Net band transmission type vacuum continuous drying device and net band transmission type drying device

A drying device and transmission-type technology, which is applied to drying solid materials, heating to dry solid materials, and non-heating to dry solid materials, etc., can solve the problems of material grain skin cracks, insufficient inner dryness, and large space size, etc. To achieve the effect of ensuring drying consistency, wide application range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

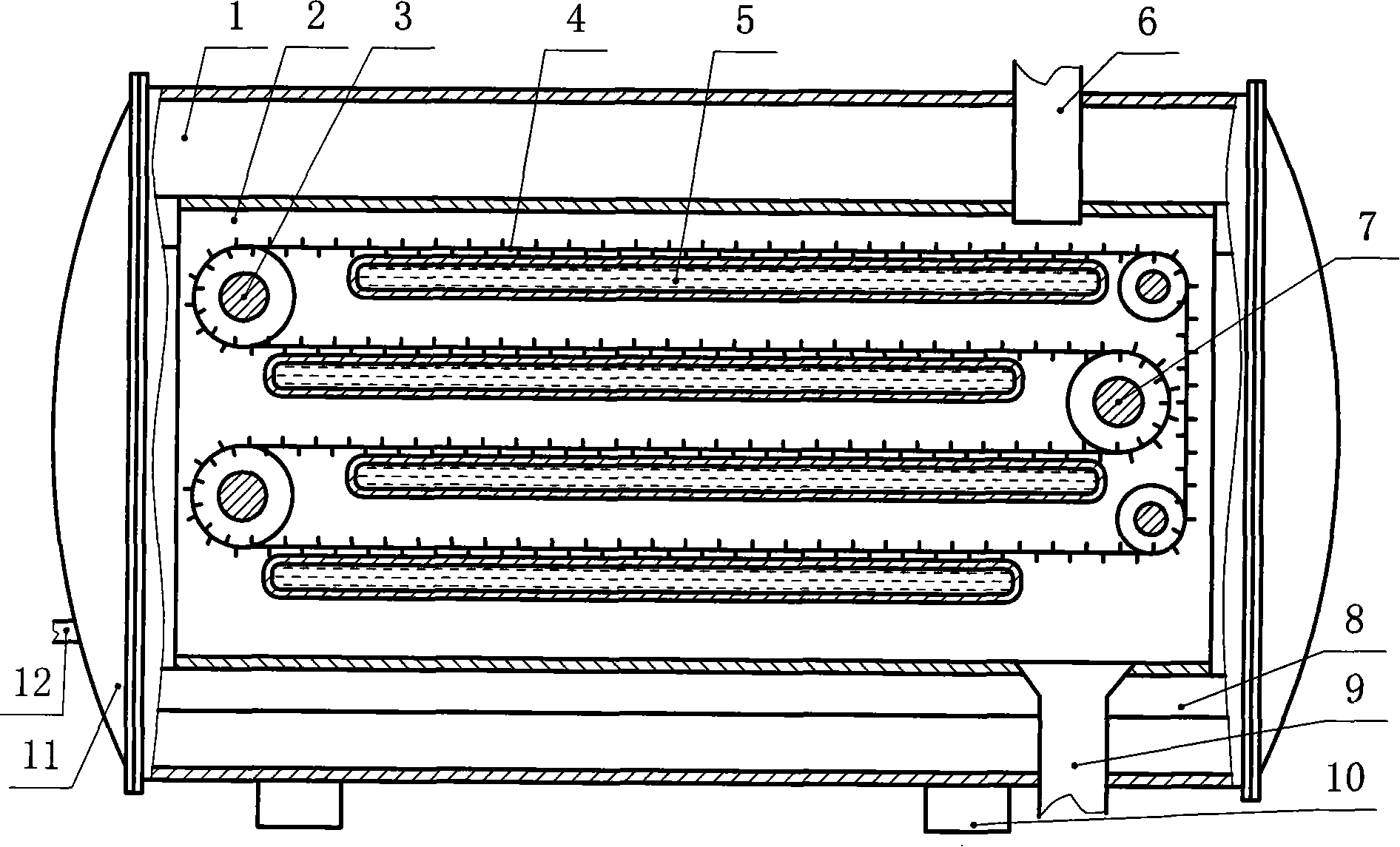

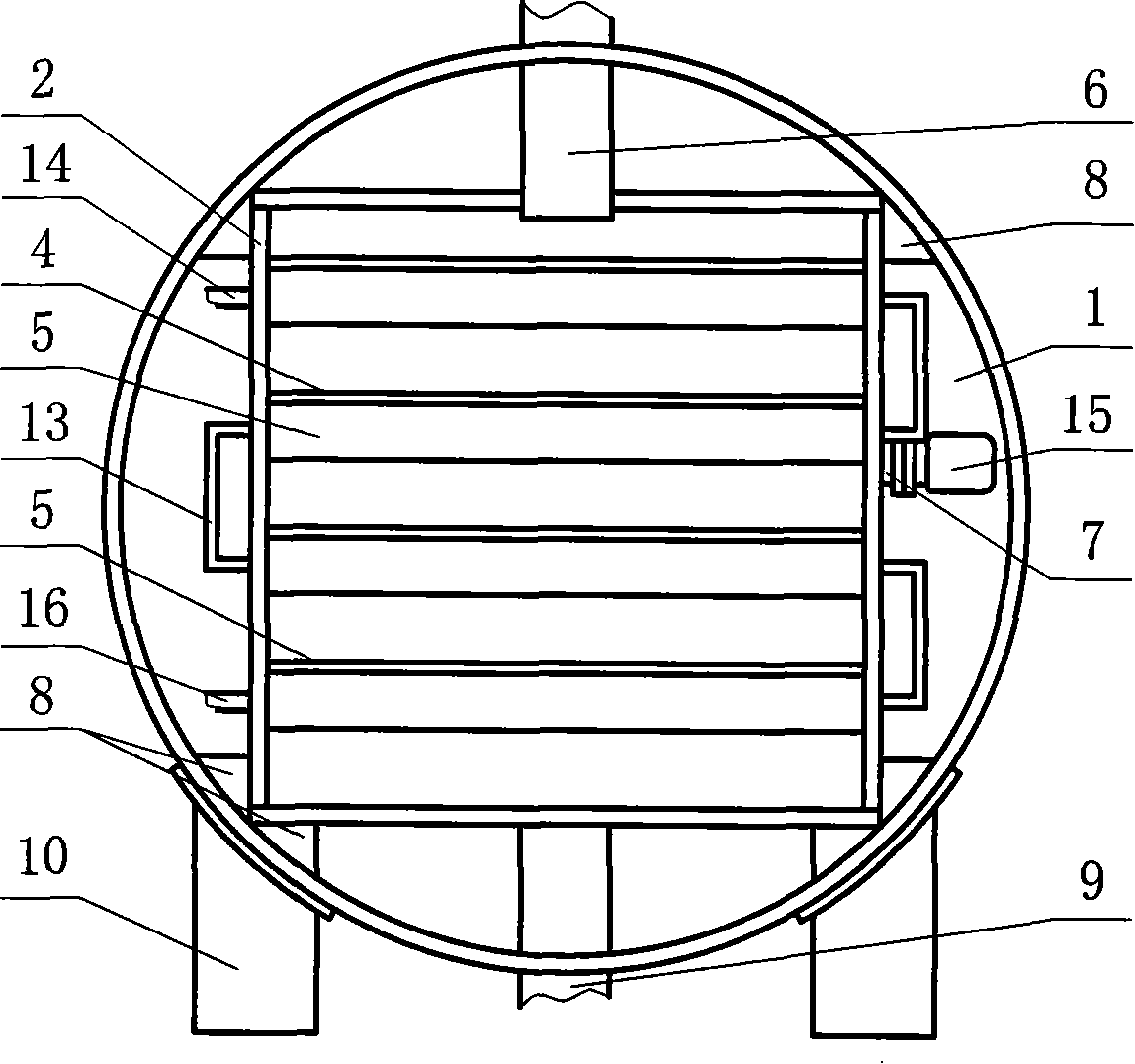

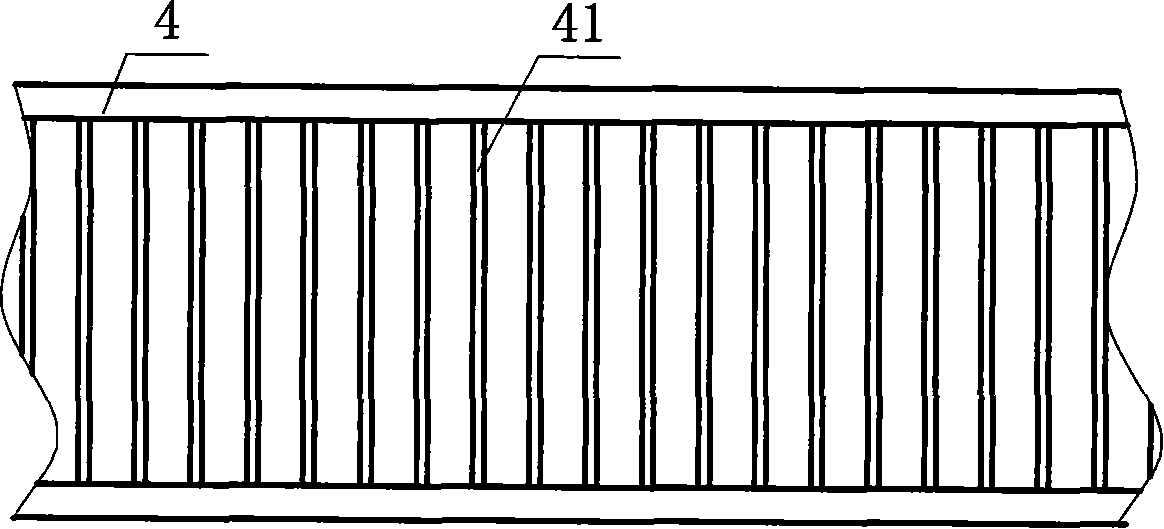

[0032] Embodiment one: see figure 1 , figure 2 , image 3 , Figure 4 , among the figure, the net-belt transmission type vacuum continuous drying device contains cylindrical shell 1, and the two ends of cylindrical shell 1 are respectively provided with spherical end cap 11, and one end cap (also can be on the body wall of cylinder Above) is provided with a suction