Tea re-drying machine

A drying machine and tea technology, which is applied in the direction of drying machine, local stirring dryer, static material drying machine, etc., can solve the problem of darkening of tea color and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

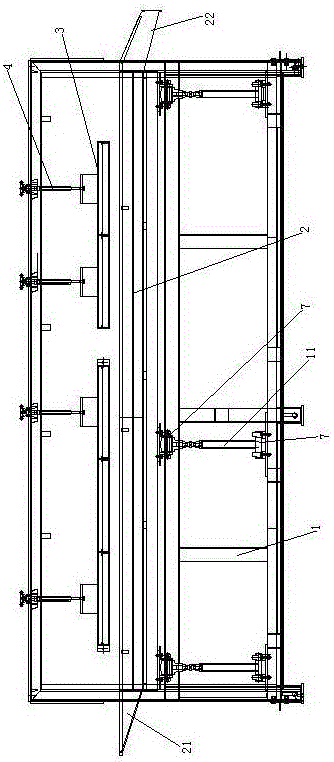

[0029] Embodiment one, see figure 1 , a tea re-drying machine, including a frame 1, a tank body 2 and a heating mechanism 3.

[0030] The tank body 2 is swingably supported on the frame 1 by at least two support swing bars 11 . The upper end of the support swing rod 11 is connected with the tank body through a vibration-increasing structure 7, and the lower end is hinged with the frame 1 through a vibration-increasing structure 7. The groove body 2 is a groove extending in the left-right direction. The left end of the tank body 2 is high and the right end is low. The left end of the tank body 2 is provided with a feeding port 21 . The right end of the tank body 2 is provided with a discharge port 22 .

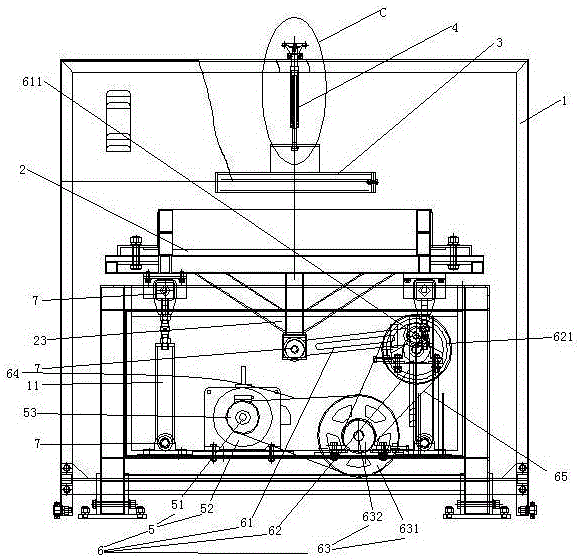

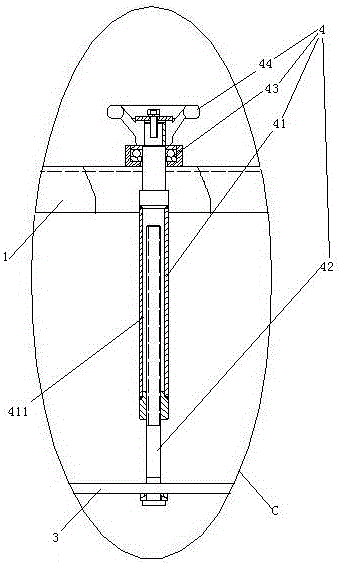

[0031] The heating mechanism 3 is a drying lamp positioned above the tank body 2 and irradiated toward the tank body. The heating mechanism 3 is suspended from the frame 1 in a liftable manner through at least two lifting mechanisms 4 .

[0032] see figure 2, the presen...

Embodiment 2

[0037] Embodiment two, the difference with embodiment one is:

[0038] see Image 6 , the motor shaft 51 is supported by the motor housing 52 through two bearings 55 . An oil filling chamber 56 is formed between the motor housing 52 and the two bearings 55 . A first gear 58 and a second gear 57 are arranged in the oil filling chamber 56 . The first gear 58 and the second gear 57 mesh together. The first gear 58 is connected with the motor shaft 51 . The second gear 57 is rotationally connected with the motor housing 52 through a short shaft 571 .

[0039] see Figure 7 , the first gear 58 is provided with a refueling mechanism 8 . The number of refueling mechanisms 8 is equal to the number of teeth of the first gear 58 .

[0040] see Figure 8 , The refueling mechanism 8 includes an oil outlet 81 , an air supply port 82 , a sealing head 83 , a first spring 84 , a cylinder 85 and a piston 86 . The oil outlet 81 and the air supply port 82 of the same fueling mechanism a...

Embodiment 3

[0045] Embodiment three, the difference with embodiment two is:

[0046] see Figure 10 , The tank body 2 is provided with an inner cavity 25 . The inner cavity 25 is provided with an air outlet hole 26 which penetrates to the groove surface 27 of the groove body (that is, the surface supporting the tea leaves during use).

[0047] The air outlet hole 26 is staggered with the anti-slip groove 24, which can more effectively promote the tea leaves to roll under the action of the anti-slip groove. The inner chamber 25 is provided with a roller 9 . The roller 9 is a tubular structure. An accelerator lever 91 is arranged in the roller 9 . The acceleration lever 91 can accelerate the rolling of the roller 9 in the inner cavity 25 . The extending direction of the roller 9 is the same as that of the tank body 2 .

[0048] see Figure 11 , A plurality of air grooves 92 are provided on the peripheral surface of the roller 9 . The air grooves 92 extend axially along the circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com