Ultrasonic flux detection system and detection method

A flow detection and ultrasonic technology, which is used in high-precision fluid flow ultrasonic detection systems and detection fields, can solve problems such as high measurement accuracy requirements, great influence, and measurement stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

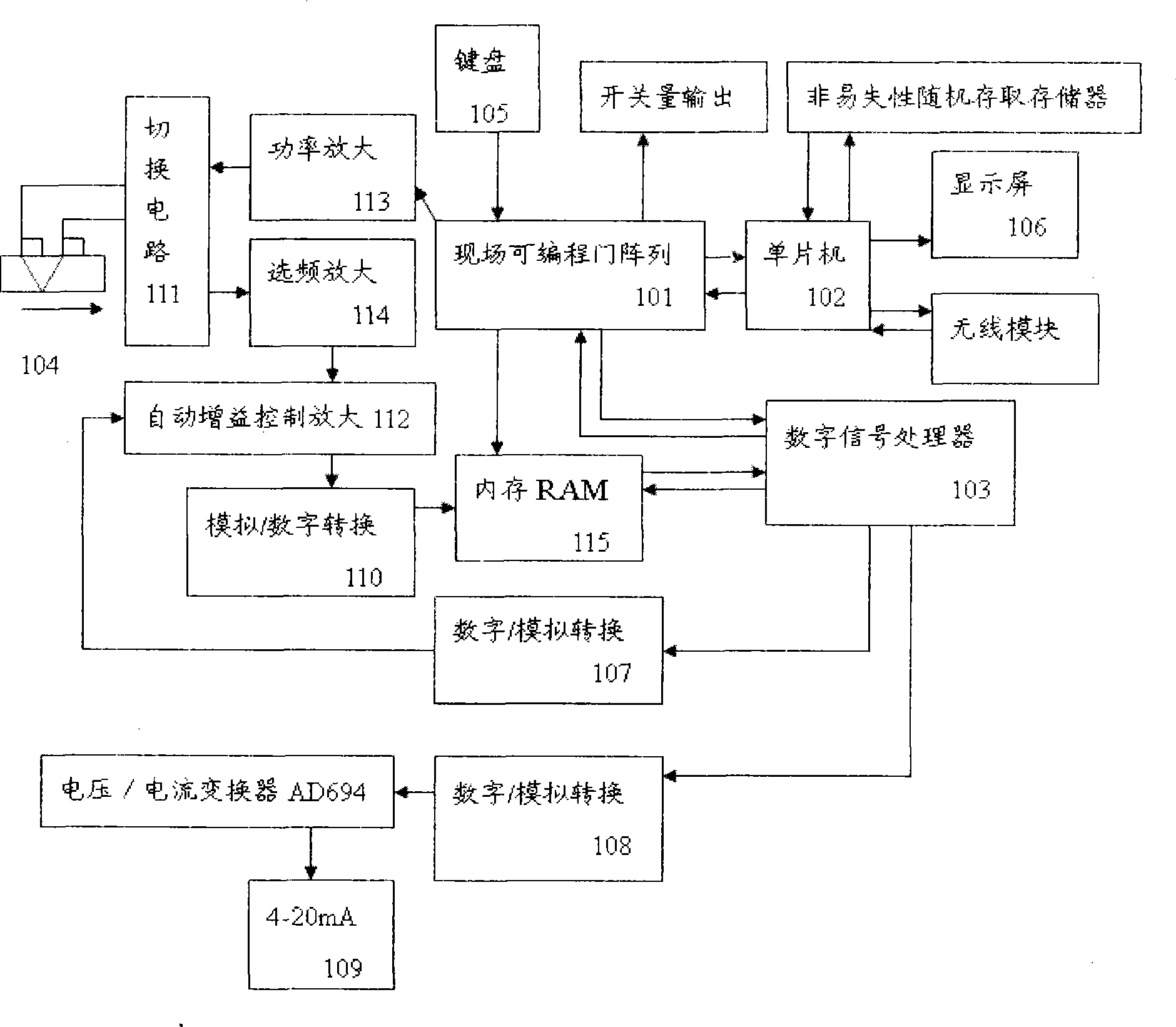

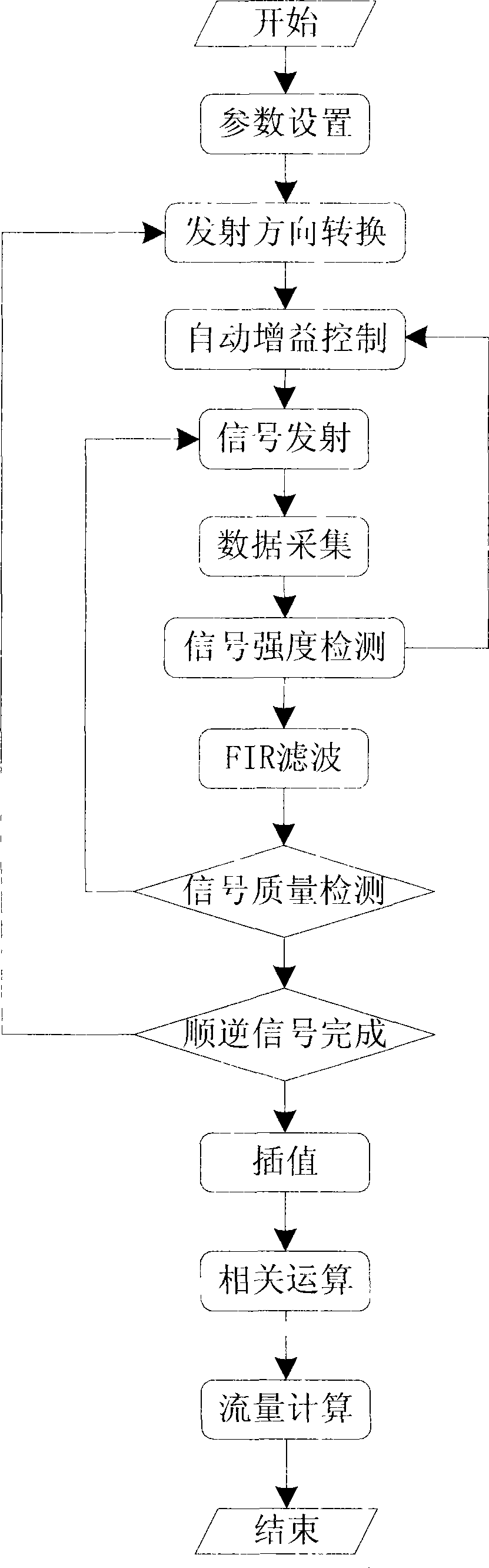

[0022] The description process can be found in figure 1 Structural schematic diagram of ultrasonic flow detection system in an ultrasonic flow detection system and detection method of the present invention and figure 2 Flow chart of ultrasonic flow detection method.

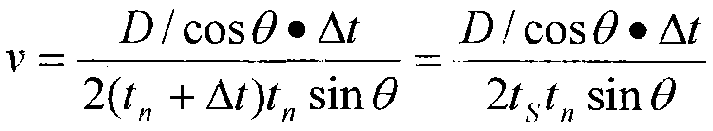

[0023] The working principle of the ultrasonic flow detection system is that the first ultrasonic transducer 104 and the second ultrasonic transducer 104, under the control of the field programmable gate array 101, work alternately in the transmitting and receiving states, and the resonance frequency is 1MHz. The received signal is filtered by the frequency selection amplifier 114 to filter out some interference signals, and then amplified by the automatic gain control 112 and then sent to the analog / digital converter 110. The analog / digital conversion is realized at a conversion speed of 25 n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com