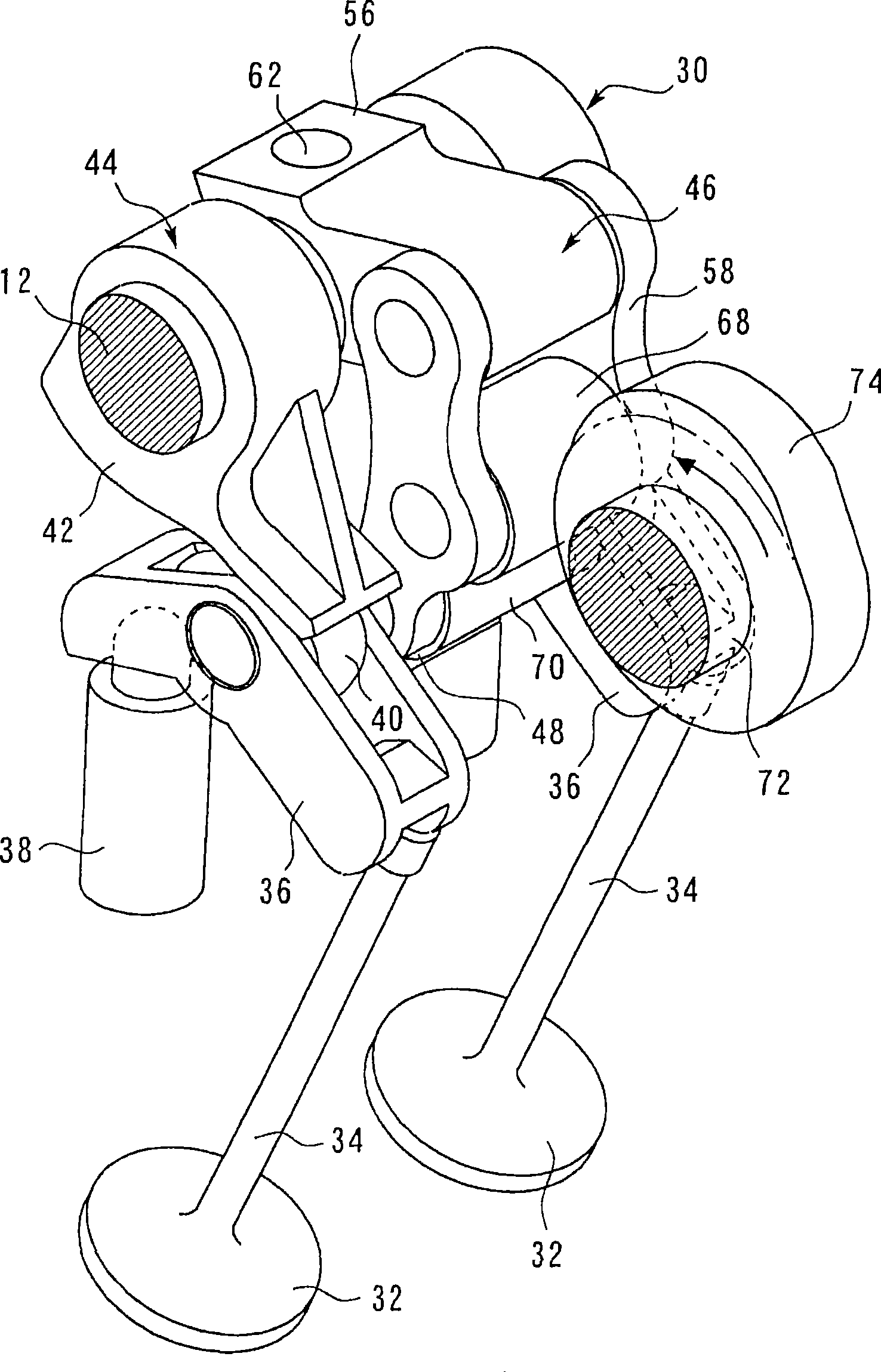

Variable valve system

InactiveCN1894488AEnable feature stabilityProvide stableValve arrangementsInternal combustion piston enginesEngineeringCam

A first arm member and a second arm member are provided. The first arm member is positioned between a cam and a valve body to oscillate in synchronism with the rotation of the cam. The second arm member changes the angle of the first arm member in accordance with the rotation angle of a control shaft. The temperature prevailing in the neighborhood of the control shaft and cam is detected. The rotation angle of the control shaft is corrected so as to avoid the influence of the detected temperature.

Owner:TOYOTA JIDOSHA KK

Field-eddy thermal imaging detection system and method for surface defect of steel product/billet

ActiveCN106770635ARealize continuous online detectionEqual distanceMaterial flaws investigationMaterial magnetic variablesProduction lineTemperature difference

The invention relates to a field-eddy thermal imaging detection system and a method for a surface defect of a steel product / billet. The system can be embedded into a steel product / billet forming production line as an automatic detection and marking module. The method comprises the following steps that a) a to-be-detected object enters an aligning device by a feeding rack; b) the surface temperature of the steel product / billet is transiently heated by high-frequency induction heating equipment in a heating area; c) a thermal infrared imager detection area is entered; d) a thermal infrared imager transmits a signal to a PC (Personal Computer) to obtain temperature difference data of an image and aftertreatment is performed on the image; and e) when the temperature difference of the image is greater than or less than a certain designated value, the PC gives an alarm and transmits a signal to an automatic spray gun for marking to realize automatic marking of a defect position. The method is high in detection speed and high in efficiency, avoids influences caused by nonuniform heating and environmental factors, and can accurately identify and mark the surface defect of the steel product / billet.

Owner:UNIV OF SCI & TECH BEIJING

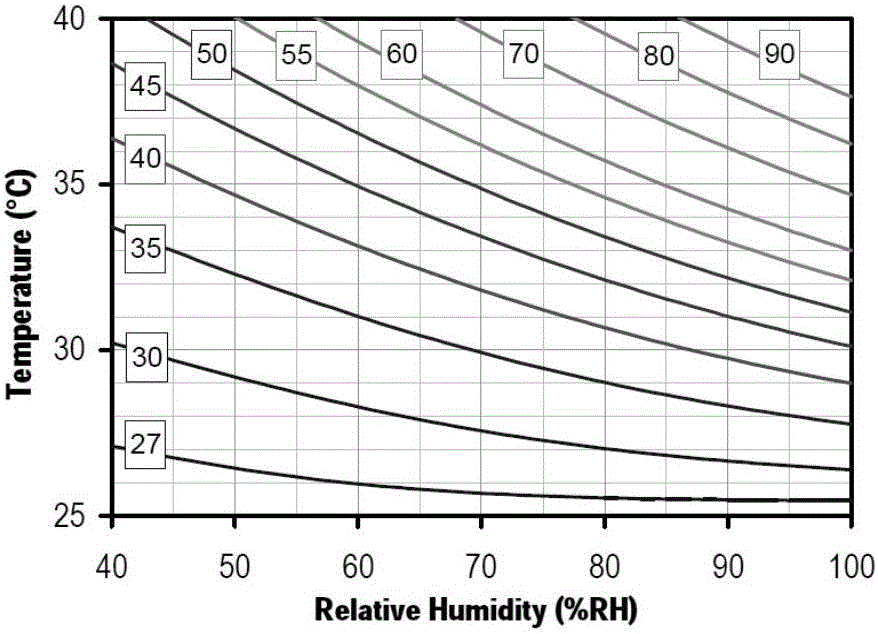

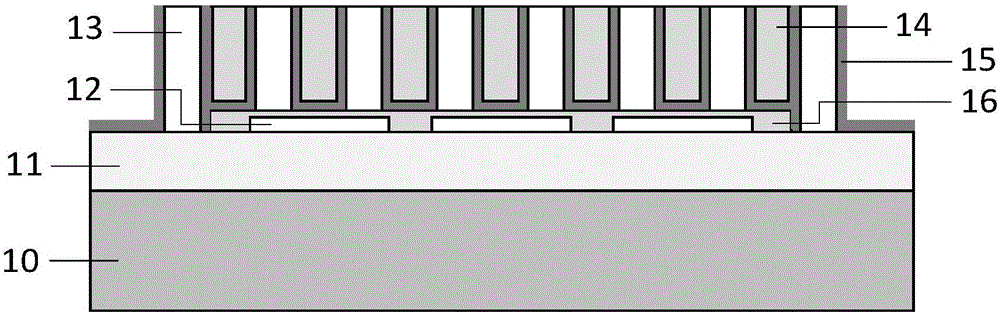

Single-chip high-precision temperature and humidity sensor

ActiveCN106768050AAvoid temperature effectsReduce technical errorThermometers using electric/magnetic elementsUsing electrical meansCapacitanceElectrical resistance and conductance

