Cooking utensil and cooking control method of cooking utensil

A technology of cooking utensils and control methods, applied in the fields of cooking control and cooking utensils, can solve the problems of overflowing rice soup, poor taste of rice, and difficult to clean, and achieves the effect of ensuring uniform heating, sufficient aroma and sweetness, and preventing the breeding of bacteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

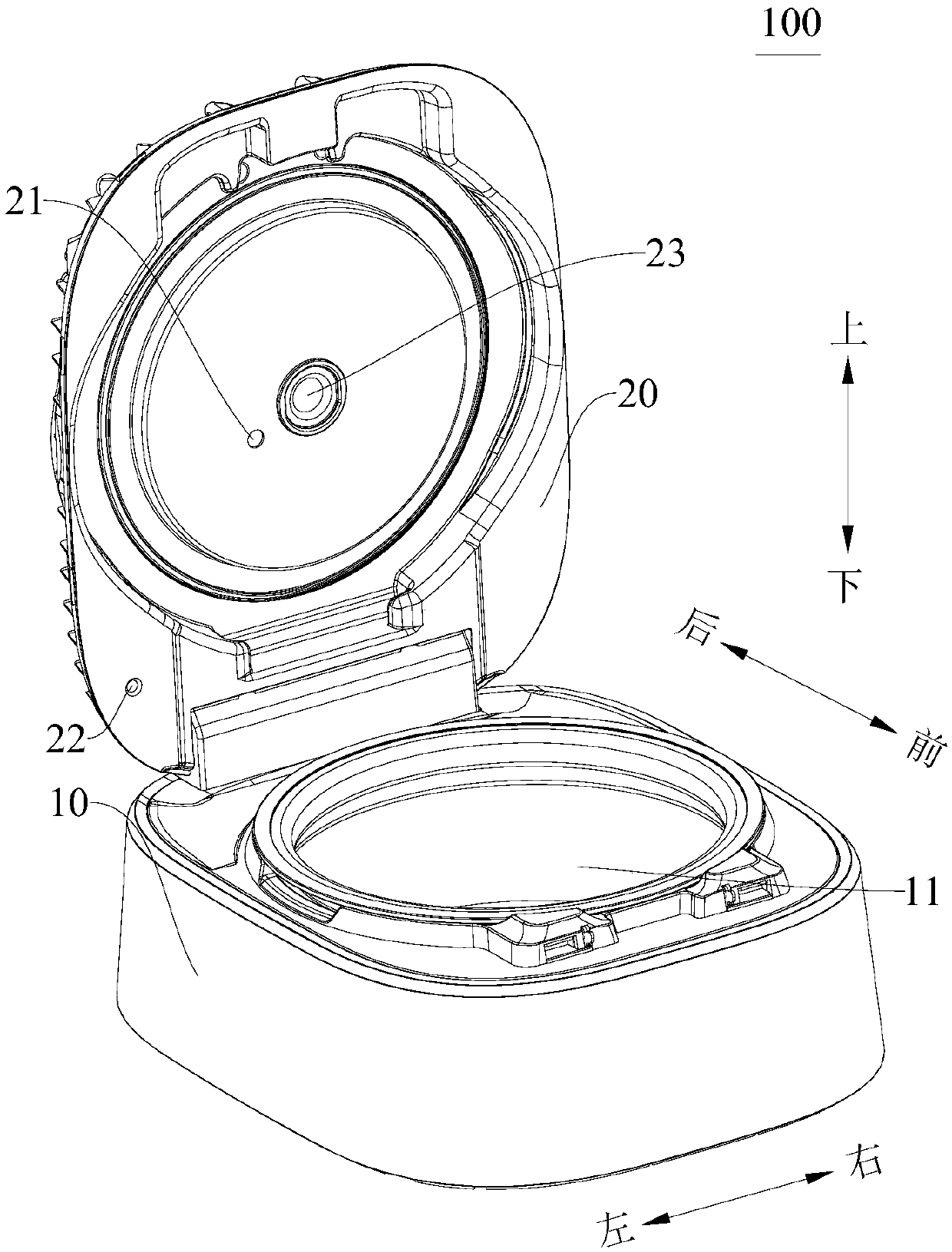

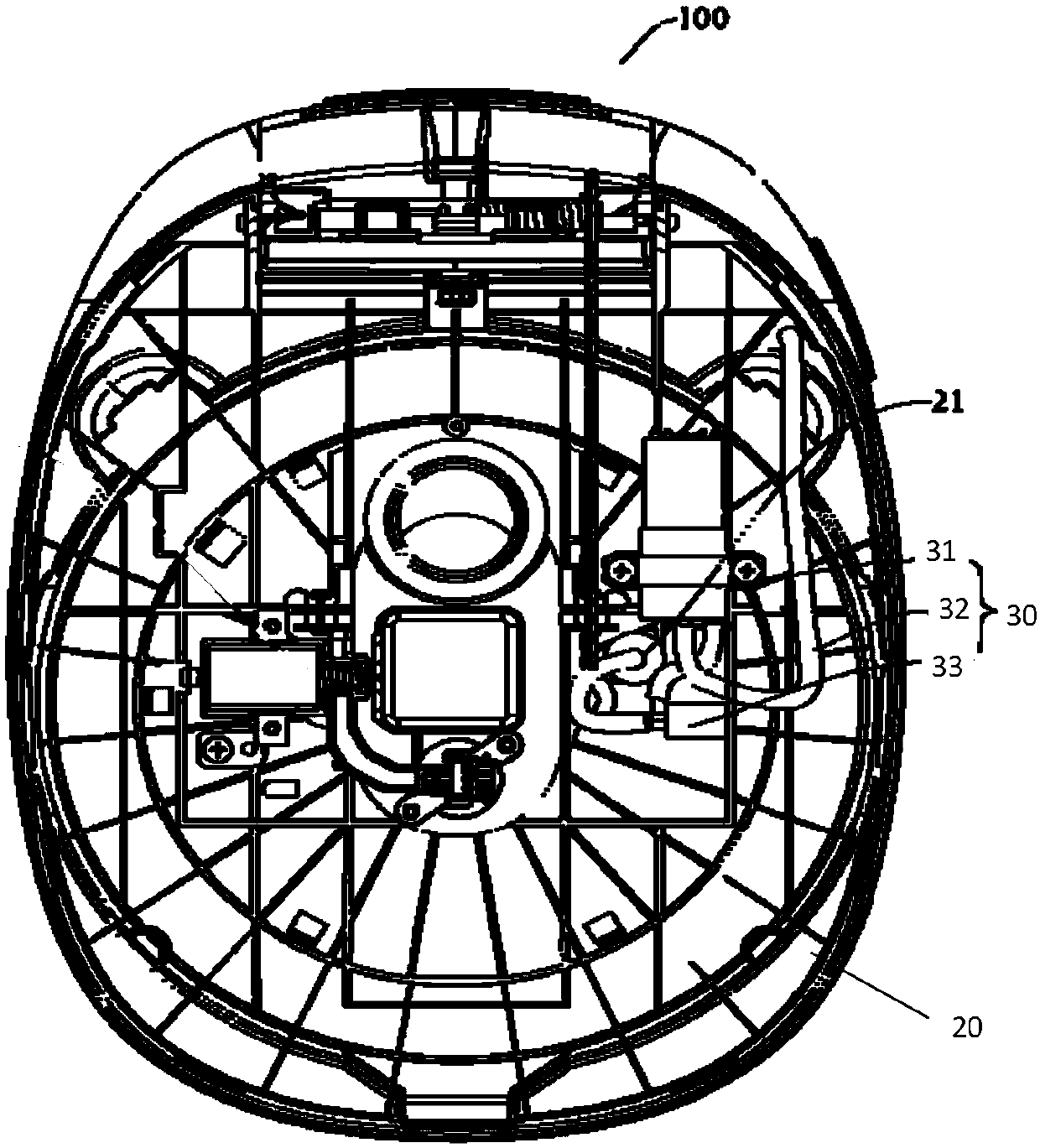

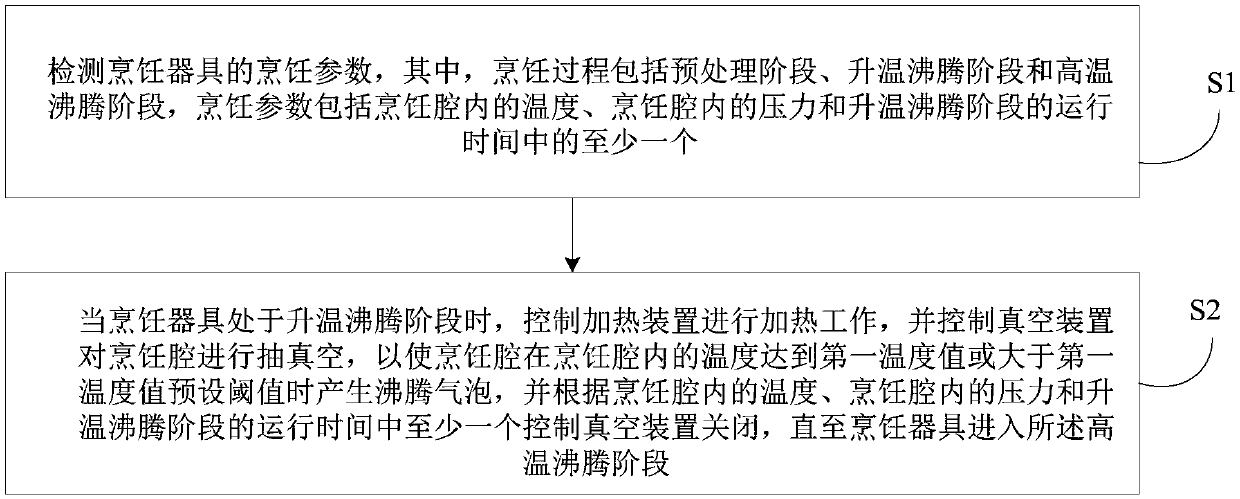

[0288] According to one embodiment of the present invention, when the cooking utensil is in the heating and boiling stage, the vacuum device is controlled to vacuumize the cooking cavity at least once, so that the temperature of the cooking cavity in the cooking cavity reaches or exceeds the first temperature value Boiling bubbles are generated at a preset threshold.

[0289] It can be understood that when the temperature in the cooking cavity reaches the first temperature value such as 55°C, the rice grains are in the stage of gelatinization. At this time, the vacuum device can be controlled to vacuum the cooking cavity at least