Technique for producing and reducing ilmenite in industrial microwave kiln

A technology of ilmenite and microwave, which is applied in furnaces, fluidized bed furnaces, furnace types, etc., can solve the problems of uneven heating of materials, unstable product quality, and high working power of kilns, so as to shorten the production cycle and improve the quality , The effect of high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

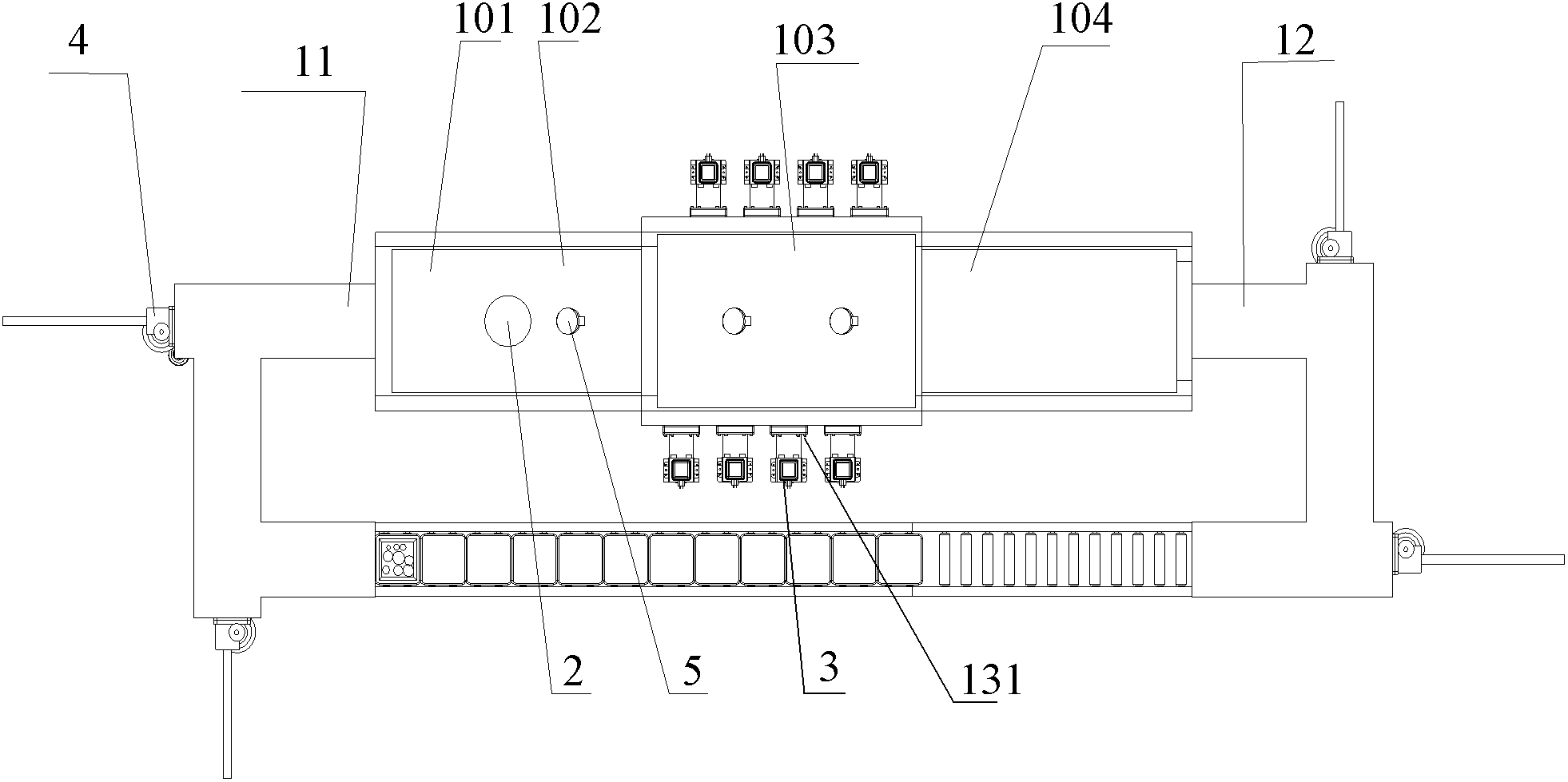

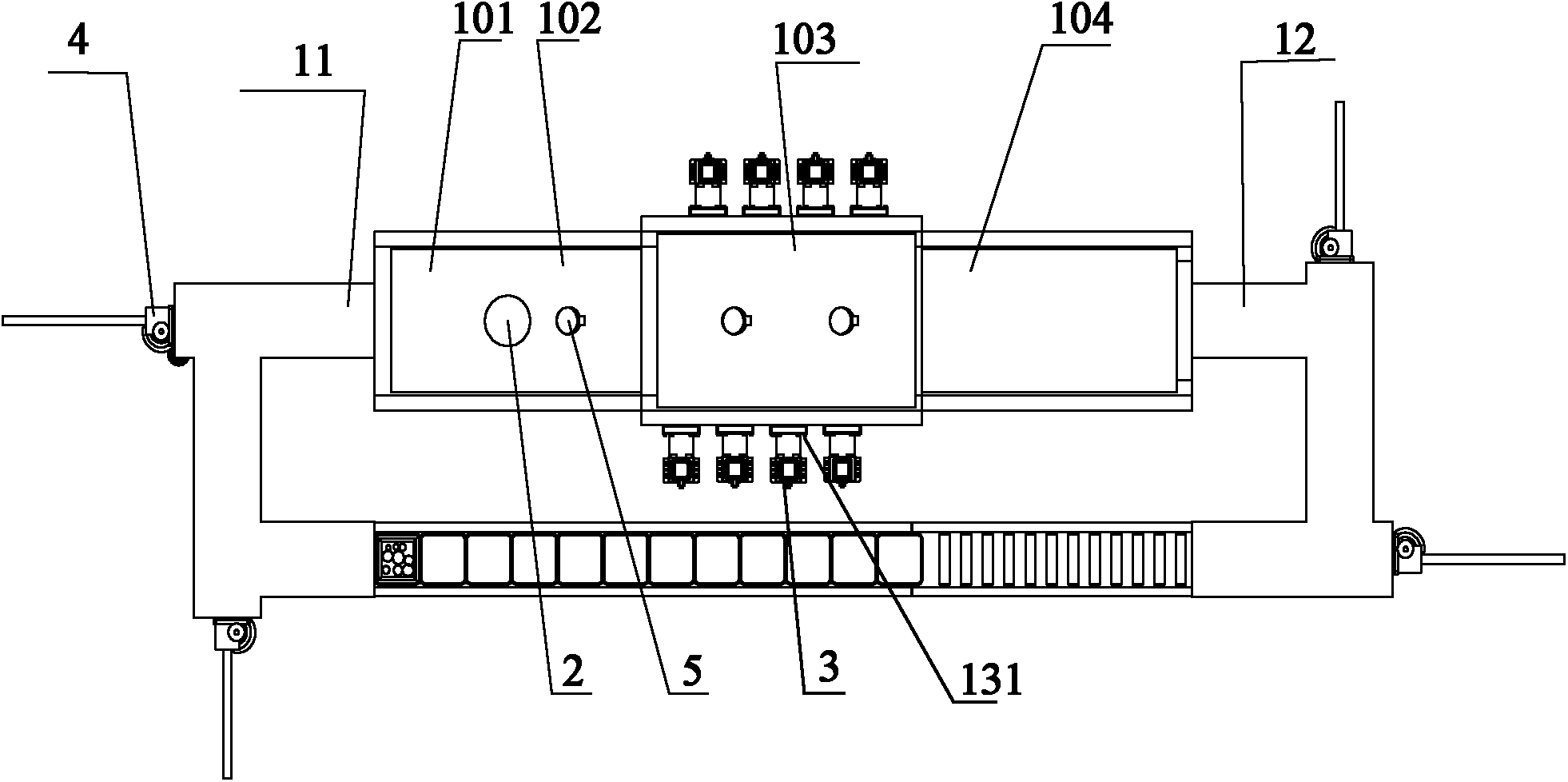

Image

Examples

Embodiment 1

[0051] The raw materials used in this implementation include ilmenite, reducing agent and desulfurizing agent, the weight ratio of ilmenite and reducing agent is 1:0.5, and the dosage ratio of reducing agent and desulfurizing agent is 1:0.07.

[0052] 1. Put the raw materials into the sagger and put them on the setter. Driven by the screw propeller, the raw materials enter the preheating zone along the way and heat for 1 hour. The temperature in the preheating zone is controlled at 300°C.

[0053] 2. The raw material enters the heating zone with the roller table and is heated for 1 hour. The temperature of the heating zone is controlled at 500°C, and the exhaust fan is turned on to extract harmful gases and powder impurities.

[0054] 3. The raw material enters the sintering heat preservation zone along with the roller table and is heated for 1 hour. The magnetron is also controlled to emit microwaves with a frequency of 2450MHz into the sintering heat preservation zone. The mi...

Embodiment 2

[0060] The difference between this embodiment and embodiment 1 is:

[0061] The weight ratio of iron ore and reducing agent in the raw material is 1:0.4, and the consumption ratio of reducing agent and desulfurizing agent is 1:0.05;

[0062] The temperature in the preheating zone is 250°C;

[0063] The temperature in the heating zone is 400°C;

[0064] The temperature of the sintering holding zone is 600°C.

[0065] The product yield rate that present embodiment makes is 92%.

Embodiment 3

[0067] The difference between this embodiment and embodiment 1 is:

[0068] The weight ratio of iron ore and reducing agent in the raw material is 1:0.8, and the consumption ratio of reducing agent and desulfurizing agent is 1:0.06;

[0069] The temperature in the preheating zone is 40°C;

[0070] The temperature in the heating zone is 600°C;

[0071] The temperature of the sintering holding zone is 800°C.

[0072] The product yield rate that present embodiment makes is 94%.

[0073] It can be known from the above results that, compared with the existing ilmenite production process, the method provided by the present invention has lower energy consumption and saves 50% to 70% of electricity consumption, and the product yield is higher than 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com