Micro-displacement sensor based on spherical optical fiber and Bragg grating cascade

A technology of micro-displacement sensors and Bragg gratings, applied in instruments, optical devices, measuring devices, etc., can solve the problems of restricting the accuracy of micro-displacement sensors, difficulty in guaranteeing mechanical strength, and irregular geometric dimensions, so as to reduce production difficulty and cost , low cost and compact design

Active Publication Date: 2014-07-23

TIANJIN UNIVERSITY OF TECHNOLOGY

View PDF4 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the geometric size after etching is irregular, the production is complicated, and the repeatability is poor.

The mechanical strength of special light-splitting structures such as eccentric structure, tapered structure, laser etching, etc. is difficult to guarantee and is easy to break

Micro-displacement sensors are generally susceptible to temperature, and cross-sensitivity occurs, which also restricts the accuracy of micro-displacement sensors

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

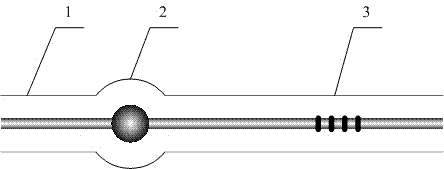

[0022] A micro-displacement sensor based on cascaded spherical optical fibers and Bragg gratings, such as figure 1 As shown, it consists of a single-mode optical fiber 1 at the incident end, a spherical optical fiber 2 and a Bragg grating 3 in series. The diameter of the spherical optical fiber 2 is 160-180 μm, and the distance between the spherical optical fiber 2 and the Bragg grating 3 is <2cm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

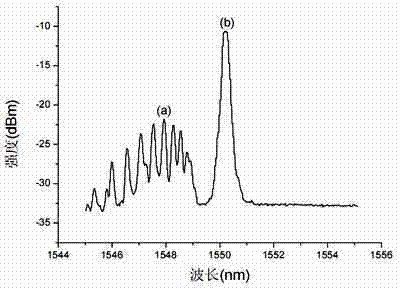

Disclosed is a micro-displacement sensor based on spherical optical fiber and Bragg grating cascade. An incident end single-mode optical fiber, the spherical optical fiber and a Bragg grating are serially connected to form the micro-displacement sensor, the diameter of the spherical optical fiber ranges from 160 micrometers to 180 micrometers, and the distance between the spherical optical fiber and the Bragg grating is shorter than 2cm. The micro-displacement sensor has the advantages that micro-displacement is measured by the aid of the micro-displacement sensor based on spherical structure and Bragg grating cascade, treatment such as corrosion and grinding needed by a traditional grating sensor is avoided, manufacturing difficulty and cost are reduced, micro-displacement measuring sensitivity is effectively improved by measuring the power of a reflection peak of a grating backward cladding mode, the sensor cannot be affected by temperature, stability is improved, and the micro-displacement sensor is compact in design, convenient to use and low in cost.

Description

technical field [0001] The invention belongs to the field of optical fiber sensing, in particular to a micro-displacement sensor based on spherical optical fiber and Bragg grating cascaded. Background technique [0002] With the development of optical fiber communication related fields, optical fiber sensing technology has made great progress. Among them, micro-displacement sensors are widely used in industrial production, environmental safety, and clinical testing. As an important parameter to reflect the state of objects, micro-displacement plays an important role in production practice. There are many micro-displacement methods known at present. Because optical fiber sensors have many advantages such as small size, low cost, anti-electromagnetic interference, high sensitivity and corrosion resistance, optical fiber micro-displacement sensors have aroused widespread interest in the application field. [0003] For conventional fiber grating sensors, the light energy is c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01B11/02

Inventor 童峥嵘袁硕张卫华曹晔

Owner TIANJIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com