The invention discloses a single-chip high-precision temperature and humidity sensor. A heat conduction channel layer is arranged on the top of a chip and serves as a temperature sensitive resistor of a temperature sensor to perceive temperature of external environments, temperature influence caused by a substrate, a PCB (printed circuit board) connected with the substrate and the like can be avoided when the temperature sensitive resistor perceives the temperature of the external environments, so that the temperature under the external humidity can be accurately reflected, and technical errors can be greatly reduced when the single chip is integrated. The temperature and humidity sensor is integrated onto a shared substrate in an embedded manner and shares a forked capacitance electrode plate, so that the temperature and humidity sensor has a smaller area and suitable for manufacture of needlelike sensors, the temperature and humidity sensor is parallelly integrated onto the shared substrate, so that the temperature and humidity sensor can be thinner and is suitable for manufacture of thin sensors, and the temperature and humidity sensor can be widely applied to occasions of different specific requirements.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

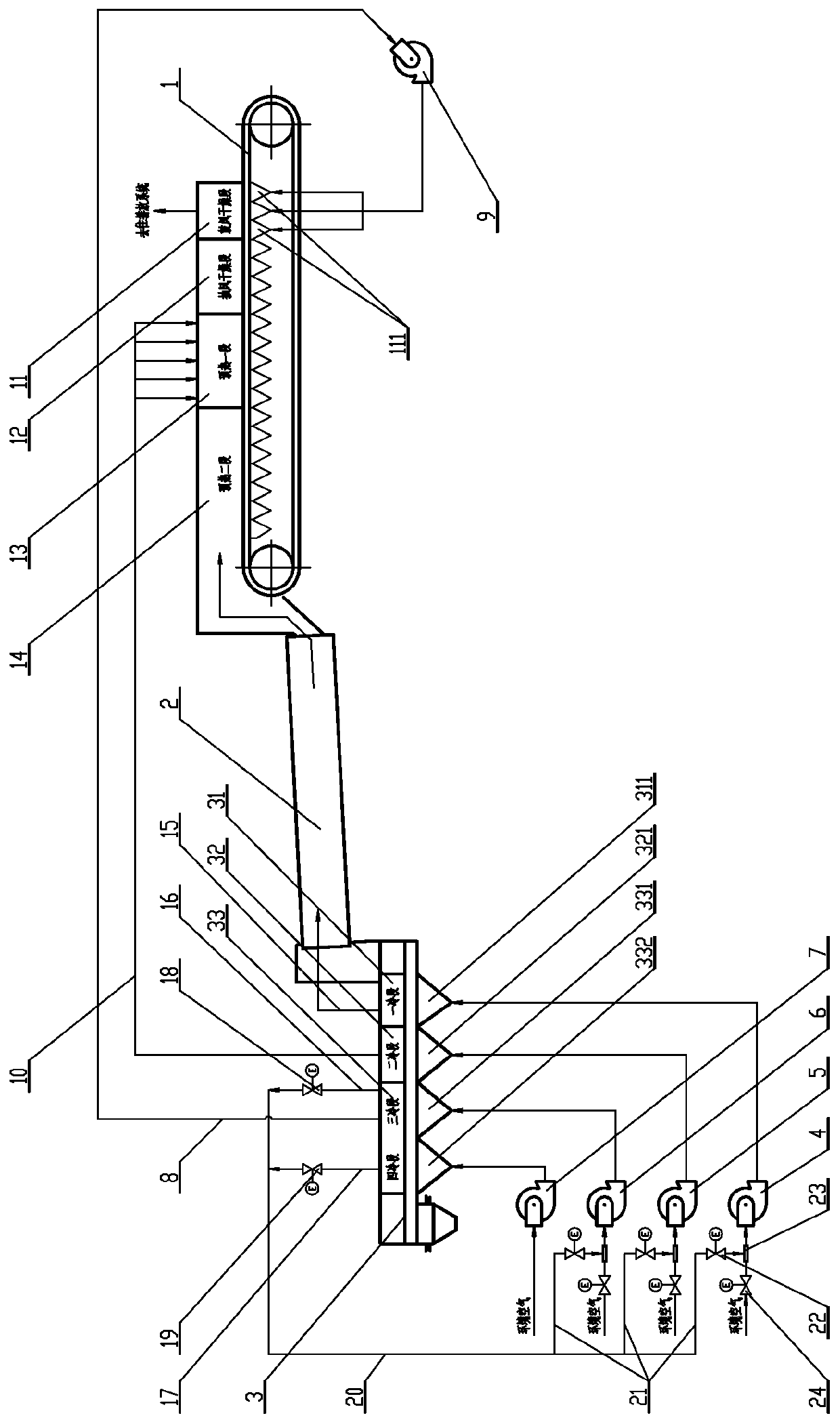

Pellet cooling exhaust gas recycling and utilizing system and using method

ActiveCN110157903AAvoid temperature effectsGuaranteed air drying effectRotary drum furnacesHeat lossesEngineering

The invention relates to a using method of a pellet cooling exhaust gas recycling and utilizing system. A chain grate, a chain grate upper cover, an air bellow of the chain grate upper cover, a rotarykiln, a ring cooler, a ring cooler upper cover, an air bellow of the ring cooler upper cover, a cooling fan, a dry air blowing machine, a pipeline and a valve are included. The using method is characterized in that a third cold section upper cover and a fourth cold section upper cover of the ring cooler communicate with each other to form a cooling rear section upper cover, and the cooling rear section upper cover is connected with a cooling exhaust gas temperature adjustment system. The cooling exhaust gas temperature adjustment system includes an exhaust pipe I, an exhaust pipe II, an exhaust pipe III, a regulating valve I, a regulating valve II, a cooling exhaust gas returning main pipe, three cooling exhaust gas returning branch pipes and a regulating valve III. The using method has the advantages that exhaust gas of pellet cooling links is totally recycled and used, the heat loss is reduced, the energy consumption of the system is reduced, the temperature adjustment means of theexhaust gas is provided, and hot airflow at the appropriate temperature is provided to the chain grate and the rotary kiln to serve as a heat source.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

SOQ-based flexible lever amplification vibration beam accelerometer chip, and processing technology thereof

ActiveCN109100535AResolving Stress Match InconsistenciesReduce the problem of inconsistent stress matchingAcceleration measurement using interia forcesAccelerometerEngineering

The invention provides an SOQ-based flexible lever amplification vibration beam accelerometer chip, and a processing technology thereof. The SOQ-based flexible lever amplification vibration beam accelerometer chip comprises a quartz structure and a silicon-based structure, which are bonded together, wherein the quartz structure is a same plane differential quartz vibration beam chip structure composed of a quartz frame, an inertia force input end, a flexible lever, a quartz tuning fork, a flexible hinge, a mass block, a connecting rod and an etching gap; the silicon-based structure comprises asilicon-based frame and a release groove; the processing technology comprises: firstly, processing the release groove of the silicon-based structure of a silicon wafer, bonding the silicon wafer witha quartz plate, then thinning and polishing the quartz plate to fabricate the quartz structure, and finally scribing by using a scribing machine; an inertia force generated by the mass block under the influence of acceleration is transferred onto the lever by the inertia force input end for amplification, the force is concentrated by the connecting rod and is uniformly distributed to two vibration beams of the quartz tuning fork, the tension frequency of the quartz tuning fork on both sides of central symmetry is increased, the compression frequency of the other side is reduced, and the acceleration is measured by the frequency difference change; and the chip provided by the invention has the advantages of small volume, high precision, etc.

