Heparin sodium production equipment based on secondary enzymolysis method

A production equipment, heparin sodium technology, applied in the field of biotechnology, can solve the problems of inconvenient cleaning, uneven temperature, high height, etc., and achieve the effects of increasing maintenance costs, improving preparation efficiency, and enhancing reaction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

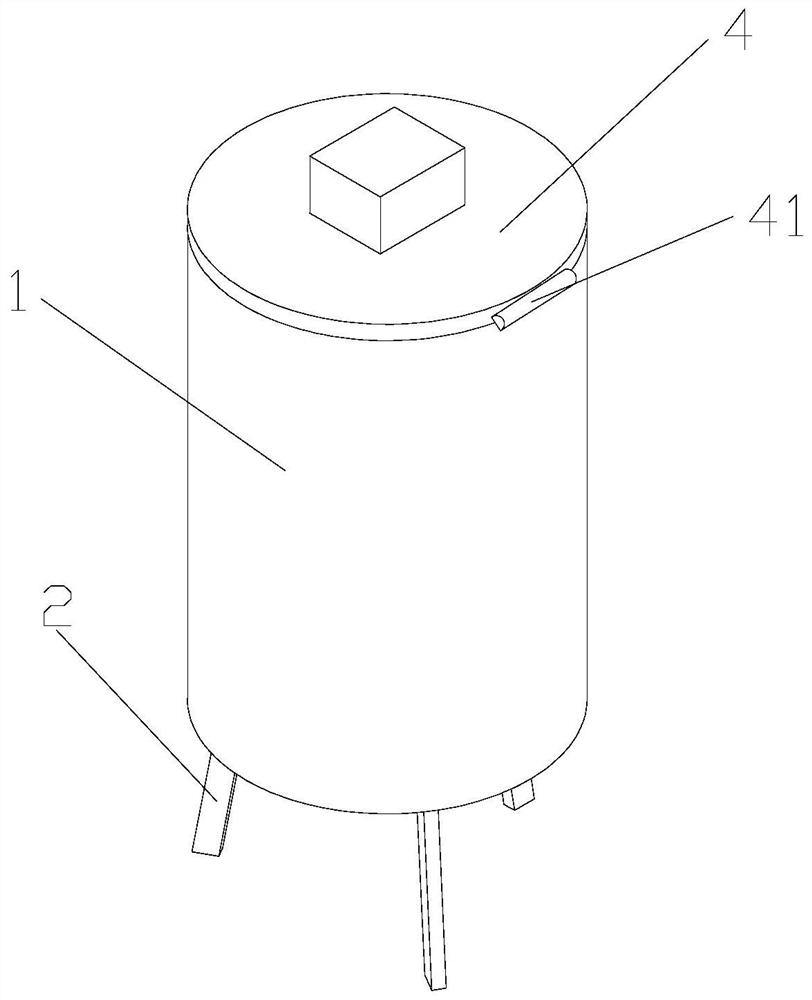

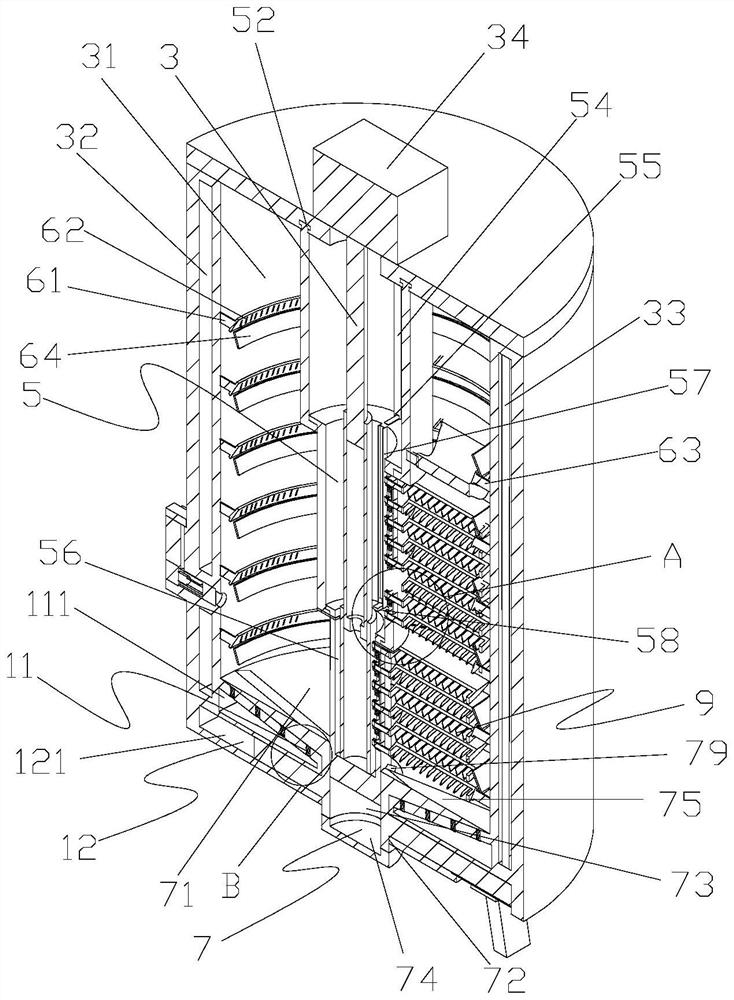

[0032] Such as Figure 1-15 As shown, a heparin sodium production equipment based on the secondary enzymatic hydrolysis method includes a cylinder body 1, a foot 2, a stirring device 3, a cover plate 4, a first rotating part 41, and a detection structure 8; the cylinder body is a high-narrow type cylinder body structure, the legs 2 are arranged under the cylinder, the stirring device 3 is set in the cylinder, the cover plate 4 is arranged above the cylinder, the first rotating member 41 is used to connect the cylinder and the cover, The first rotating part is a hinged structure, which is used to hinge the cover plate and the cylinder body. The detection structure 8 is arranged on one side of the cylinder body. The detection structure here is a prior art, which is an existing conventional means, and will not be repeated here. The stirring device 3 includes a stirring chamber 31, a first cavity 32, a heating pipe 33, a motor 34, a telescopic stirring structure 5, a first auxilia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com