Hot in-place recycling heating temperature control system and control method

A temperature control system and heating temperature technology, applied in the direction of temperature control, control/regulation system, non-electric variable control, etc., can solve the problem of large fluctuation of road heating temperature, incomplete road heating, intermittent and subjective acquisition. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

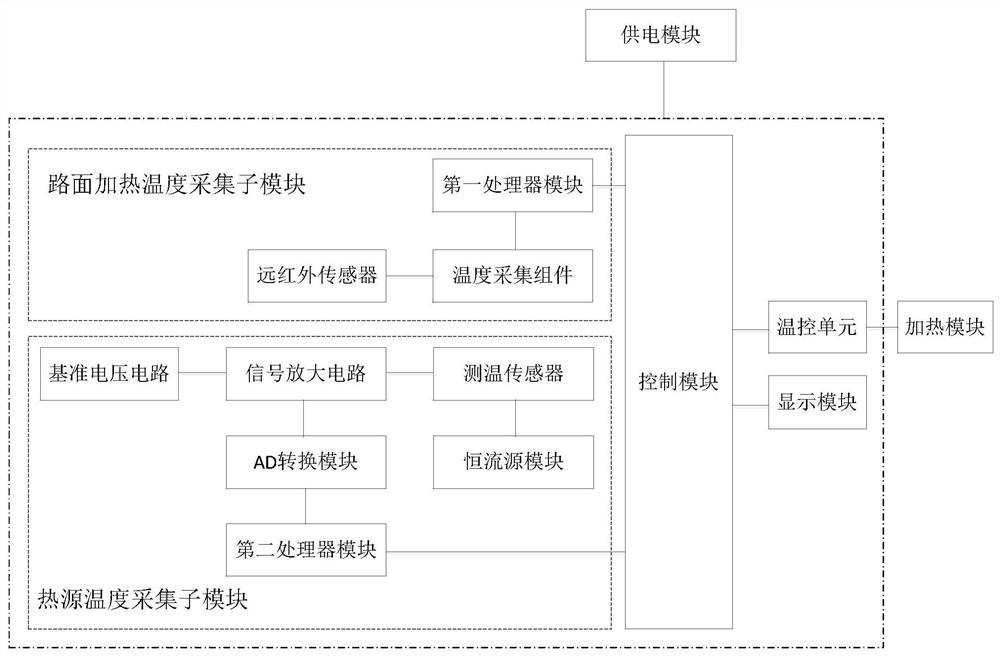

[0033] Such as figure 1 As shown, the present embodiment 1 provides an in-situ thermal regeneration heating temperature control system, including: a control module, a first data acquisition module, a second data acquisition module and a heating device; wherein the first data acquisition module is suitable for real-time collect road surface heating data and send it to the control module; the second data collection module is adapted to collect the heating temperature of the heating device in real time and send it to the control module; Heating temperature and road surface heating data are required to obtain the required heating heat source temperature, and control the heating device to heat the road surface according to the required heating heat source temperature; and the control module is suitable for comparing the required heating heat source temperature and real-time Collect the heating temperature, and control the heating device to adjust the heating temperature of the road...

Embodiment 2

[0070] Such as image 3 As shown, on the basis of Embodiment 1, this Embodiment 2 provides a method for controlling the heating temperature of in-situ thermal regeneration, including: collecting road surface heating data in real time through the first data acquisition module, and sending it to a control module; The second data acquisition module collects the heating temperature of the heating device in real time and sends it to the control module; through the control module, according to the preset road surface heating temperature and road surface heating data, the required heating heat source temperature is obtained, and the heating device is controlled The road surface is heated according to the heat source temperature required for heating; and the temperature of the heat source required for heating is compared with the heating temperature collected in real time through the control module, and the heating device is controlled to adjust the heating temperature of the road surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com