Owner:XI AN JIAOTONG UNIV

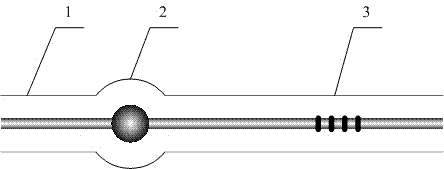

Micro-displacement sensor based on spherical optical fiber and Bragg grating cascade

Disclosed is a micro-displacement sensor based on spherical optical fiber and Bragg grating cascade. An incident end single-mode optical fiber, the spherical optical fiber and a Bragg grating are serially connected to form the micro-displacement sensor, the diameter of the spherical optical fiber ranges from 160 micrometers to 180 micrometers, and the distance between the spherical optical fiber and the Bragg grating is shorter than 2cm. The micro-displacement sensor has the advantages that micro-displacement is measured by the aid of the micro-displacement sensor based on spherical structure and Bragg grating cascade, treatment such as corrosion and grinding needed by a traditional grating sensor is avoided, manufacturing difficulty and cost are reduced, micro-displacement measuring sensitivity is effectively improved by measuring the power of a reflection peak of a grating backward cladding mode, the sensor cannot be affected by temperature, stability is improved, and the micro-displacement sensor is compact in design, convenient to use and low in cost.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

