High-speed wax coating apparatus

A waxing device and high-speed technology, applied in the direction of paper, etc., can solve the problems of insufficient high-speed operation, accumulation, shedding, contamination of packaged food, etc., and achieve the effect of ensuring uniformity and uniform waxing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

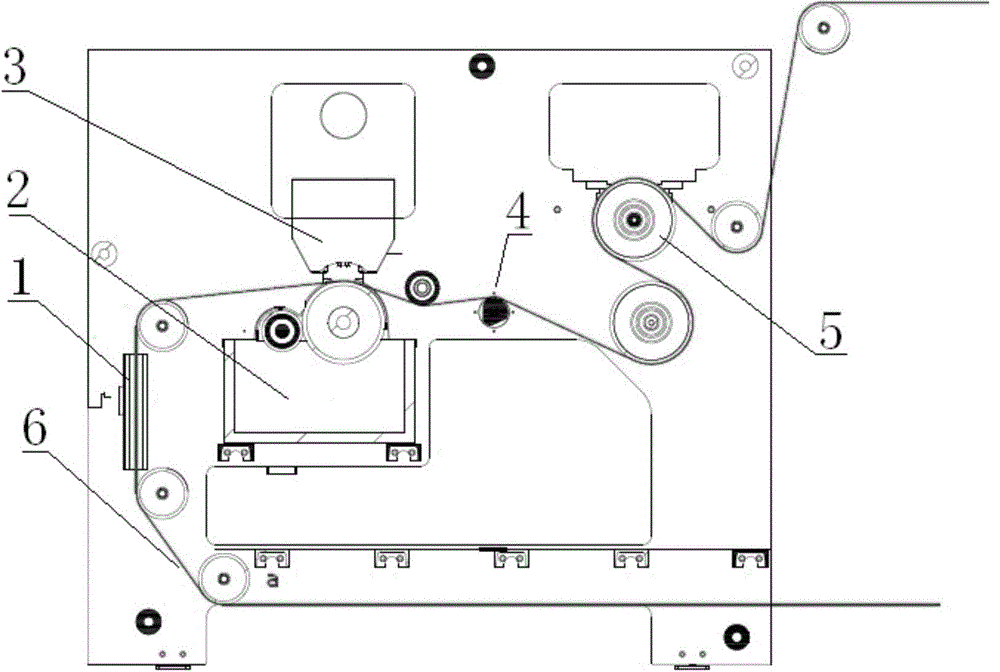

[0029] A high-speed waxing device, its structure is as figure 1 As shown, it mainly includes a base paper preheating component 1, a wax melting chamber component 2, a waxing component 3, a wax rubbing roller 4, and a cooling roller 5. The base paper preheating component 1 is used for preheating the base paper before waxing. The wax melting cavity component 2 is arranged at the rear of the base paper preheating component 1, and contains the preheated base paper that is transmitted to the cavity for coating. wax liquid wax. The wax-melting chamber assembly 2 is an integrated double wax box, which can avoid the influence of the process of adding wax particles on the temperature of the melted wax in the whole wax box on the one hand, and can also carry out two-stage heating on the filled wax liquid on the other hand. The waxing component 3 is a disc structure, the lower part is soaked in the wax melting cavity component 2, and the wax liquid is coated on the base paper by rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com