Automatic noodle cooking machine

A noodle cooking machine and automatic technology, which can be applied to cooking utensils, cooking utensils, household utensils and other directions with a water bath device, can solve the problems of long cooking time, difficulty in guaranteeing the cooked noodles, and failure to meet the requirements of breakfast time, and achieve the cooking time Evenly, reducing hot water splash and scalding hands, and improving the efficiency of noodle cooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

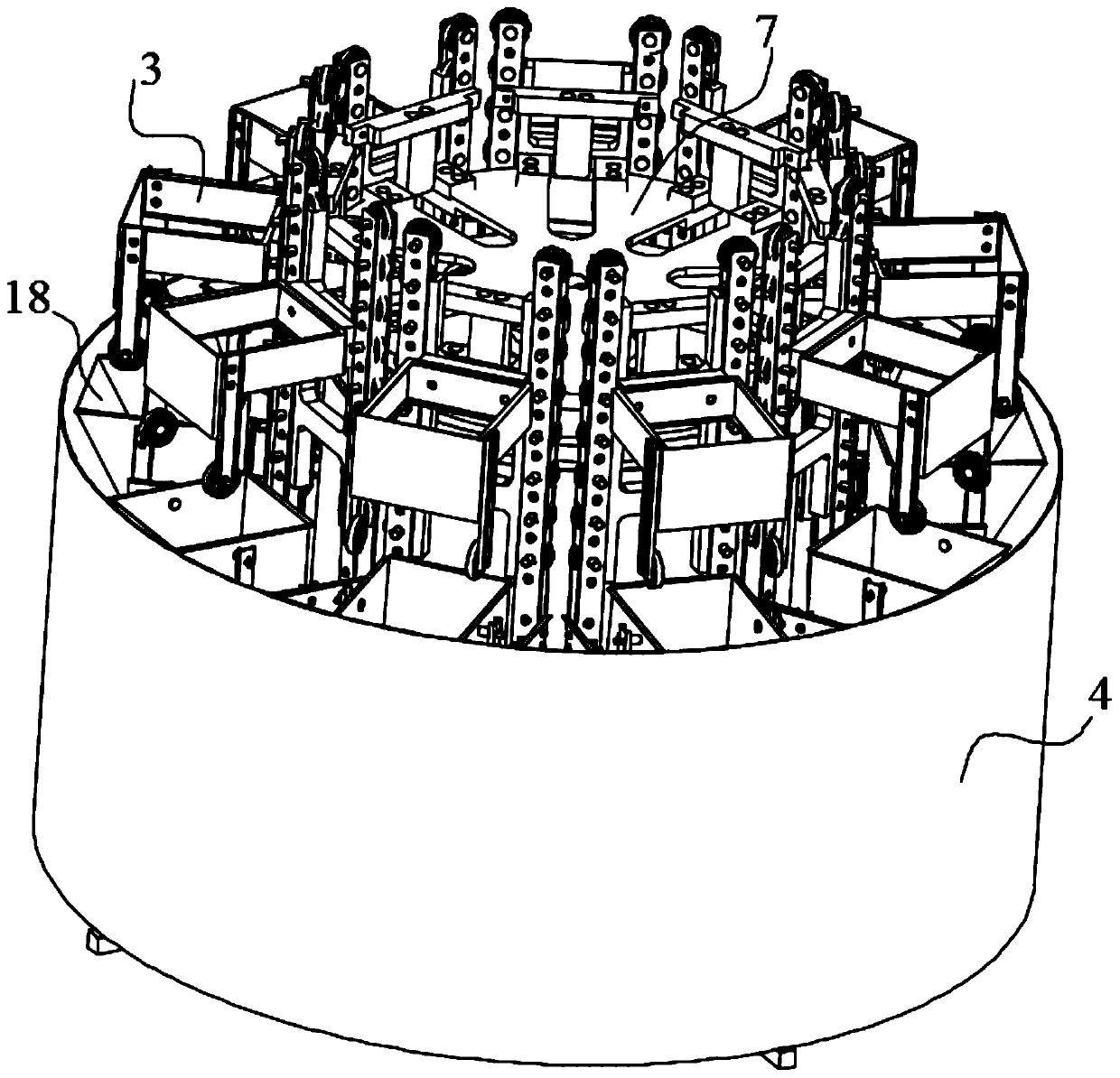

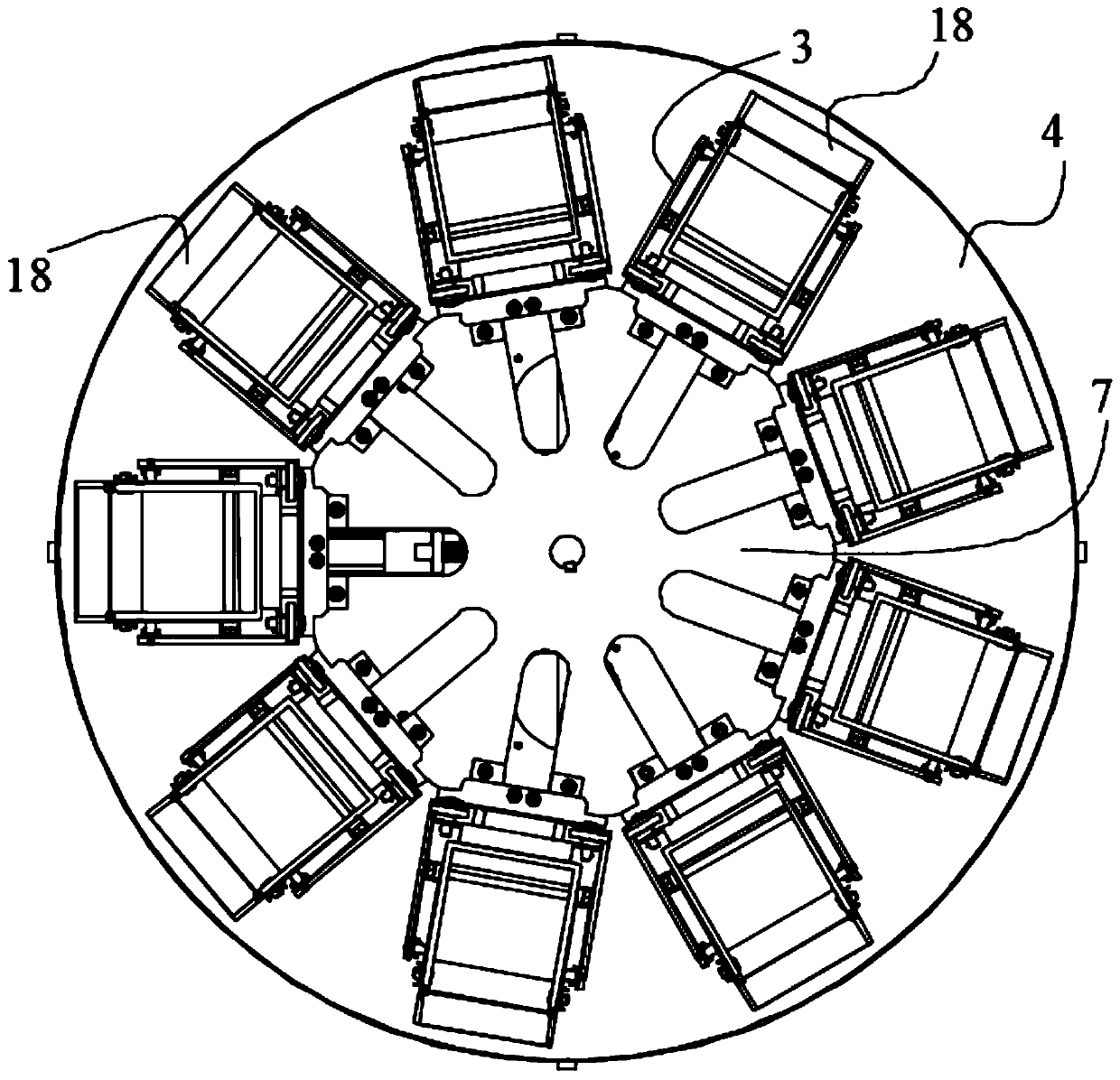

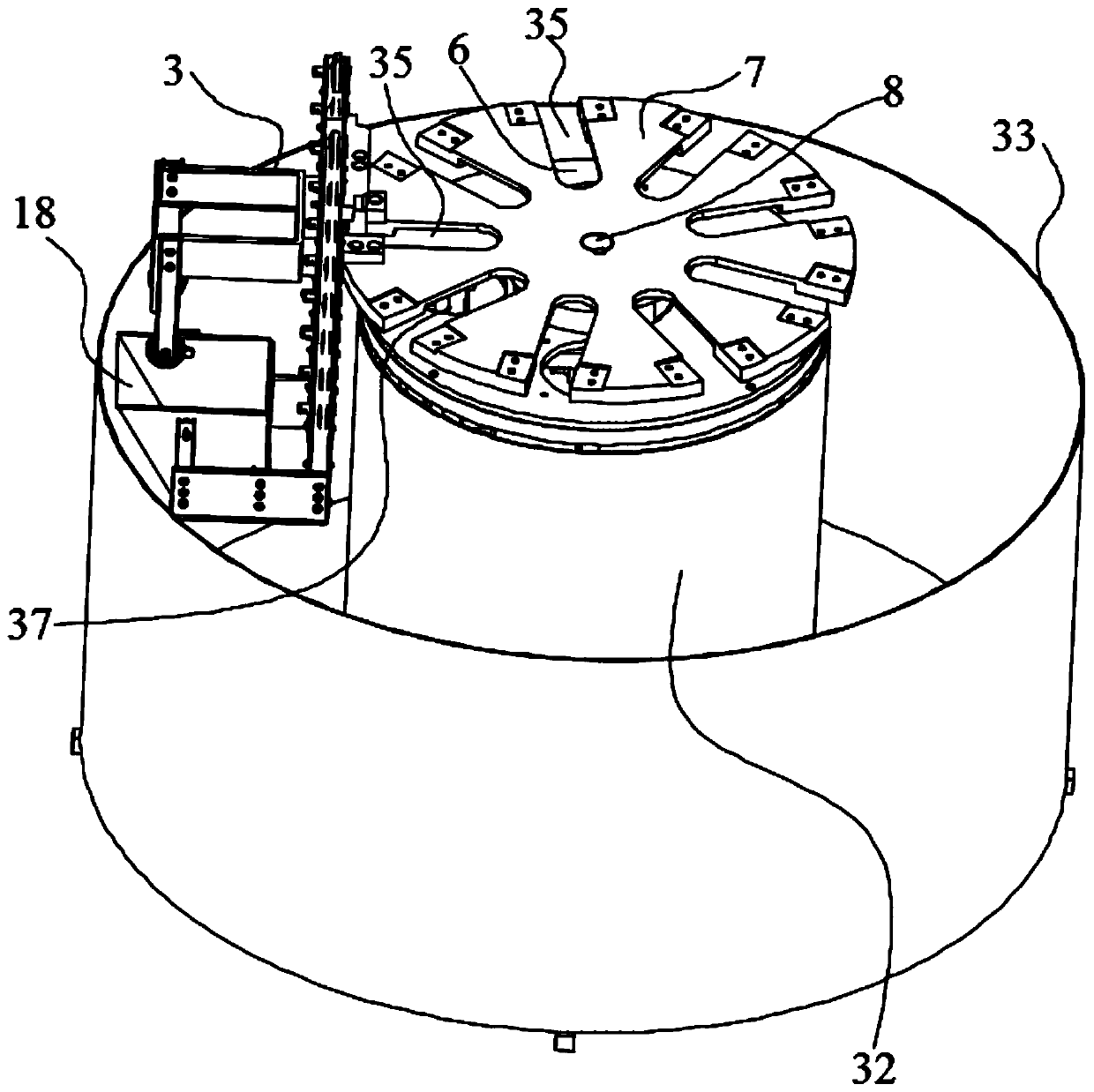

[0033] Such as Figure 1 to Figure 9 Shown, a kind of automatic noodle cooking machine comprises frame 1, noodle pot 4, rotating disc 7, noodle bucket 18, noodle bucket support 3 and lifting mechanism 37, and described rotating disc 7 and noodle pot 4 are respectively installed on The top and bottom of the frame 1, the rotating disk 7 is driven to rotate around its center by a rotating drive device, and there are multiple noodle buckets 18, and the noodle buckets 18 are installed around the rotating disk 7 through the noodle bucket bracket 3. The bucket support 3 includes a fixed bracket 38 and a mobile bracket 39, the bucket 18 is installed on the mobile bracket 39 by the rotating pin 19, the mobile bracket 39 is installed on the fixed bracket 38 by a sliding pair, and the fixed bracket 38 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com