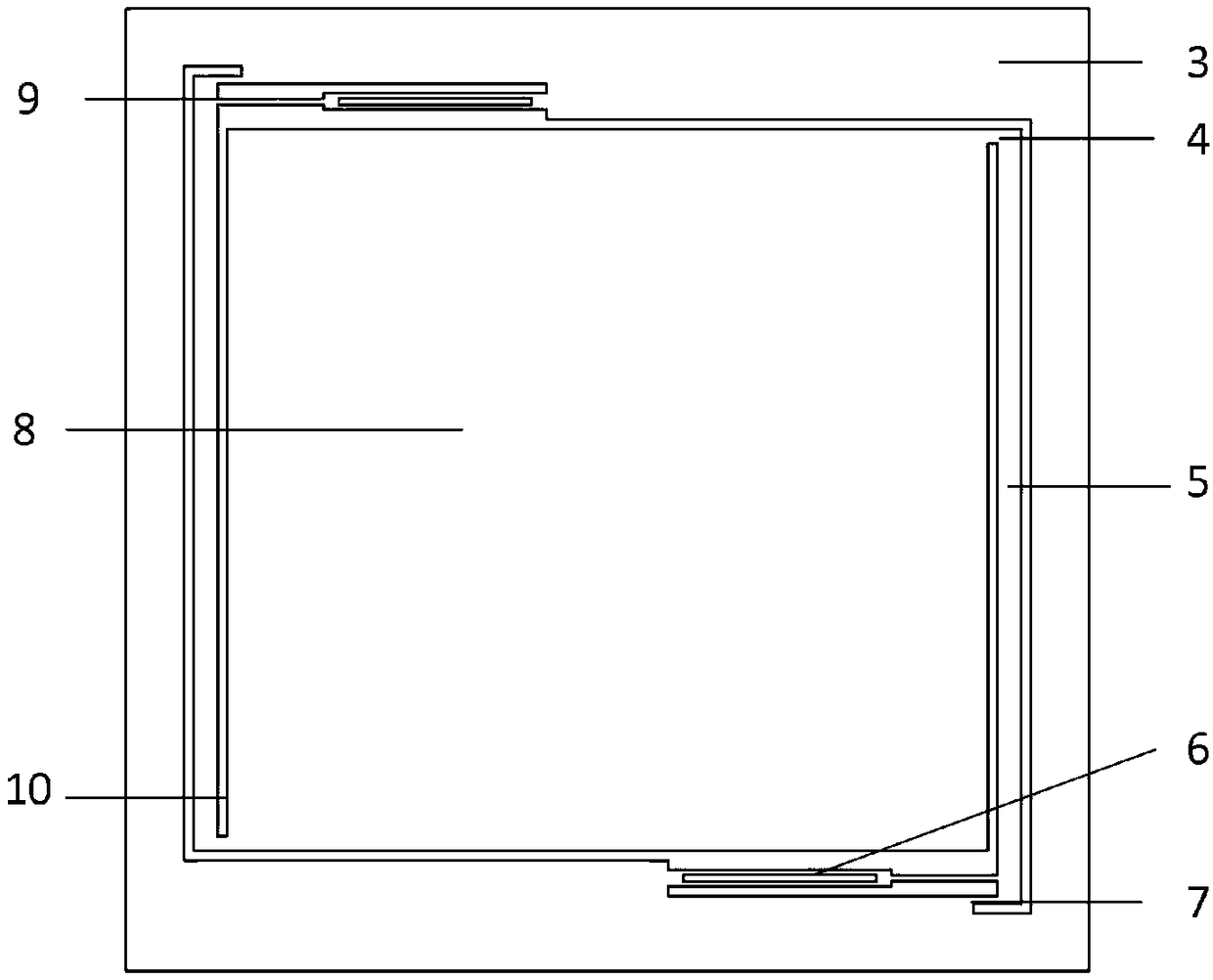

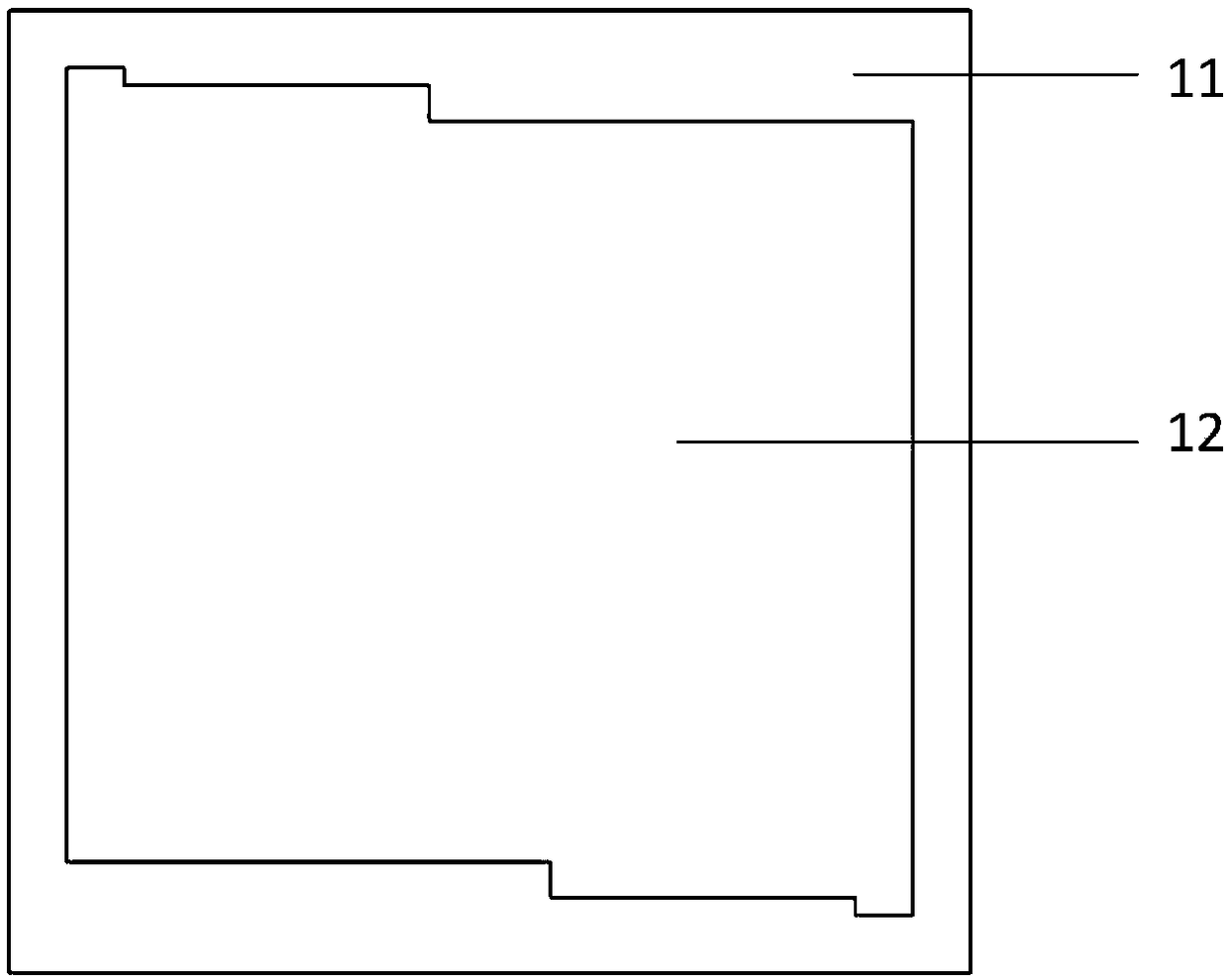

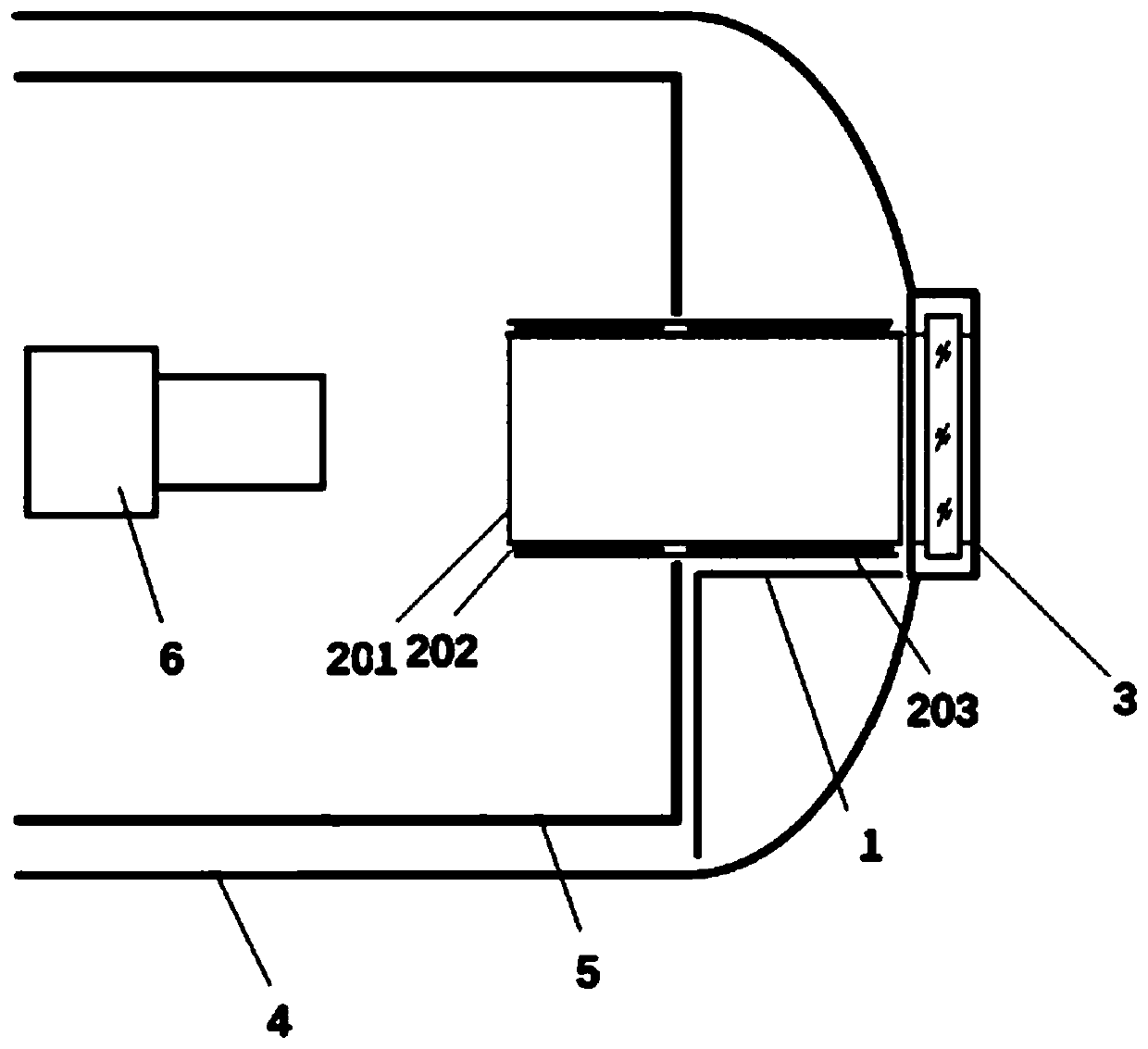

Temperature control device and method for optical window of space environment simulator

PendingCN111405687AEasy temperature controlAvoid temperature effectsCosmonautic condition simulationsOhmic-resistance heatingTemperature controlOptical test

The invention relates to a temperature control device and a temperature control method, in particular to a temperature control device and method for an optical window of a space environment simulator,which are suitable for optical index testing of a space camera ground thermo-optical test. The invention provides the temperature control device and method for an optical window of a space environment simulator to solve the technical problems that an existing temperature control device for the optical window of the space environment simulator is large in size and poor in temperature control effect or a heating film is pasted to influence an optical test result. The device comprises a mounting bracket, a control unit and a cylindrical heating unit, the mounting bracket is arranged at the bottom of the heating unit; the heating unit sequentially comprises a heating cylinder, an electric heating layer and a multi-layer heat insulation assembly from inside to outside. Spaceflight black paintis sprayed on the inner surface of the heating cylinder; the electric heating layer is formed by sticking a thin film type electric heating sheet along the circumferential surface of the outer side ofthe heating cylinder; and the film type electric heating sheets are divided into multiple groups for independent heating along the axial direction of the heating cylinder. According to the method, the device is used for controlling the temperature of the optical window.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

