Rotary autoclaved drying kettle

A technology of drying and rotary joints, which is applied in the production field of rotary autoclaved drying kettles and α-type hemihydrate gypsum, can solve the problems of long production cycle, large energy consumption, low production efficiency, etc., and achieve easy programming and automation, High drying efficiency and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

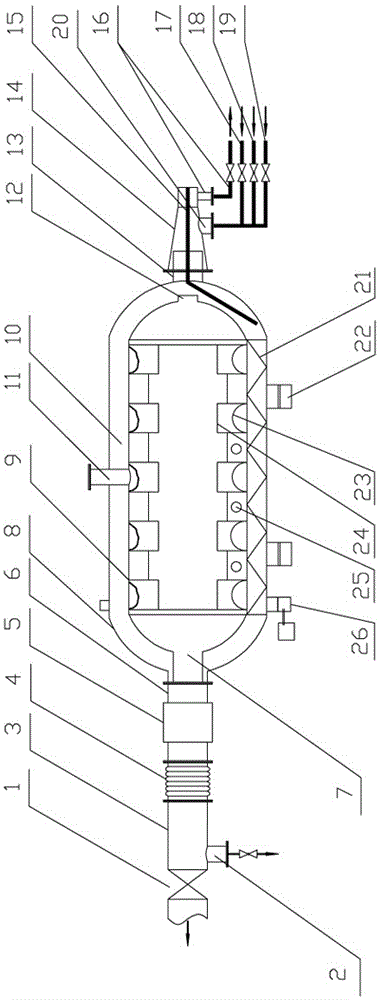

[0019] see figure 1 , the present invention has a horizontally placed cylindrical shell 8, which is equipped with a rotating supporting wheel set 22 and a rotating drive mechanism 26, and is characterized in that: one end of the shell 8 is provided with an intake main pipe 13, and the other end is provided with a discharge air pipe 6, A rotary joint A14 is set on the air intake pipe, and the main air intake pipe 20 and the condensed water discharge pipe 16 are installed on the rotary joint A14; A steam insulation interlayer 10 is formed, the tail end of the interlayer is closed, the front end of the interlayer communicates with the intake main pipe 13, the front end of the storage tank 9 is provided with an air inlet 12 communicated with the intake main pipe 13, and the rear end is provided with a discharge The air port 7 communicates with the discharge air pipe 6; a feeding pipe 11 is installed on the housing 8 and extends into the storage tank 9, and a sealing cover is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com