Apparatus and method for automatic filtering tobacco liquid

A technology of automatic filtration and material use, applied in the direction of mobile filter element filter, filtration separation, separation method, etc., to achieve the effects of saving work space and time, reducing the risk of production pollution, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1 A device and method for automatic filtration of tobacco feed liquid

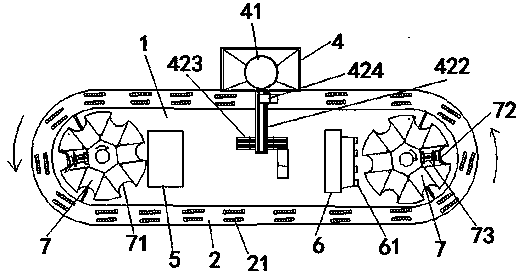

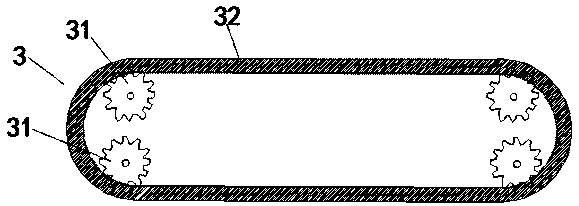

[0053] 1. Automatic filter equipment for cigarette material liquid

[0054] Such as figure 1 As shown, the automatic filter equipment for tobacco material liquid includes a workbench 1, a conveying track 2 for conveying the filter screen and a rotary mechanism 3. There is a filter mechanism 4, a cleaning mechanism 5 and a drying mechanism 6; the filter mechanism 4 is provided with a transfer mechanism 42; the conveying track 2 is arranged on the upper surface of the workbench 1, the rotary mechanism 3 is arranged inside the workbench 1, and the conveying track 2 is arranged above and connected to the rotary mechanism 3, and the rotary mechanism 3 drives the conveying track 2 to rotate at a constant speed along the circular path of the worktable 1. A plurality of magnetic adsorption pieces 21 for fixing the filter net are arranged on the conveying track 2 .

[0055] The transfer mechanism ...

Embodiment 2

[0069] Example 2 An automatic filtering device for tobacco material liquid

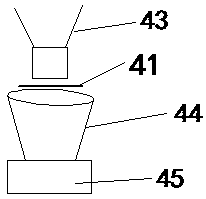

[0070] As a further improvement to Embodiment 1, the transfer mechanism 42 of this embodiment includes a manipulator 421 for pushing the filter on the conveying track 2 to the filter accommodating tank 41 and a displacement control device for driving the manipulator 421 to reciprocate.

[0071] Such as Figure 5 As shown, the displacement control device is composed of an X-axis moving assembly 423, a Y-axis moving assembly 422 and a Z-axis moving assembly 424. The manipulator 421 is arranged on the Z-axis moving assembly 424 through a connecting piece, and the manipulator is driven by the Z-axis moving assembly 424. 421 reciprocates up and down; the Z-axis moving assembly 424 is arranged on the guide rail of the Y-axis moving assembly 422 through a slider, and the motor on the Y-axis moving assembly 422 drives the Z-axis moving assembly 424 to reciprocate along its guide rail direction through the sli...

Embodiment 3

[0073] Example 3 An automatic filtering device for tobacco material liquid

[0074] As a further improvement to Embodiment 1 and Embodiment 2, the drive mechanism provided under the workbench 1 in this embodiment, such as Figure 6 shown.

[0075] This driving mechanism comprises driving cylinder 8, transmission rod 81, stop rod 82, rotating gear 83 and rotating shaft 84, and one end of transmission rod 81 is connected and makes transmission rod 81 do linear reciprocating drive cylinder 8, and the other end is connected with stop rod. 82 are hinged; transmission rod 81, stop rod 82 are positioned at the both sides of rotating gear 83, and rotating gear 83 meshes with the tooth rack of transmission rod 81, the rack of stop rod 82 simultaneously; Rotation shaft 84 passes through rotating gear 83 and with The turntable 7 is fixedly connected, and the transmission rod 81 meshes with the rotation gear 83 and drives the rotation shaft 84 to rotate, thereby driving the turntable 7 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com