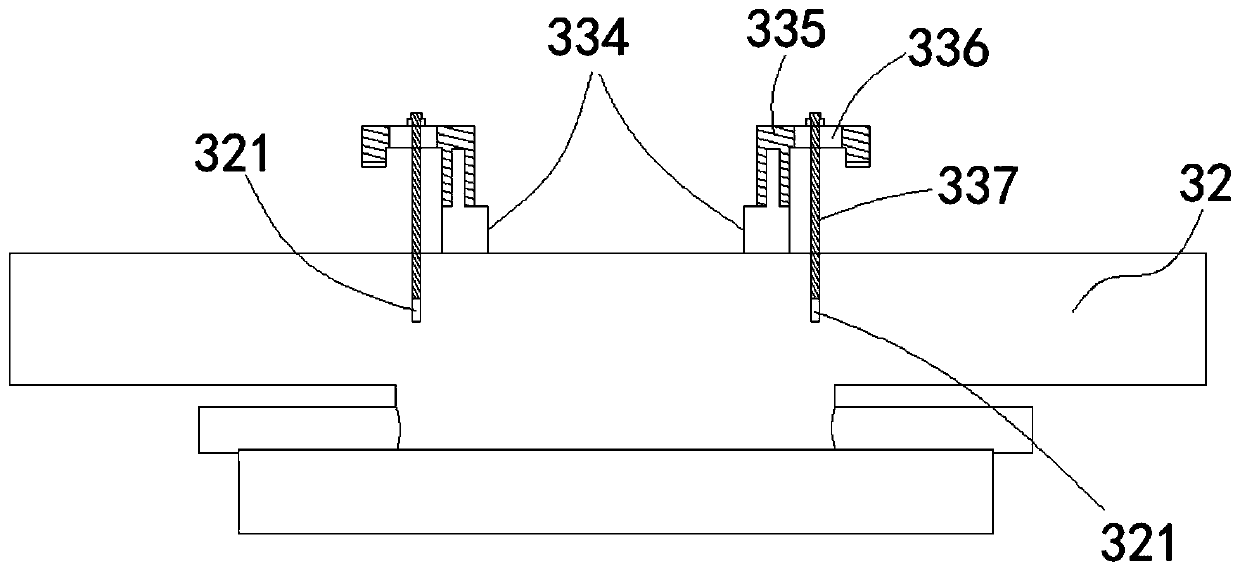

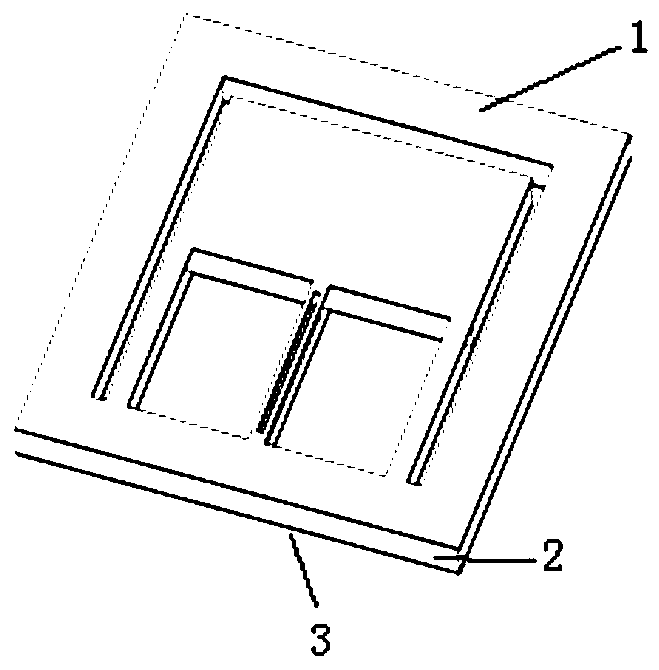

Precision part machining numerical control machine tool

PendingCN111168474AShorten the lengthGuaranteed rigidityDispersed particle filtrationTransportation and packagingNumerical controlProcess engineering

The invention discloses a precision part machining numerical control machine tool. The precision part machining numerical control machine tool comprises a machining chamber with an inner cavity. A workpiece machining device and a workpiece fixing and rotating mechanism are arranged in the machining chamber. The workpiece machining device comprises a moving mechanism and a turret capable of being driven to move and rotate by the moving mechanism. A plurality of machining tools are arranged on the turret. Cutting edges of at least two of the machining tools have the height difference. At least part of the machining tools of which the cutting edges have the height difference are detachably connected with the turret through different lengths of tool aprons. According to the precision part machining numerical control machine tool, the machining tools are fixed to the turret through the tool aprons with the different lengths; the requirement for the low position of the cutting edges of the machining tools can be met through the tool aprons; and accordingly, the length of the machining tool can be greatly reduced to ensure the rigidity of the tools, and the machining stability and qualitycan be improved.

Owner:昂拓科技(苏州)有限公司

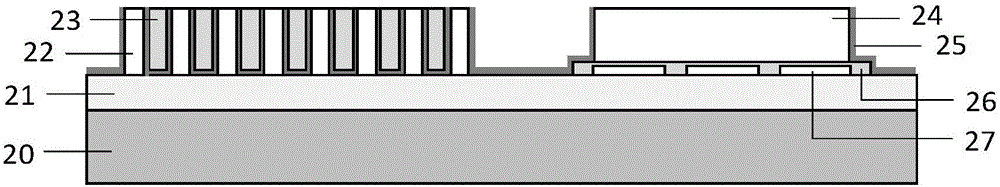

Chip of Z-direction sensitive quartz vibration beam accelerometer based on quartz on silicon (QoS) technology, processing technology and accelerometer

ActiveCN109765404AIsolation from temperature effectsAvoid temperature effectsAcceleration measurementAccelerometerQuartz

The invention provides a chip of a Z-direction sensitive quartz vibration beam accelerometer based on a quartz on silicon (QoS) technology, a processing technology and an accelerometer. The chip comprises a first quartz structure and a second quartz structure, wherein the first quartz structure and the second quartz structure are bonded on two sides of a silicon substrate structure; the quartz structures comprise quartz frames, two-end fixed quartz tuning forks, quartz supporting beams and quartz mas blocks; the silicon substrate structure comprises a silicon substrate frame and a silicon massblock; a sandwich form of the first quartz structure, the silicon substrate structure and the second quartz structure is formed and completely bonded at the quartz frame and the silicon substrate frame and the quartz mass block and the silicon mass block; and the processing technology comprises the steps that firstly, initial processing of the silicon substrate is carried out, then double-surfacebonding of the silicon substrate and two quartz pieces is carried out, the two quartz pieces are subjected to thinning and polishing, then quartz vibration beam electrodes and the quartz structures are manufactured, and finally the silicon substrate structure is released. The chip of the Z-direction sensitive quartz vibration beam accelerometer has the characteristics that the sensitivity is high, the cost is low and the like.

