Foam metal, preparation method thereof and cookware

A technology of metal foam and cooking utensils, which is applied in the field of metal foam, can solve the problems of complex pretreatment process, waste of precious metal catalyst, unfriendly environment, etc., and achieve improved coating coverage, simplified pretreatment process, and uniform distribution of pore structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

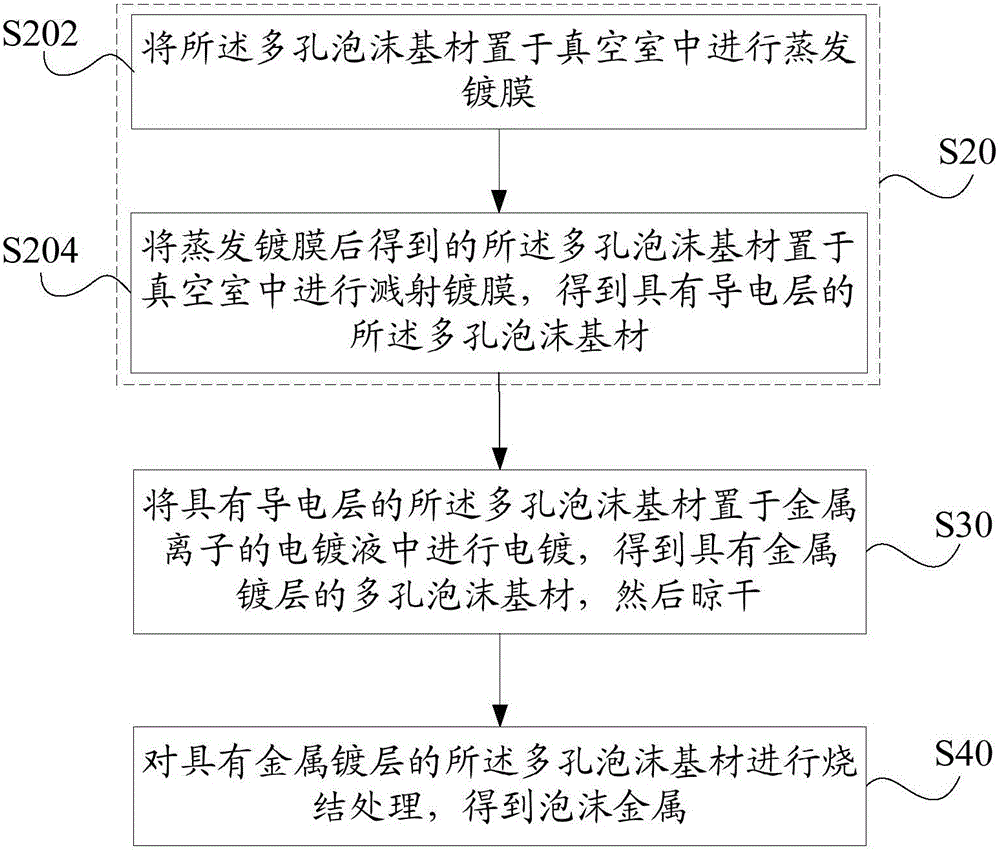

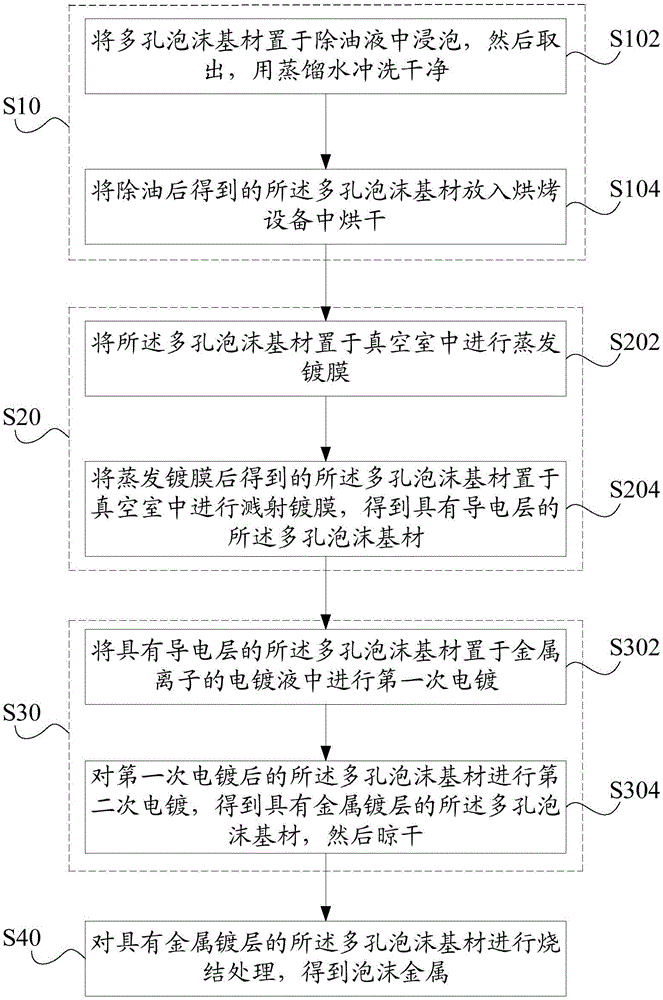

[0052] Such as figure 1 Shown, the preparation method of the metal foam that the embodiment of the first aspect of the present invention provides, comprises:

[0053] Step S20: placing the porous foam substrate in a vacuum chamber for metal coating to obtain a porous foam substrate with a conductive layer;

[0054] Step S30: placing the porous foam substrate with a conductive layer in an electroplating solution of metal ions for electroplating to obtain a porous foam substrate with a metal plating layer, and then drying it;

[0055] Step S40: Sintering the porous foam substrate with metal coating to obtain metal foam;

[0056] Wherein, the step S20 specifically includes:

[0057] Step S202: placing the porous foam substrate in a vacuum chamber for evaporation coating;

[0058] Step S204: placing the porous foam substrate obtained after evaporation and coating in a vacuum chamber for sputter coating to obtain the porous foam substrate with a conductive layer.

[0059] Prefe...

Embodiment 1

[0103] Soak the polyurethane foam material with a porosity of 90% in a degreasing solution at a temperature of 40°C for 8 minutes and then rinse it with distilled water;

[0104] Bake the polyurethane foam material to 130°C for 40 minutes;

