Method for harmless and resourceful treatment of metallurgical hazardous waste

A hazardous waste and recycling technology, applied in the fields of comprehensive utilization of resources and environmental protection, can solve problems such as low added value of products, high environmental risks, and difficulty in recycling, and achieve significant social benefits and economic value, high degree of recycling, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

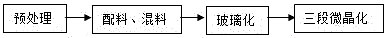

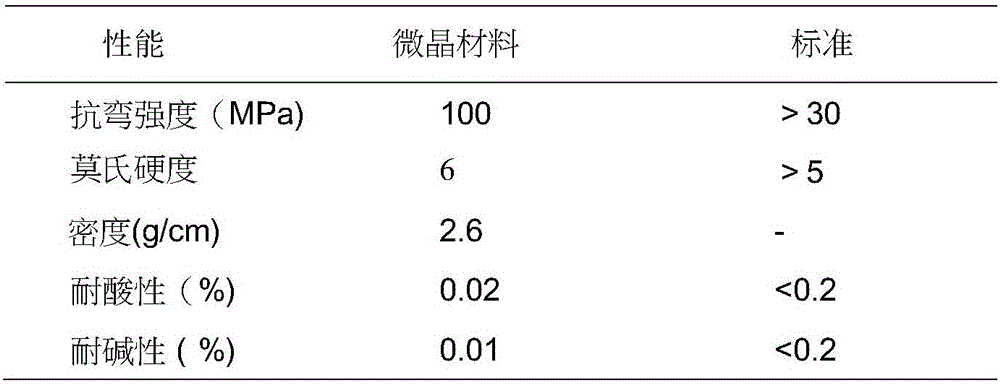

[0032] The method for harmless and resourceful treatment of metallurgical hazardous wastes described in the present invention comprises the following specific steps:

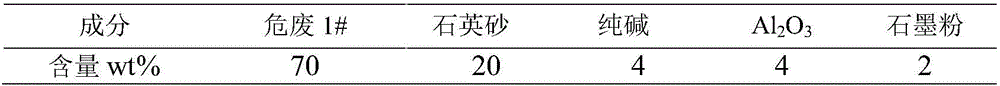

[0033] (1) Pretreatment and batching and mixing: take hazardous waste 1# and auxiliary materials. The microwave output power range for drying hazardous waste slag is 1kW, and the drying time is 20min; the microwave output power range for drying auxiliary materials is 0.5kW, and the drying time is 12min. The dried hazardous waste and auxiliary materials were ball-milled and sieved to 180 meshes, and the under-sieves were taken for batching (see Table 1) and mixing.

[0034] Table 1 Proportion 1#

[0035]

[0036] (2) Vitrification: Vitrification is prepared by heating in an electric furnace and heating to 1250°C for 3 hours;

[0037] (3) Microcrystallization: The three-stage microcrystallization heat treatment method is the temperature range of the first stage: 1250 to 1100°C, the cooling rate is 8°C / min; the...

Embodiment 2

[0045] The method for harmless and resourceful treatment of metallurgical hazardous wastes described in the present invention comprises the following specific steps:

[0046] (1) Pretreatment and batching and mixing: take hazardous waste 2# and auxiliary materials, the microwave output power range for drying hazardous waste slag is 2kW, and the drying time is 10min; the microwave output power range for drying auxiliary materials is 1kW, and the drying time is 5min. The dried hazardous waste and auxiliary materials were ball-milled and sieved to 160 meshes, and the under-sieves were taken for batching (see Table 4) and mixing.

[0047] Table 4 Proportion 2#

[0048]

[0049] (2) Vitrification: vitrification is prepared by heating in an electric furnace and heating to 1350°C for 2 hours;

[0050] (3) Microcrystallization: The three-stage microcrystallization heat treatment method is the temperature range of the first stage: 1350 to 1120°C, the cooling rate is 8°C / min; the mi...

Embodiment 3

[0057] The method for harmless and resourceful treatment of metallurgical hazardous wastes described in the present invention comprises the following specific steps:

[0058] (1) Pretreatment and batching and mixing: take hazardous waste 3# and auxiliary materials, the microwave output power range for drying hazardous waste slag is 1.5kW, and the drying time is 15min; the microwave output power range for drying auxiliary materials is 0.7kW, and the drying time is 9min . The dried hazardous wastes and auxiliary materials were ball milled and sieved with a mesh number of 180, and the undersize was taken for batching (see Table 7) and mixing.

[0059] Table 7 ratio 3#

[0060]

[0061]

[0062] (2) Vitrification: vitrification is prepared by microwave heating, heating to 1450°C for 30 minutes;

[0063] (3) Microcrystallization: The three-stage microcrystallization heat treatment method is the temperature range of the first stage: 1450 to 1100°C, the cooling rate is 15°C / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com