Owner:XI AN JIAOTONG UNIV

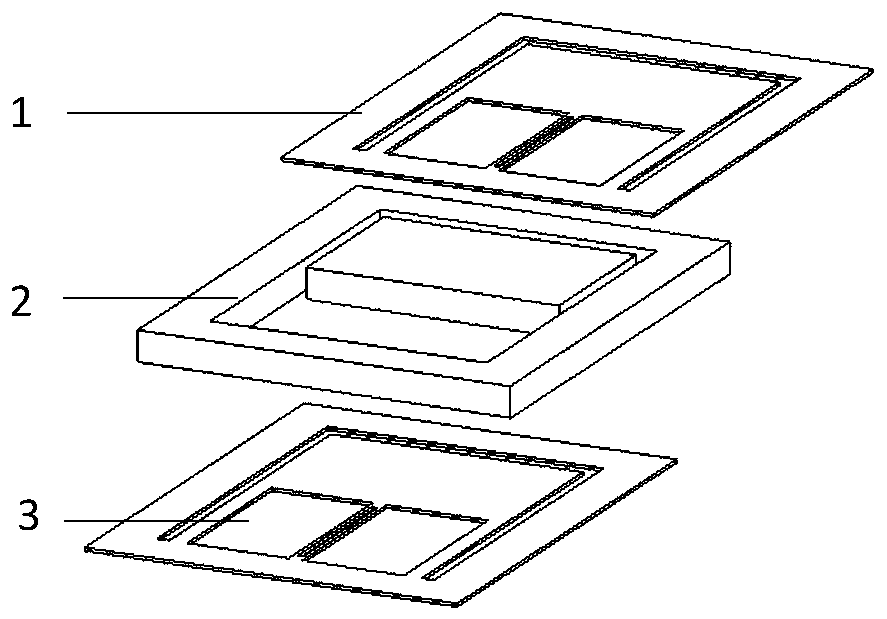

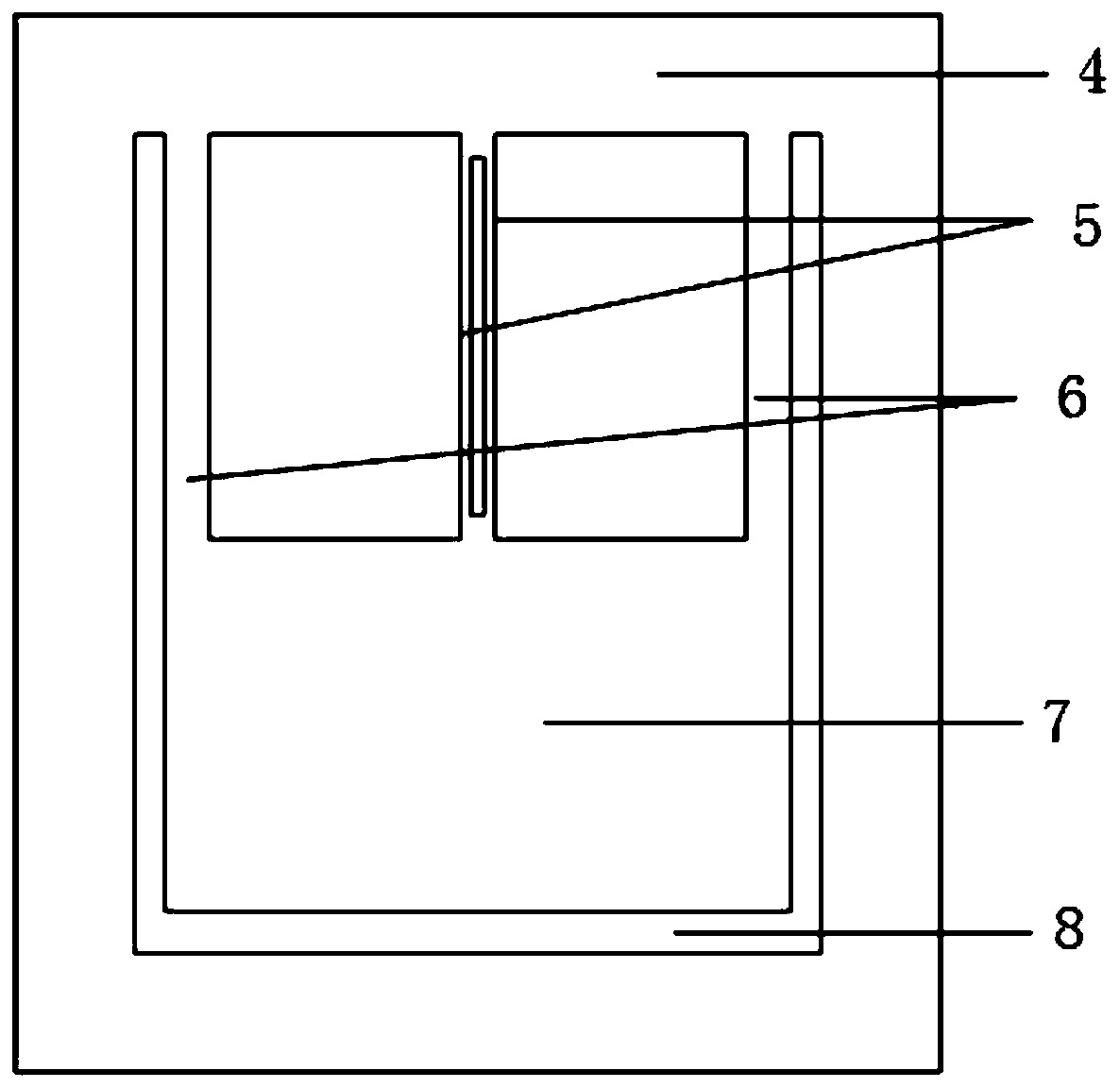

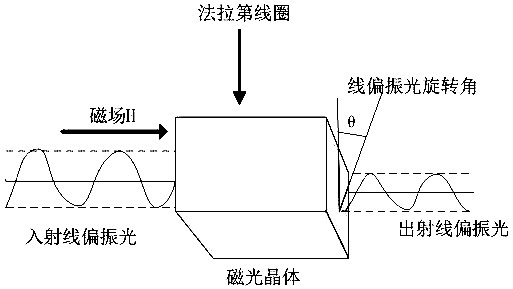

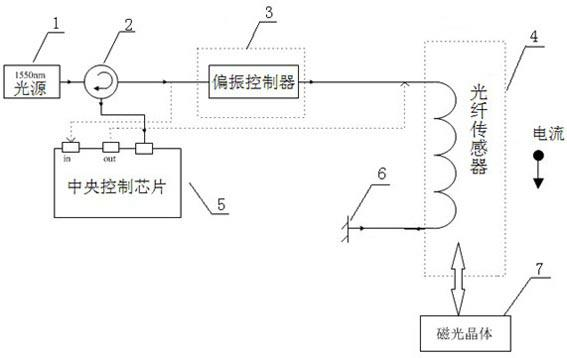

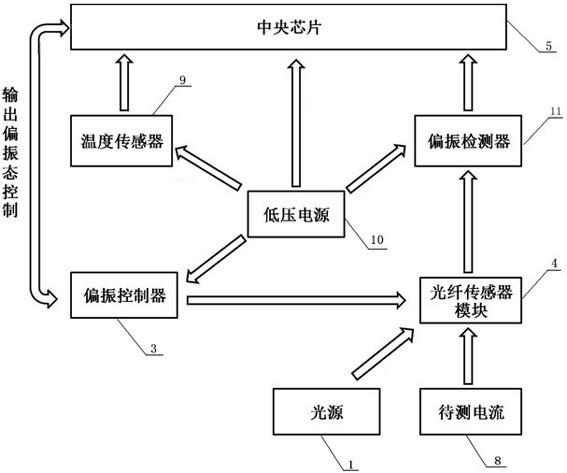

Environment temperature compensation heavy current measurement system based on fiber polarization detection

InactiveCN102590608ASimple structureRealize long-distance transmissionCurrent/voltage measurementReaction rateRates reactions

The invention relates to an environment temperature compensation heavy current measurement system based on fiber polarization detection. Through carrying out real-time measurement on environment temperature, setting a polarization controller, and inputting an optical signal and a temperature signal in the polarization controller simultaneously, a temperature change signal is compensated in the polarization controller, thus the optical signal always maintains linear polarization at a controller output terminal (a fiber which detects current), influence of temperature change on polarization change of light is avoided, influence of the temperature change on a current detection result is avoided, and measurement accuracy of the system is raised. According to the invention, a structure is simple, a requirement of an insulation device is not high, compared with a traditional test system, a dimension becomes smaller, and cost is low. A magneto-optical effect principle is employed, thus a dynamic scope is very large, reaction rate is high, and a non-saturation test of heavy current can be realized. By employing the fiber as a sensor, long distance transmission of data can be realized, and security is raised greatly.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

