Textile product cleaning and drying device

A drying device and textile technology, applied in textiles and papermaking, equipment configuration for processing textile materials, processing of textile materials, etc., can solve the problems of energy waste, cumbersome steps, and reduce the quality of textiles, and achieve simple structure and high utilization rate , the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

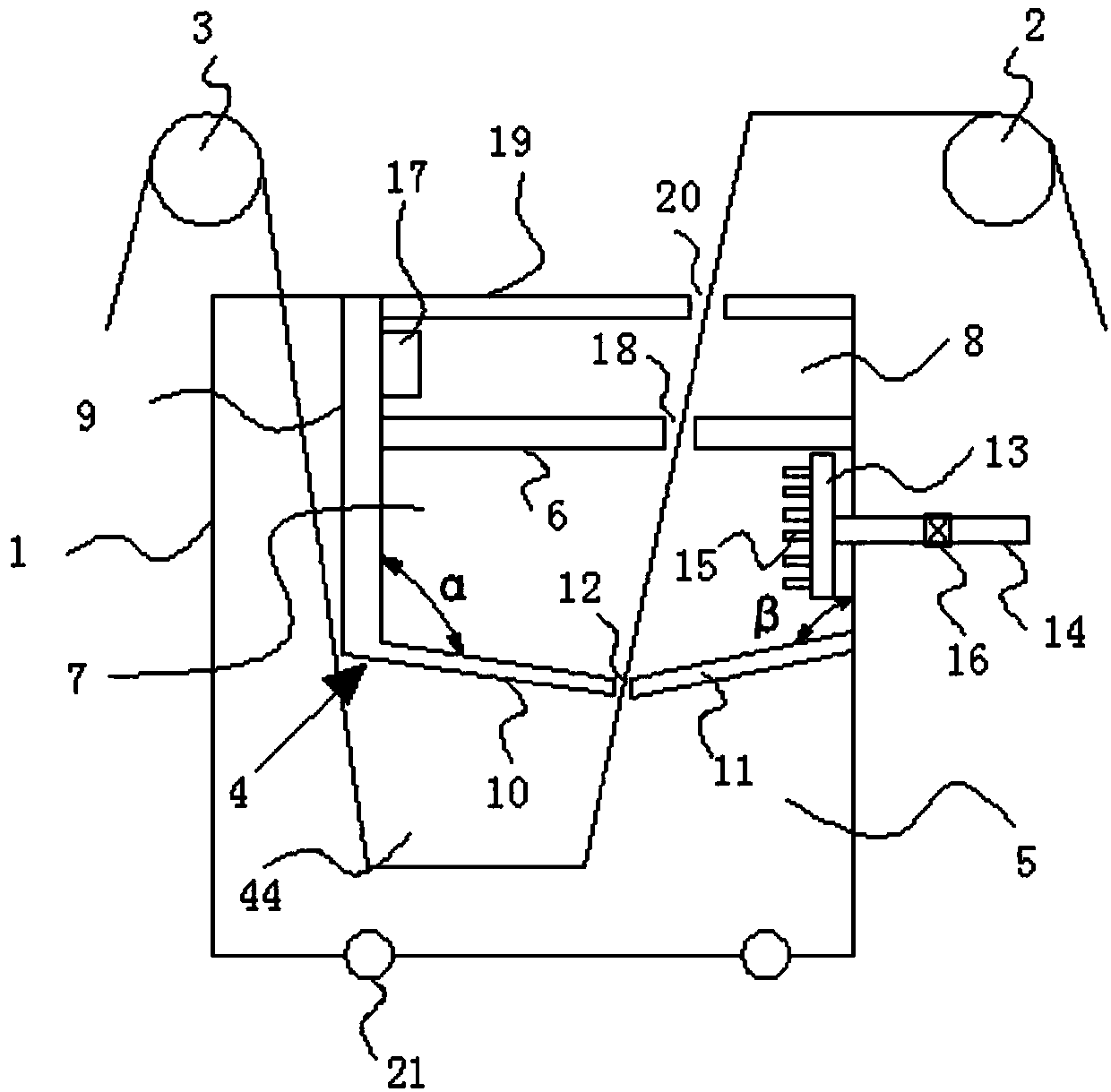

[0027] Embodiment: a kind of textile washing and drying device, such as figure 1 As shown, it includes a tank body 1, a receiving roller 2 arranged on one side of the tank body, and a discharge roller 3 on the other side. A partition is sealed with three sides of the tank body to divide the tank body into a cleaning area 5 and a non-cleaning area, a cleaning agent is provided in the cleaning area, and a second partition is provided in the non-cleaning area 6. The second partition divides the non-cleaning area into a blowing area 7 and a drying area 8, and the drying area is located directly above the blowing area;

[0028] Described first dividing plate comprises vertical side plate 9 and the deflector that is positioned at the bottom of described blowing area, and described deflector comprises left deflector 10 and right deflector 11, and described left deflector and The vertical side panels are connected, the right deflector is connected to the side wall of the tank, the le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com