pipe 12, the suction pipe 12 is connected to a vacuum pump, the axis of the cylindrical cylinder 1 is placed horizontally, a square silo 2 is set inside the cylindrical cylinder 1, and the two body walls of the square silo 2 There are four layers of flat water pipes 5 installed between them, and the uppermost flat water pipe 5 communicates with the water inlet pipe 14, the lowermost flat water pipe 5 communicates with the outlet pipe 16, and the middle flat water pipe 5 realizes end to end through the connecting pipe 13. Connected, so that the flow path of the water flow is a turn-back bow shape, and the water i...

Embodiment 2

[0037] Embodiment two: see Figure 5 , Image 6 , the present embodiment is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that the specific structure of the endless mesh belt 4 is different. In the present embodiment, the endless mesh belt 4 contains two toothed conveyor belts, The two toothed transmission side belts are meshed with the gears at both ends of the rotating roller respectively, and a rotating plate is arranged between the two toothed transmission side belts, and a certain number of discharge holes 42 arranged according to a certain rule are arranged on the rotating plate , so that the material falls on the surface of the flat water pipe, suitable for drying granular materials.

Embodiment 3

[0038] Embodiment three: see Figure 7 , the present embodiment is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that the structure of the endless mesh belt 4 is different. In the present embodiment, the endless mesh belt 4 contains two toothed conveyor belts, and Two toothed conveying side belts mesh with the gears at both ends of the rotating roller respectively, and a flat net is installed between the two toothed conveying side belts. The mesh 43 on the flat net is convenient for materials to fall on the surface of the flat water pipe, which is suitable for particle packaging. Material drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com