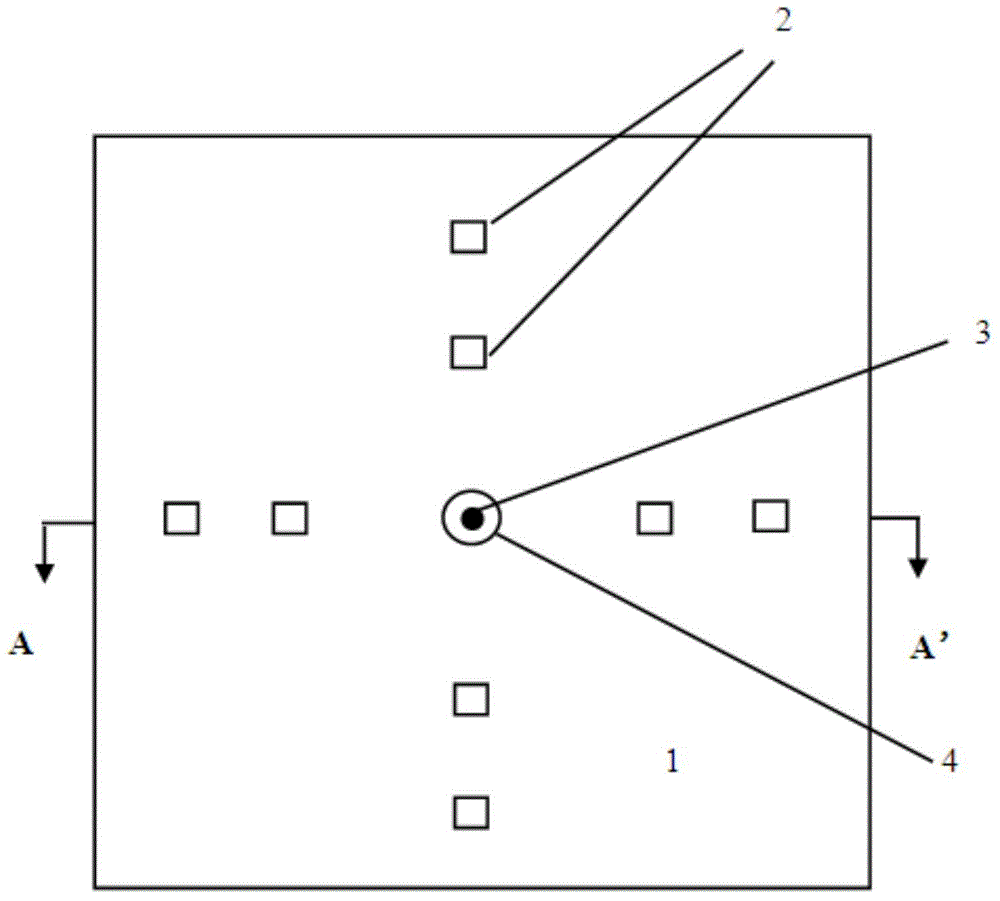

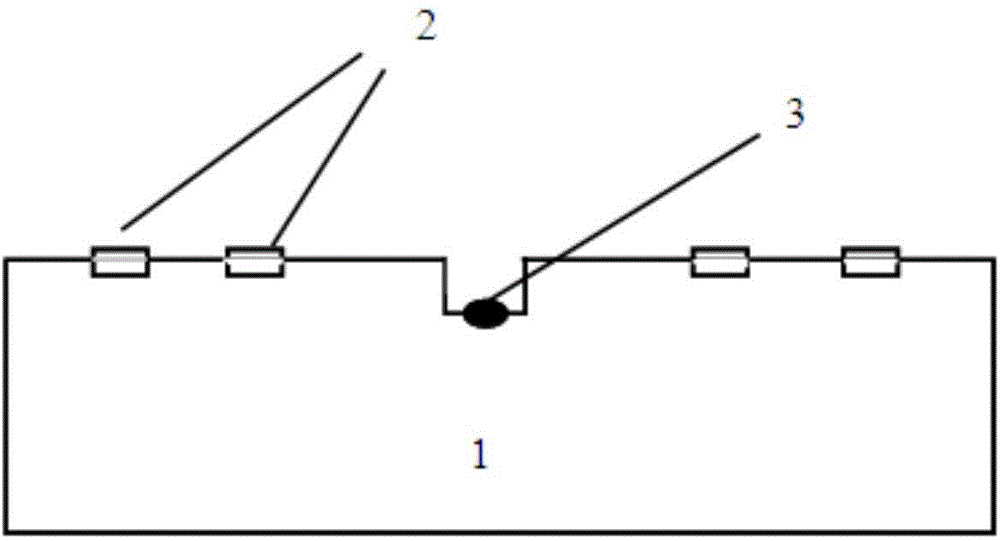

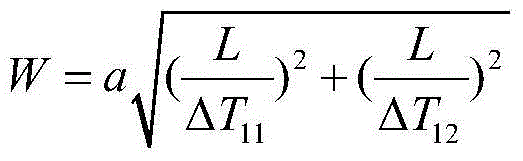

Delay-measurement-based hot wind speed sensor structure and wind speed and direction measuring method

ActiveCN104535793AAvoid direct radiationImprove anti-interference abilityIndication/recording movementFluid speed measurement using thermal variablesAnti jammingMeasurement point

The invention discloses a delay-measurement-based hot wind speed sensor structure and a wind speed and direction measuring method. The hot wind speed sensor structure comprises a substrate; if an XOY rectangular coordinate system is established on the upper surface of the substrate, a groove is formed in the position of an original point O, and the groove is internally provided with a pulsed heat source; and the positive and negative directions of an X-axis as well the positive and negative directions of a Y-axis are respectively provided with a group of temperature measuring points, wherein each group of temperature measuring points comprises two temperature measuring points which are respectively marked as a first temperature measuring point and a second temperature measuring point, the distances from the four first temperature measuring points to the original point O are equal, the distances from the four second temperature measuring points to the original point O are equal, and each temperature measuring point is provided with a temperature sensor. The wind speed and direction are measured through measuring the time difference of temperature signals received by the temperature sensor, so that the influences of the heat source and environmental temperature to measurement can be avoided; and the delay-measurement-based hot wind speed sensor structure has the advantages of high precision, strong anti-jamming capability, low power consumption, super-miniaturization and the like.