once to form a negative pressure in the cooking cavity , according to the correspondence between the air pressure and the boiling point, it can be known that the pressure in the cooking cavity decreases, and the boiling point of the rice water decreases accordingly. Therefore, by vacuuming, the rice water can be produced at a lower temperature (before ...

Embodiment 2

[0296] According to an embodiment of the present invention, when the cooking utensil enters the stage of heating up and boiling, the heating device is controlled to perform heating work, and the vacuum device is controlled to vacuumize the cooking chamber at the same time, so that the cooking chamber generates boiling bubbles.

[0297] In the cooking control method of the embodiment of the present invention, in the heating and boiling stage, that is, in the range from the first temperature value to the second temperature value, the vacuum device is controlled to vacuum the cooking cavity so that a negative pressure vacuum is formed in the cooking cavity, so that The boiling temperature drops to near the temperature at which the rice grains have not started to gelatinize or has just begun to gelatinize, that is, "low temperature boiling". The detached bubbles generated by boiling are used to disturb the rice grains. The rice grains do not stick to each other under the disturbance...

Embodiment 3

[0314] According to an embodiment of the present invention, when the cooking utensil enters the stage of heating and boiling, the vacuum device is first controlled to evacuate the cooking chamber, and then the heating device is controlled to heat, so that the cooking chamber generates boiling bubbles.

[0315] In the cooking control method of the embodiment of the present invention, in the heating and boiling stage, that is, in the range from the first temperature value to the second temperature value, the vacuum device is controlled to vacuum the cooking cavity so that a negative pressure vacuum is formed in the cooking cavity, so that The boiling temperature drops to near the temperature at which the rice grains have not started to gelatinize or has just begun to gelatinize, that is, "low temperature boiling". The detached bubbles generated by boiling are used to disturb the rice grains. The rice grains do not stick to each other under the disturbance, avoiding agglomeration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com