[0105] Place the degreased polyurethane foam material in a vacuum chamber for evaporating copper plating. The process parameters for evaporating copper plating are as follows: the background vacuum is 1.0×10 -3 Pa, the evaporation current is 2A, and the evaporation time is 60s;

[0106] Place the evaporated polyurethane foam material in a vacuum chamber for sputtering copper plating. The process parameters of sputtering copper plating are as follows: the background vacuum is 1.0×10 -3 Pa, the sputtering power is 10kW, the argon flow rate is 200sccm, the film formation time is 20min, and the bias voltage is 50V;

[0107] First place the polyurethane foam material obtained after sputtering copper plating in the electroplating solution, pre...

Embodiment 2

[0111] Soak the polyurethane foam material with a porosity of 93% in a degreasing solution at a temperature of 50°C for 9 minutes and then rinse it with distilled water;

[0112] Bake the polyurethane foam material to 140°C for 35 minutes;

[0113] Place the degreased polyurethane foam material in a vacuum chamber for evaporating copper plating. The process parameters for evaporating copper plating are as follows: the background vacuum is 1.5×10 -3 Pa, the evaporation current is 4A, and the evaporation time is 45s;

[0114] Place the evaporated polyurethane foam material in a vacuum chamber for sputtering copper plating. The process parameters of sputtering copper plating are as follows: the background vacuum is 5.0×10 -3 Pa, the sputtering power is 15kW, the argon flow rate is 300sccm, the film formation time is 15min, and the bias voltage is 100V;

[0115] First place the polyurethane foam material obtained after sputtering copper plating in the electroplating solution, pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com