Owner:SOUTHEAST UNIV

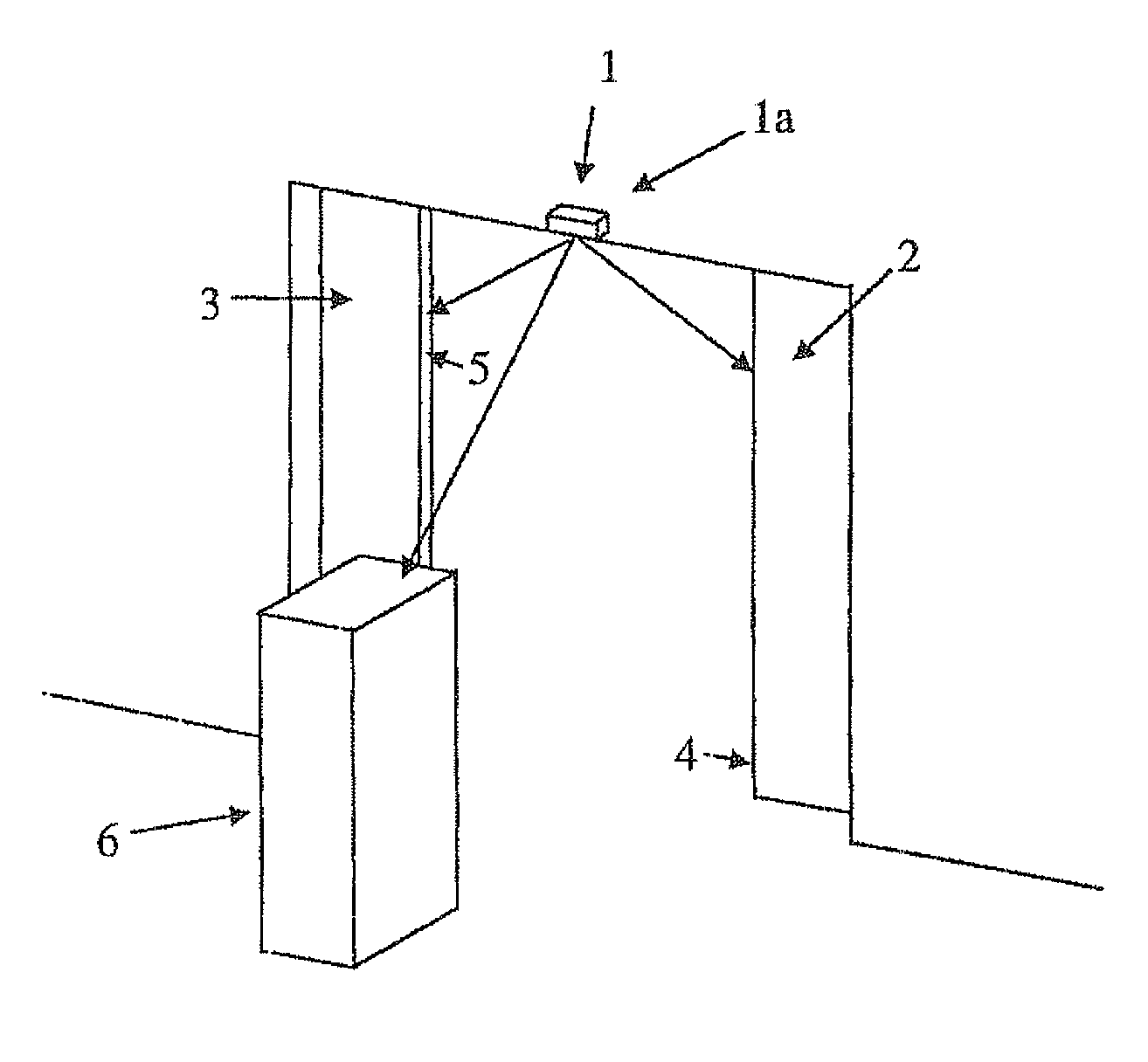

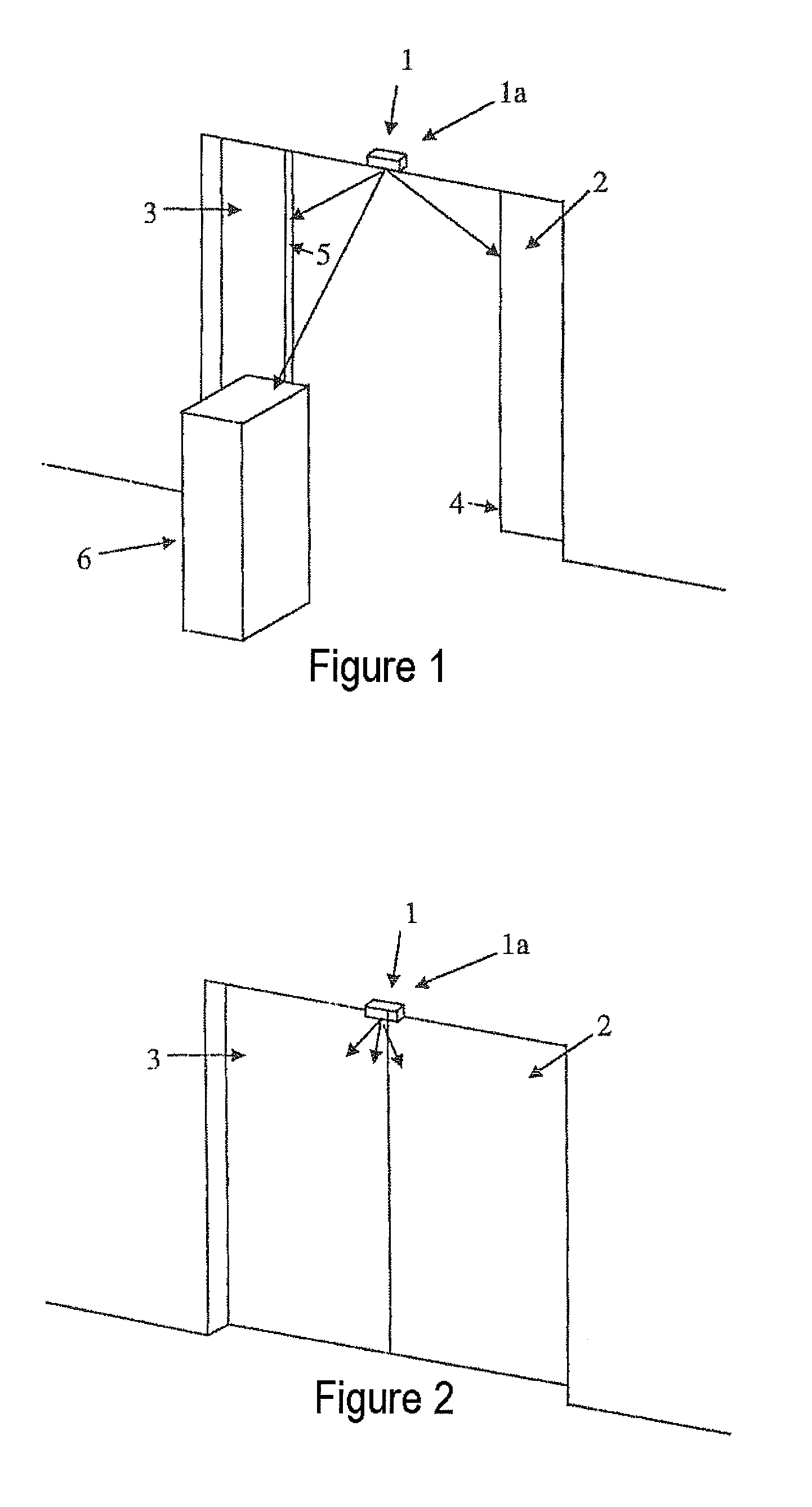

Sensor device

ActiveUS20080225263A1Avoid temperatureAvoid temperature effectsOptical rangefindersPower-operated mechanismPropagation timeElectromagnetic radiation

A sensor device including a source for electromagnetic radiation, a receiver and a control device, the control device being designed for emitting electromagnetic radiation by means of the source and for determining a distance that is covered by the electromagnetic radiation emitted by the source from a reflection surface of an object to the receiver, doing so by evaluating a propagation time of the radiation or a phase of an oscillation modulated onto the radiation. According to the invention, the control device provides an economy mode in which the power of the source is lower in a prescribed time interval by comparison with a normal object detection mode, means being provided to ensure switching back into the normal object detection mode in the event of a predefined object situation.

Owner:CEDES AG

Liquid heater for analyzer

ActiveCN105911299ASlow down the speed of disseminationReduce lossHeating or cooling apparatusMaterial analysisFluid warmerChemistry

Owner:LEADWAY HK

Preparation method of activated carbon with low ash content and high specific surface area

PendingCN111847449AGuaranteed StrengthLarge specific surface areaCarbon compoundsActivated carbonAdhesive

The invention relates to a preparation method of activated carbon with low ash content and high specific surface area. The preparation method comprises the following steps of: S1, selecting coal withash content lower than 8%, and grinding the coal to 200 meshes or below; S2, selecting shell carbonized materials, and crushing and grinding the shell carbonized materials into powder of 200 meshes orbelow; S3, premixing the coal and the shell carbonized materials in the steps S1 and S2 with an adhesive according to a mass ratio of 100: (10-100): (20-60) to form a premix; S4, uniformly mixing andkneading the premix under the condition of 45-120 DEG C, carrying out extrusion molding under the condition of 10-20MPa to form strips with the diameter of 4-12 mm, and airing the material strips; S5, carbonizing the aired material in a carbonizing furnace at the carbonizing temperature of 250-500 DEG C for 0.5-5 hours; and S6, activating the strongly carbonized material for 0.5-5 hours by utilizing water vapor at 800-1100 DEG C to obtain the activated carbon with low ash content and high specific surface area. The activated carbon prepared by the preparation method of activated carbon with low ash content and high specific surface area has the characteristics of low cost, high strength, low gray scale and high specific surface area.

Owner:INNER MONGOLIA PURUIFEN ENVIRONMENTAL SCI ANDTECH

Digital display temperature-controlled control cabinet

InactiveCN105451524AEasy to moveConvenient locationAuxillary controllers with auxillary heating devicesModifications using gaseous coolantsTemperature controlElectricity

The invention discloses a digital display temperature-controlled control cabinet. The digital display temperature-controlled control cabinet comprises a box body, wherein a left-leaf door and a right-leaf door which can be opened and closed are arranged on a front side of the box body; a hook lock is arranged on the left-leaf door; a storage battery is fixedly arranged inside the box body; the storage battery is connected with a power line; the storage battery is connected with a light-emitting diode (LED) lamp through a deformable coiled pipe with a hollow structure; an electric line between the storage battery and the LED lamp is embedded into a cavity of the coiled pipe; outer surfaces of the storage battery, the coiled pipe and the LED lamp are provided with insulators; a heat dissipation fan for dissipating heat is arranged on a side face of the box body; the heat dissipation fan is electrically connected with an AT89S52 single-chip microcomputer arranged in the box body; the AT89S52 single-chip microcomputer is also electrically connected with a temperature sensor arranged in the box body; the AT89S52 single-chip microcomputer is also electrically connected with a liquid crystal display (LCD) which is arranged on the right-leaf door of the box body and used for displaying a temperature detected by the temperature sensor; and wheels are arranged at the bottom of the box body.

Owner:天津市鹏源电器科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com